Wear-resistant and corrosion-resistant petroleum pipeline and preparation method thereof

An oil pipeline and anti-corrosion technology, which is applied in the direction of pipeline protection, pipeline damage/wear prevention, pipeline anticorrosion/rust protection, etc., can solve the problems of shortening the mission life of pipe fittings, public and environmental hazards, oil pipeline wear, etc., and achieve reduction Adhesion and deposition, improved hydrophobicity, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, a wear-resistant and corrosion-resistant petroleum pipeline is produced through the following steps:

[0039] (1) Pretreatment: first spray acetone solution on the surface of the inner wall of the steel pipe body to remove the oil on the inner surface; then use an inner hole sandblasting gun to perform sandblasting and coarsening treatment on the inner wall of the steel pipe body. The pressure is 0.6MPa, the sandblasting distance is 150 mm, and the sandblasting effect is better if there is no oxide layer and rust on the inner wall surface of the pipeline. Sandblasting roughening can remove the oxide layer and rust on the inner surface of the steel pipe body, reveal a bright and clean inner surface, retain the roughness of sandblasting, and provide a good rough surface for coating adhesion. After sandblasting, the roughness of the inner surface is Between 5μm;

[0040] (2) Fixing the pipe body: Immediately fix the steel pipe body treated in step (1) ...

Embodiment 2

[0048] The differences between this embodiment and Embodiment 1 are:

[0049] In step (1), the roughness of the inner surface after sandblasting is between 4 μm;

[0050] In steps (3) to (5) and (7), after each spraying cycle, the inner hole spray gun moves 10mm to the other end along the axial direction of the steel pipe body,

[0051] In step (6), the stirring speed is 150 r / min.

[0052] All the other are the same as embodiment one.

Embodiment 3

[0054] The differences between this embodiment and Embodiment 1 are:

[0055] In step (1), the roughness of the inner surface after sandblasting is between 6 μm;

[0056] In steps (3)-(5) and (7), after each round of spraying, the inner hole spray gun moves 15mm to the other end along the axial direction of the steel pipe body,

[0057] In step (6), the stirring speed is 200 r / min.

[0058] All the other are the same as embodiment one.

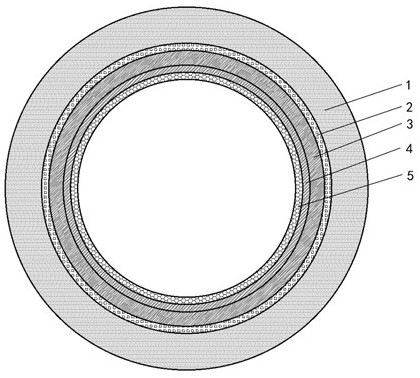

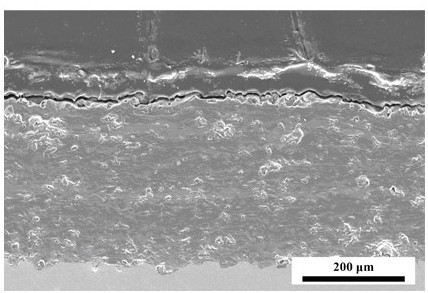

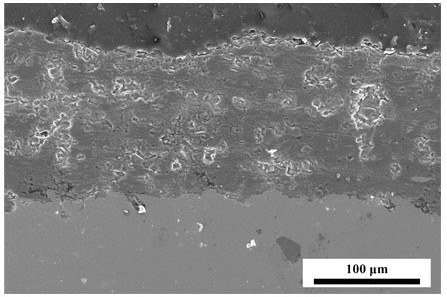

[0059] Prepared by the above method as figure 1 The wear-resistant and corrosion-resistant petroleum pipe shown is specifically that the inner wall of the steel pipe body 1 is sequentially provided with a NiCrAlY layer 2, a first ceramic layer 3, a second ceramic layer 4 and a polytetrafluoroethylene layer 5 from the outside to the inside. The first ceramic layer 3 and the second ceramic layer 4 are made of Al with a particle size of 32-38 μm and an average particle size of 35 μm. 2 o 3 -13%TiO 2 Composed of particles, the porosity of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com