Heterojunction solar cell and interfacing processing method and preparing technology thereof

A technology of solar cells and manufacturing processes, applied in circuits, photovoltaic power generation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

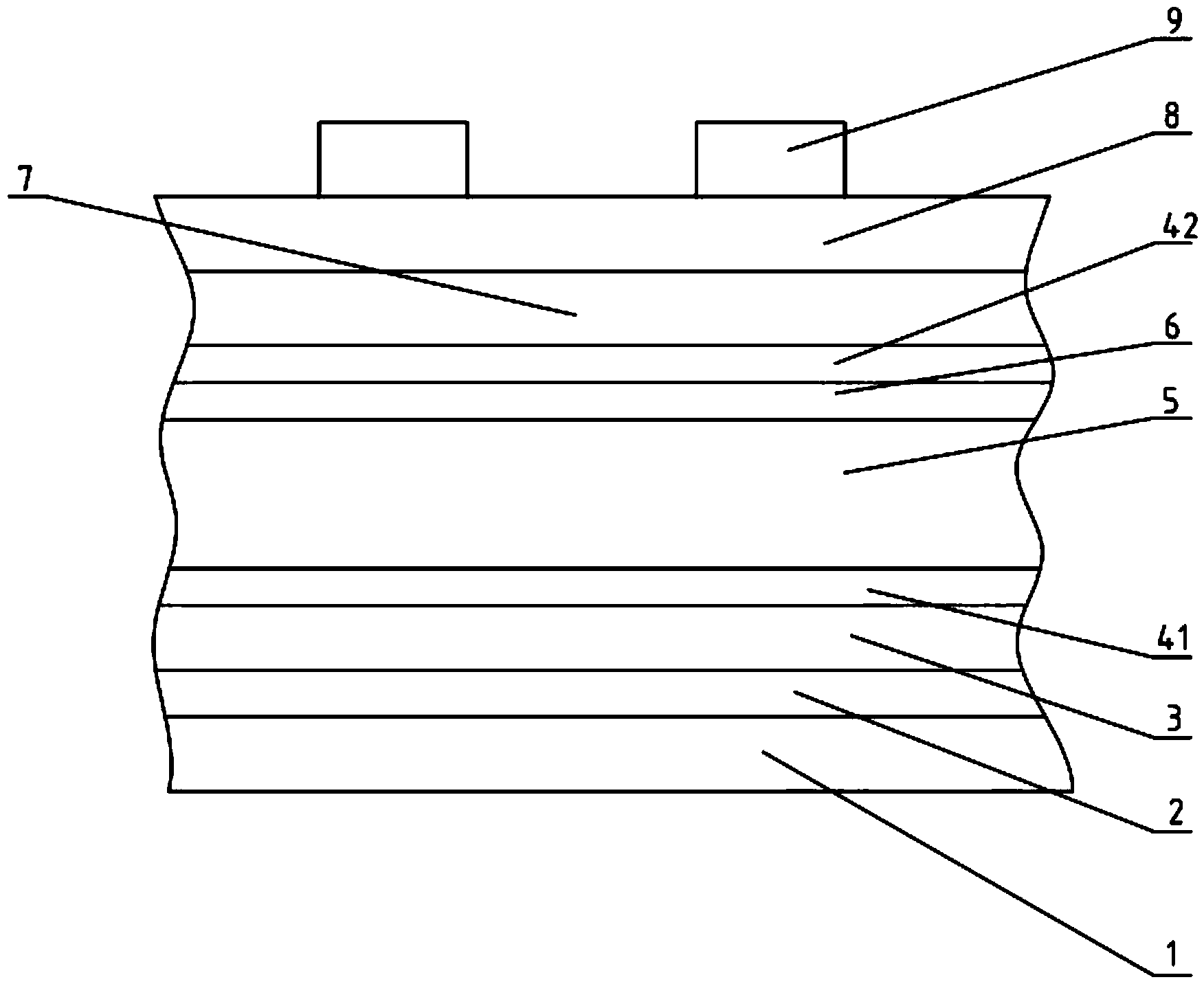

[0021] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

[0022] A preparation process for a heterojunction solar cell, the steps of which are as follows:

[0023] 1) A crystalline silicon wafer is used as the crystalline silicon substrate 5, and its surface is cleaned; the thickness of the crystalline silicon wafer is 200 μm, and the resistivity is 2-5 Ω·cm; the cleaning can be conventional RCA cleaning.

[0024] 2) Next, the front surface of the crystalline silicon substrate 5 is treated with the interface treatment method of the heterojunction solar cell to prepare the heavily doped layer 6; the interface treatment method of the heterojunction solar cell is: in the heterojunction solar cell In the preparation process, the front surface of the crystalline silicon wafer is highly doped by ion implantatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com