Composite getter device for vacuum insulated panel and method for manufacturing composite getter device

A technology of vacuum insulation panels and air suction devices, which is applied in heat exchange equipment, mechanical equipment, and pipelines through heat insulation protection, can solve the problems of difficult process costs, etc., to ensure effectiveness, improve air suction efficiency, and improve water absorption effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

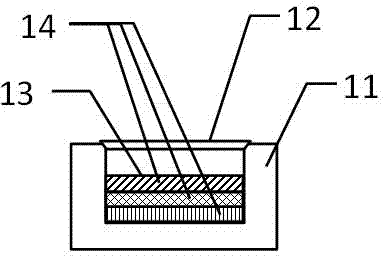

[0026] Embodiment 1: as figure 1 , using a mold to press high-temperature activated zirconium-cobalt alloy powder, barium-lithium alloy powder, and calcium oxide powder into three sheet-shaped suction units 14, and stack them in sequence to form the central layer 13. Put the central layer into the plastic shell 11, adjust the air pressure to 90kPa, plug the opening of the shell with a plastic sealing plug 12, and obtain the final composite suction device for vacuum insulation panels. Use a mold to press a groove with a suitable size and height on the core material of the vacuum insulation panel, and put the composite getter horizontally into the groove. The core material and the composite getter are packed into a composite barrier film bag, and vacuum-packed to obtain a vacuum insulation panel.

[0027] Wherein, the zirconium-cobalt alloy powder is made by the following method, weighing 83.6g of zirconium and 9.9g of cobalt and 6.5g of rare earth metal mixture, and the weight...

Embodiment 2

[0028] Embodiment 2: as figure 1 , respectively pressing high-temperature-activated titanium-vanadium-iron alloy powder, barium-sodium alloy powder, and sodium oxide powder into three sheet-shaped suction units 14 with a mold, and stacking them in sequence to form the central layer 13 . Put the central layer into the aluminum shell 11, adjust the air pressure to 50kPa, plug the opening of the shell with a rubber sealing plug 12, and obtain the final composite suction device for vacuum insulation panels. Use a mold to punch a hole of a suitable size on the core material of the vacuum insulation panel, and put the composite getter horizontally into the hole. The core material and the composite getter are packed into a composite barrier film bag, and vacuum-packed to obtain a vacuum insulation panel.

[0029] Wherein, the ferro-titanium vanadium alloy powder is prepared by the following method:

[0030] (1) Mix the above three metal powders in a weight ratio of 5:3:2 and mix ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com