A kind of binder used in foam phenolic color steel composite material

A composite material and adhesive technology, applied in the direction of adhesives, etc., to achieve the effect of preventing powder drop, high bonding strength and good film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

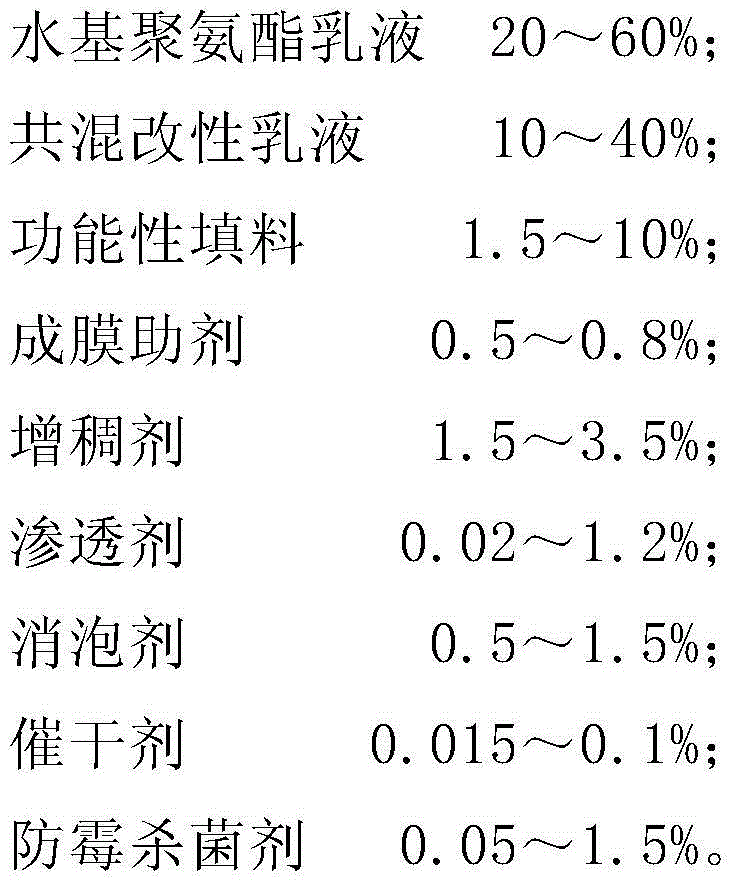

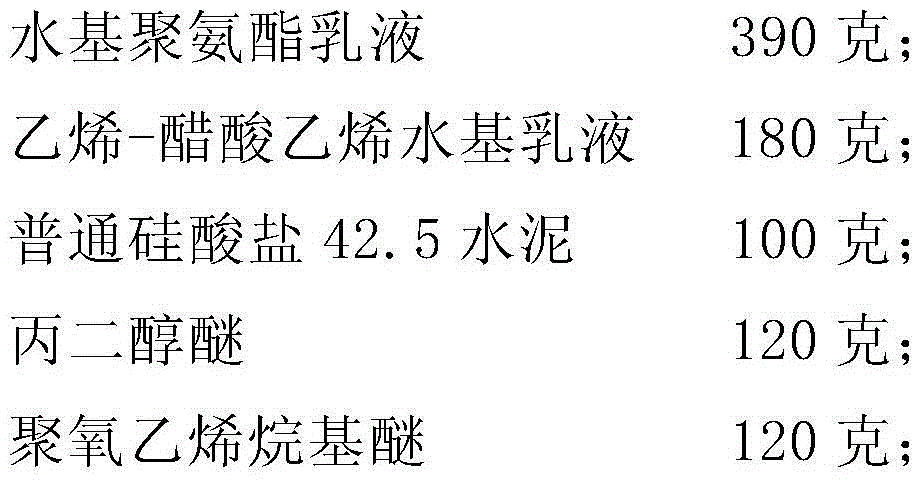

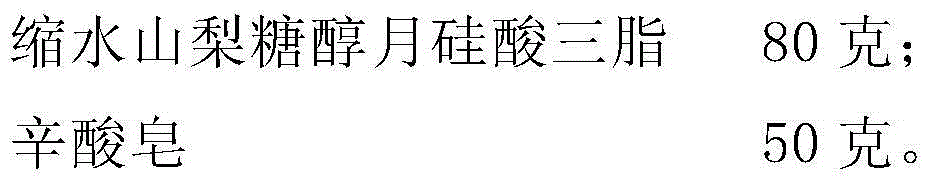

[0025] A binder used for foamed phenolic color steel composite materials, the specific formula of the binder for preparing 1000 grams is as follows:

[0026]

[0027]

[0028] making process:

[0029] Under low-speed stirring, add metered water-based polyurethane emulsion and ethylene-vinyl acetate water-based emulsion and stir evenly; under low-speed stirring, add metered propylene glycol ether, polyoxyethylene alkyl ether, sorbitan lauric acid triglyceride, and caprylic acid soap in turn. Stir well; under low speed stirring, add the metered ordinary silicate 42.5 cement and stir well.

[0030] This adhesive is suitable for the double-sided coating of foamed phenolic in the foamed phenolic / color steel composite material.

Embodiment 2

[0032] A binder used for foamed phenolic color steel composite materials, the specific formula of the binder for preparing 1000 grams is as follows:

[0033]

[0034] making process:

[0035] Under low-speed stirring, add metered water-based polyurethane emulsion and acrylic water-based emulsion and stir evenly; under low-speed stirring, add metered 2.2.4-trimethylpentanediol-1.3 monoisobutyrate, acetylene glycol, polypropylene glycol in turn , naphthenic acid soap, and 8-hydroxyquinoline, and stir evenly; under low-speed stirring, add metered borax and organic bentonite and stir evenly.

[0036] This adhesive is suitable for the adhesive of the color steel plate and the coated foamed phenolic board in the foamed phenolic / color steel composite material.

Embodiment 3

[0038] A binder used for foamed phenolic color steel composite materials, the specific formula of the binder for preparing 1000 grams is as follows:

[0039]

[0040] making process:

[0041] Under low-speed stirring, add metered water-based polyurethane emulsion, acrylic water-based emulsion, and ethylene-vinyl acetate water-based emulsion and stir evenly; under low-speed stirring, add metered propylene glycol phenyl ether, 10% butyl acetate cellulose, and polyoxyethylene alkyl in turn. Ether, naphthenic acid soap, and 2-(4-thiazolylhydroxy)benzimidazole are stirred evenly, and under low-speed stirring, add the metered fly ash and stir evenly.

[0042] This binder is suitable for the binder of inorganic boards (silicon calcium board, gypsum board, fiber reinforced cement board) and coated foam phenolic board in foamed phenolic / color steel composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com