Silicon-based modified fadable pigment and preparation method thereof

A fading pigment and silicon-based technology, applied in the field of silicon-based modified fading pigments and their preparation, can solve the problems of fading and unfavorable paper recycling, and achieve the effects of good tinting strength, energy saving and good physiological compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

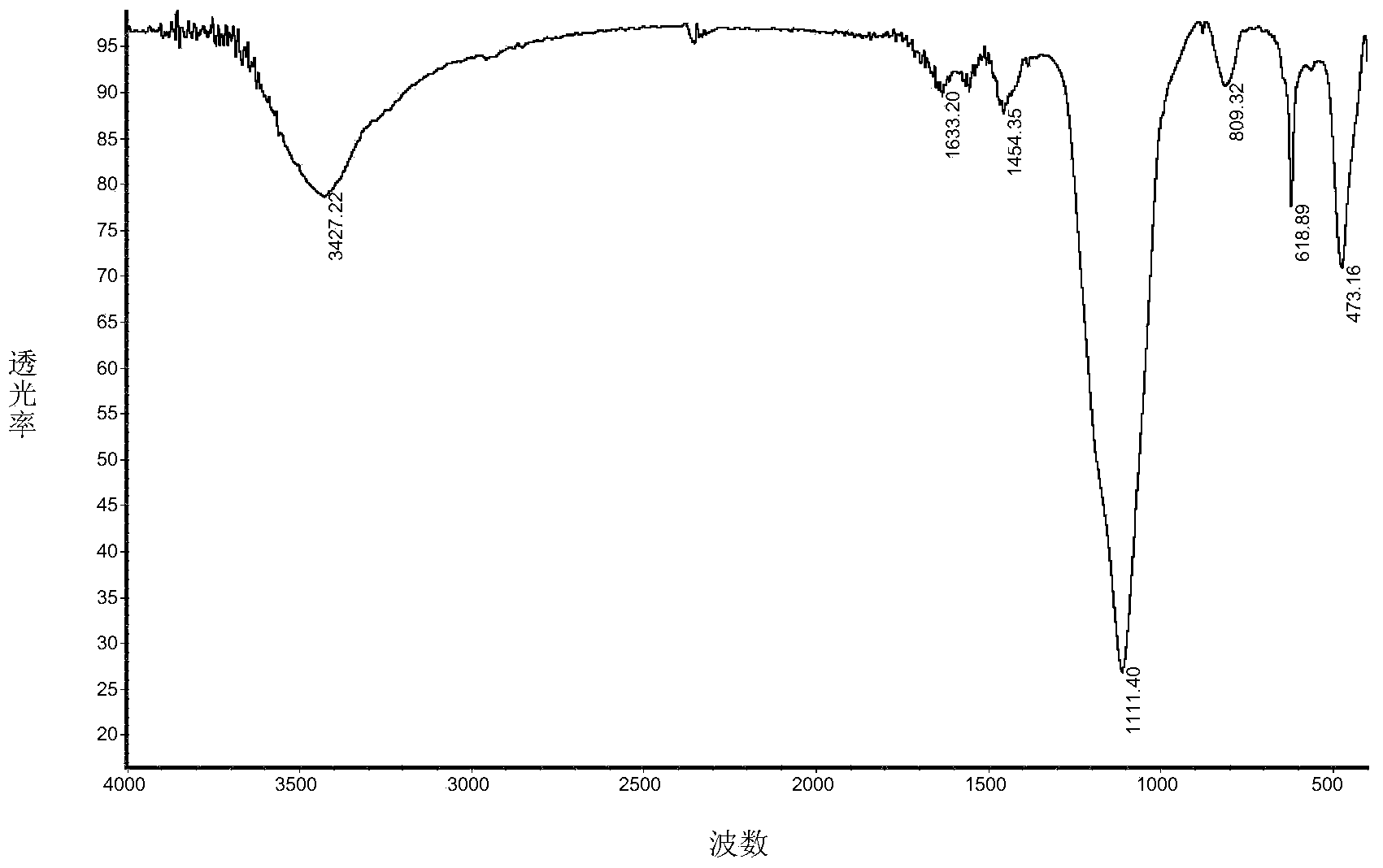

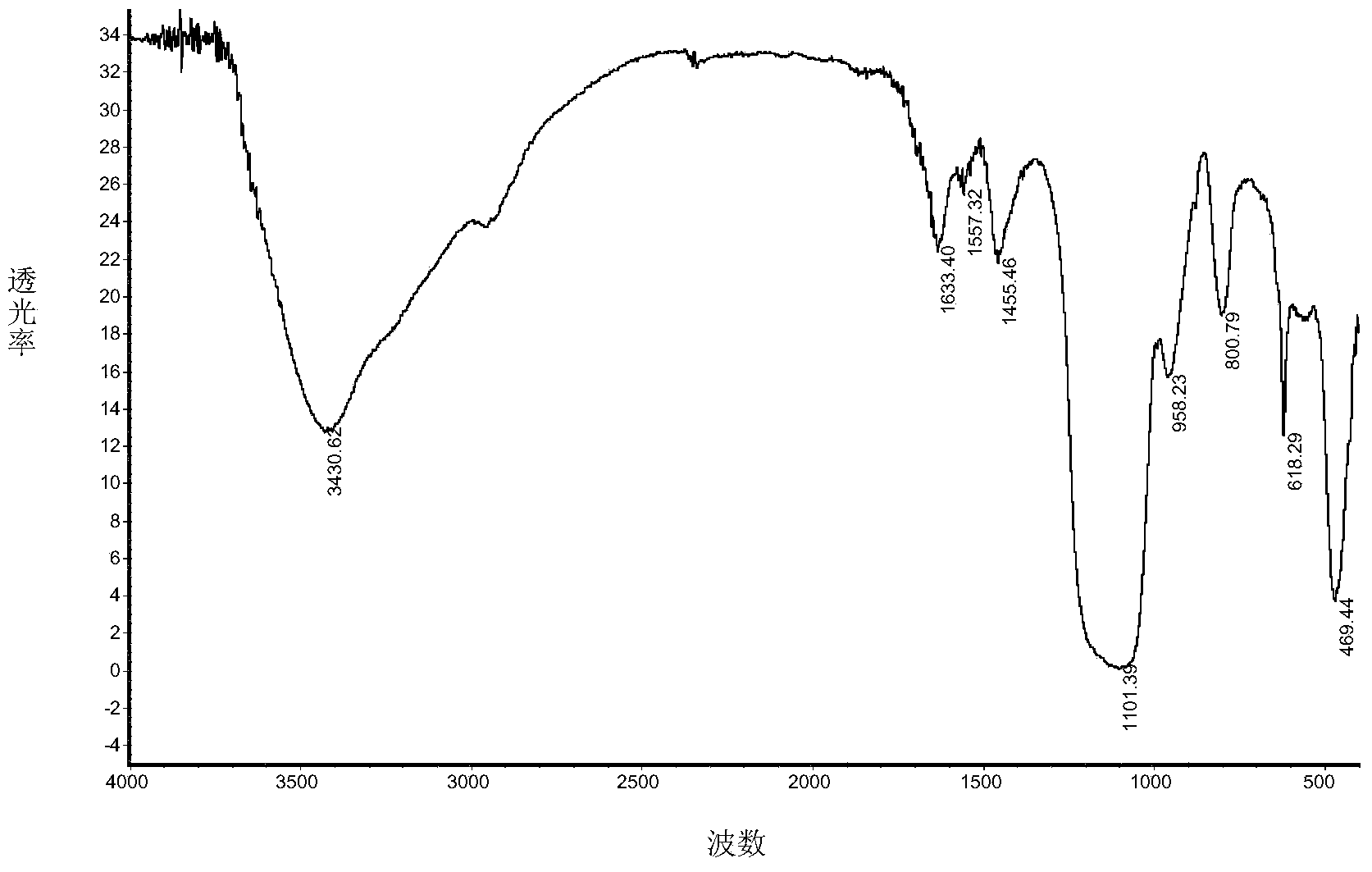

[0027] (1) Preparation of amino-modified silica: disperse 1 g of silica with a particle size of 50-300 nm (see figure 1 , Figure 7 ) into 93mL absolute ethanol to obtain a bluish transparent liquid. Add 0.7mL γ-aminopropyltriethoxysilane, stir at room temperature for 5h, then centrifuge at high speed (12000rpm, 30min), wash with ethanol, acetone, tetrahydrofuran twice (12000rpm, 15min) in order to remove Unreacted γ-aminopropyltriethoxysilane and polycondensate to obtain amino-modified silica (see figure 2 ).

[0028] figure 1 Medium, 3427cm -1 Left and right are SiO 2 Stretching vibration region of surface adsorbed hydroxyl group, 1630cm -1 There are weak carbonyl stretching vibrations on the left and right, which may be due to the dispersion of silica with a carboxyl-containing dispersant.

[0029] figure 2 , C-N stretching vibration at 958cm -1 The shoulder peak at corresponds to the deformation vibration absorption peak of the amino group.

[0030] (2) Prepara...

Embodiment 2

[0034] Weigh 0.1 g of carboxy-modified silica, the product of step (2) in Example 1, and put it into 10 mL of dichloromethane, then add 3 mL of ethanol and 0.1 g of HATU, and disperse evenly at room temperature, then add 0.2 g of acid fuchsin, and Reaction 20h. The product was vacuum-dried at 110°C for 8 hours to obtain a red silicon-based modified fadeable pigment (see Figure 5 , Figure 9 ).

[0035] The pigment is bright red and does not fade when washed with water. After adding 5% formamidine sulfinic acid solution, the red color will completely fade within 10 minutes.

Embodiment 3

[0037] Weigh 0.1 g of carboxy-modified silica, the product of step (2) in Example 1, and put it into 10 mL of dichloromethane, then add 2 mL of ethanol and 0.1 g of HATU, after uniform dispersion at room temperature, add 0.3 g of acid green, and react at room temperature 25h. The product was vacuum-dried at 110°C for 7 hours to obtain a green silicon-based modified fadeable pigment (see Figure 6 , Figure 10 ).

[0038] The bright color of the pigment does not fade when washed with water, and the green color completely fades within 4 minutes after adding 3% sodium sulfite solution.

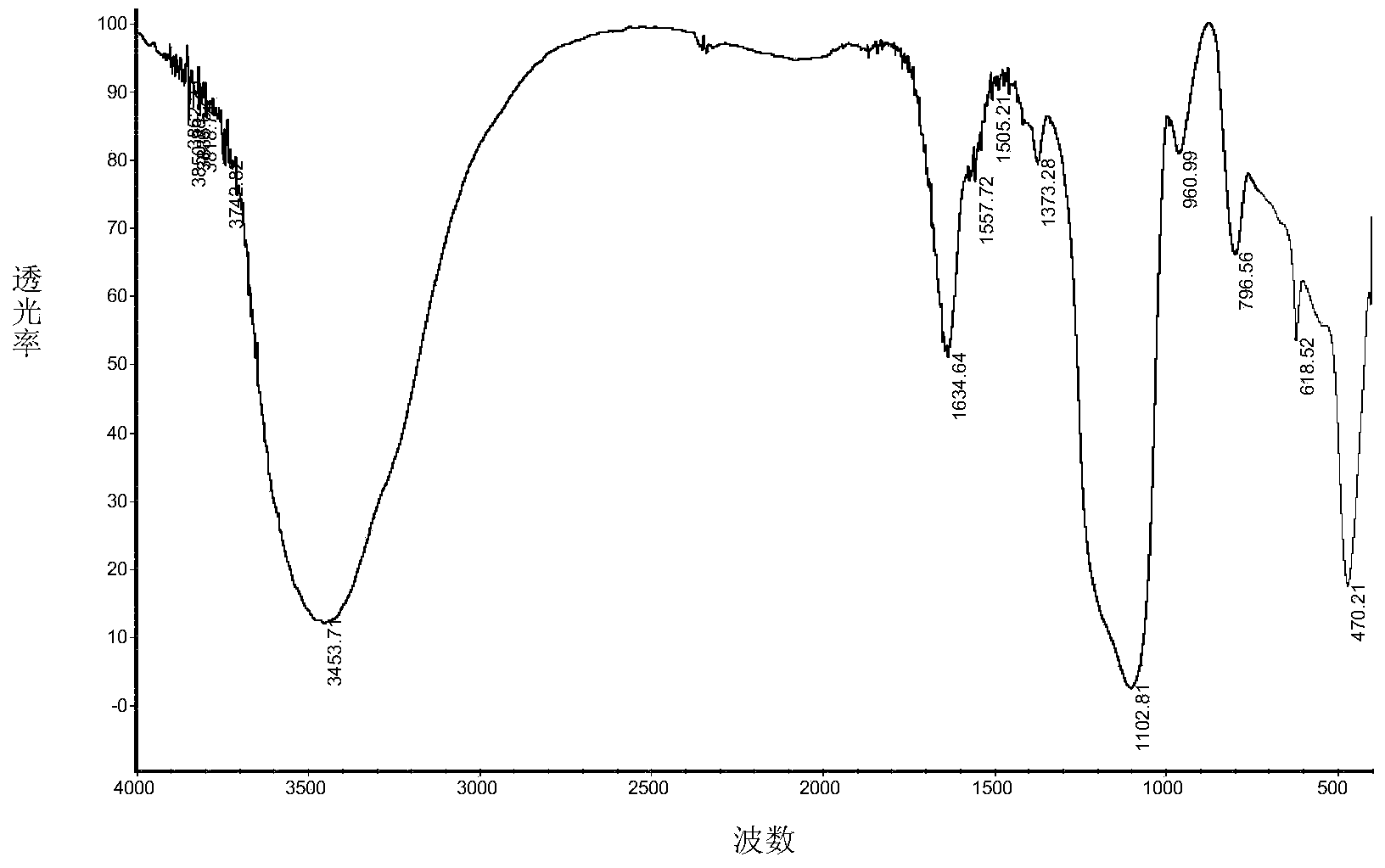

[0039] The above red, green and blue dyes have similar molecular structures and are all bonded to the same substrate through amide bonds, so their spectra are similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com