Method for determining the content of harmful elements in iron ore by using X-ray fluorescent spectrometry

A technique of fluorescence spectroscopy and harmful elements, applied in measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve the problem of not being able to know and master the real-time furnace conditions, composition and crystal form differences of ironmaking blast furnaces in time, Problems such as the inability to measure multiple elements at the same time achieve the effects of overcoming particle size effects and mineral effects, reducing absorption-enhancement effects, and shortening the detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] (2) Preparation of samples and calibration samples:

[0019] Use anhydrous lithium tetraborate as the flux, sodium nitrate as the oxidant, and ammonium bromide as the release agent. The dilution ratio of the sample and the flux is 1:16; accurately weigh the sample and the flux in a weighing dish, and add a certain amount After fully mixing, transfer the oxidant into a platinum-yellow crucible, and add a certain amount of release agent; put it into a melting machine, and melt it at 1150°C for 15 minutes to make a glass sample. After demoulding and cooling, put it in a desiccator for testing.

[0020] (3) Calibration curve creation:

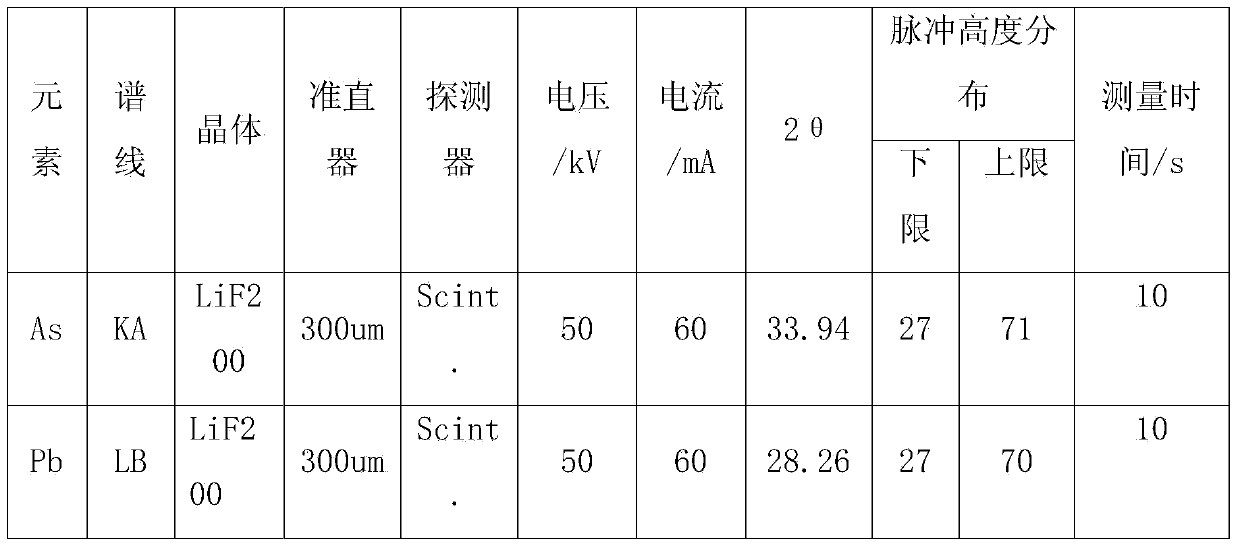

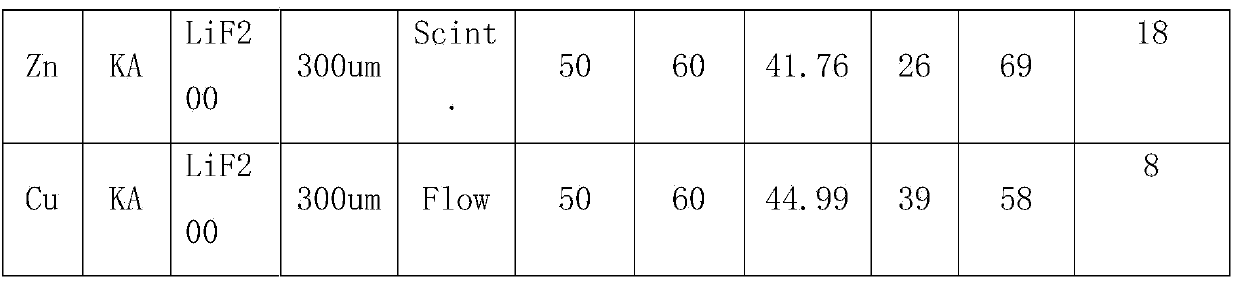

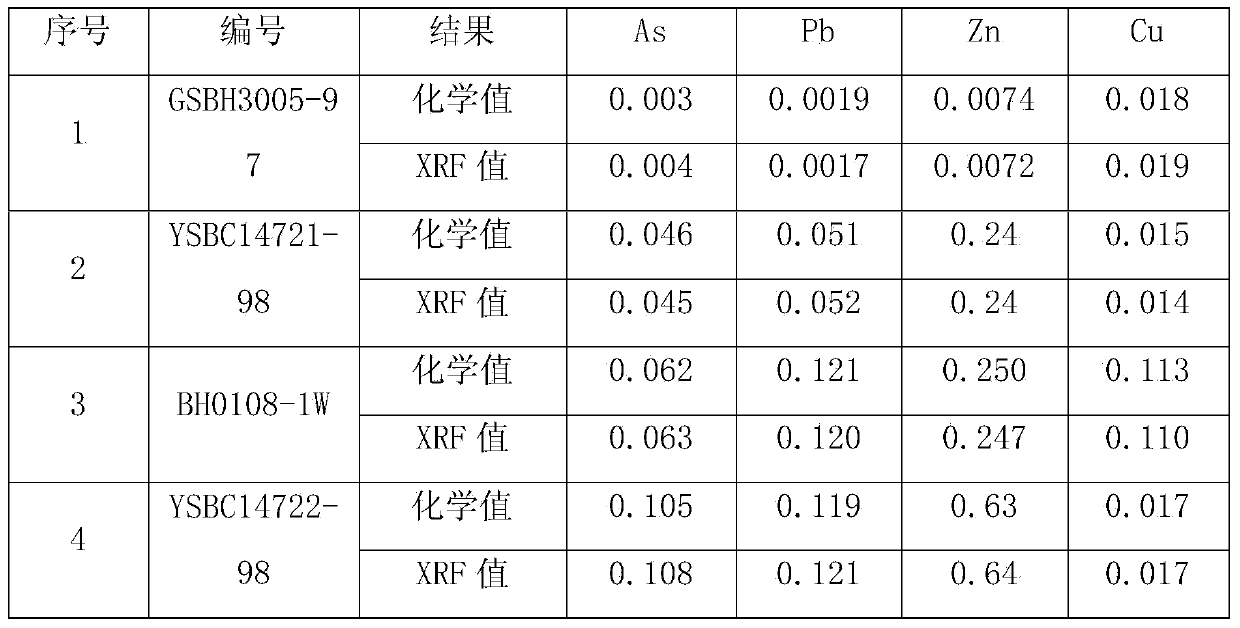

[0021] Use the series of calibration samples prepared in Table 1 to prepare glass samples according to step (2), and carry out the condition test on the X-ray fluorescence spectrometer, select the appropriate crystal, collimator, voltage and current, 2θ and pulse height distribution, etc., to obtain Choose the best analytical conditions fo...

Embodiment 1

[0024] Embodiment 1, a method for determining the content of harmful elements As, Pb, Zn and Cu in iron ore by X-ray fluorescence spectrometry: the first step, the selection of calibration samples:

[0025] Select 7 iron ore standard samples, add reference substances with the iron ore standard samples, prepare 5 synthetic standard samples with a certain gradient according to a certain proportion, and form a series of calibration samples. The series of calibration samples are shown in Table 1 below, and the content distribution of each element is shown in Table 2 below.

[0026] Table 1 Calibration sample series

[0027] serial number

serial number

sample name

1

GSBD31004-93

iron ore

2

GSBH30002-97

iron ore

3

GSBH30003-97

iron ore

4

GSBH30005-97

iron ore

5

GSBH30006-97

iron ore

6

YSBC14721-98

7

YSBC14722-98

8

HC-1

Synthet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com