A kind of chitosan nanofibrous membrane for dura mater or dura mater repair and its preparation method and application

A technology of chitosan and fiber membranes, applied in spinning solution preparation, fiber chemical characteristics, textiles and papermaking, etc. Carry out clinical promotion and other issues to achieve the effect of easy control of product quality, good application prospects, simple preparation process and product composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

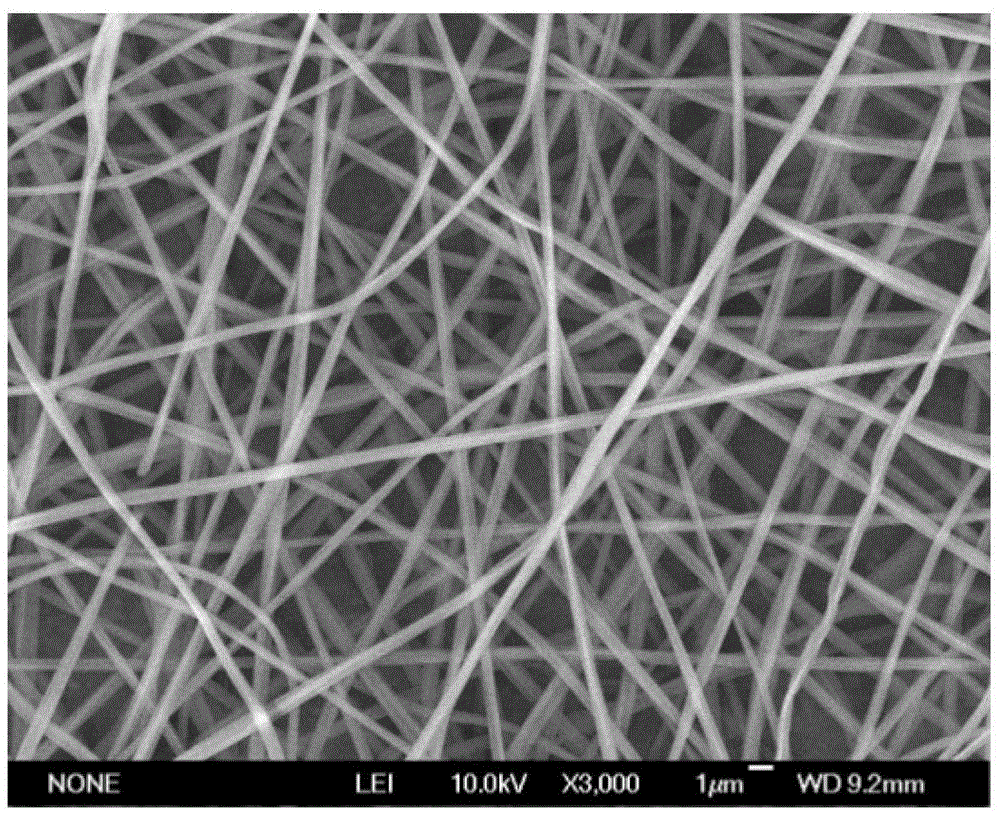

[0059] Embodiment 1: Preparation of chitosan dura mater repair material

[0060] (1) Wash the fresh shrimp shells with heads and tails removed, soak them in 5% HCl and 10% NaOH for 12 hours, wash until neutral, dry and grind them, and place the obtained powder at 100°C React in 50% NaOH solution for 24 hours, then wash until neutral, dehydrate with alcohol, and finally vacuum dry to obtain chitosan with a deacetylation degree of 85-95%.

[0061] (2) Dissolve 0.125 g of chitosan in 10 ml of a mixed solution of hexafluoroisopropanol and acetic acid (2% volume fraction of acetic acid), and stir overnight at room temperature to form a stable solution.

[0062] (3) Put the chitosan solution into the syringe, and connect the needle of the syringe to a high-voltage power supply. The solution supply flow was controlled at 5ml / h by a microflow pump, the applied voltage was 15kv, the distance between the high voltage end and the ground end was 15cm, and the rotation speed of the drum u...

Embodiment 2

[0064] Example 2: Research on the Mechanical Properties of Chitosan Nanofiber Membrane Materials

[0065] Cut the chitosan fiber membrane into a sample with a length and width of 40×4mm, and trim the two sides of the sample flat to prevent cracks, then use a spiral micrometer to measure the thickness of each sample, and select different parts for three measurements to get the average value. Then, the tensile mechanical properties were measured by a universal mechanical testing machine, and the rising speed of the crosshead was 2mm / min. The average value of five parallel samples was taken for each test result.

[0066] The tensile strength of the chitosan fiber membrane is 7.93±0.35MPa, and the elastic modulus is 117.9±7.6MPa. figure 2 shown. Much higher than the mechanical properties of nanofiber membranes such as polylactic acid, polycaprolactone and collagen reported in the literature, such as polylactic acid fiber membrane tensile strength is 3.59MPa (ParkWHet.al., Ther...

Embodiment 3

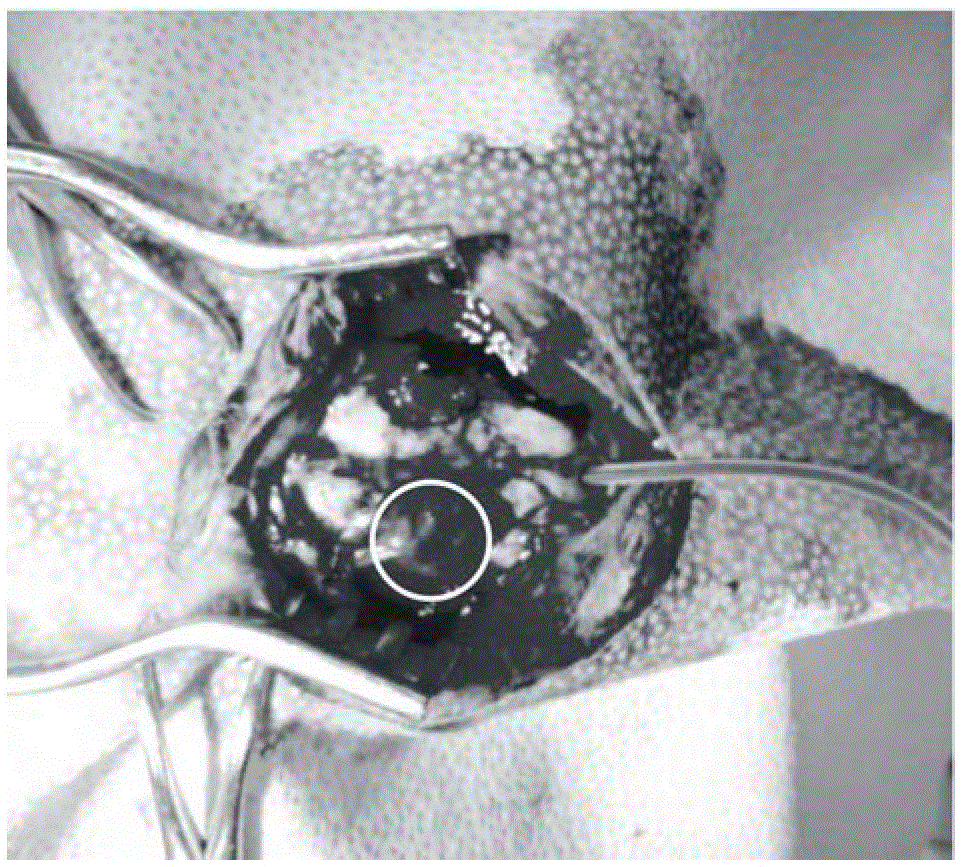

[0067] Example 3: Research on Biocompatibility and Degradability of Chitosan Nanofiber Membrane

[0068] Rabbits were selected as experimental animals, chitosan fiber membranes were embedded in the leg muscles of the rabbits, and the animals were sacrificed 6 weeks after the operation, and the injected muscles were fixed in 10% formalin for gross observation and HE staining Observe and evaluate its biocompatibility.

[0069] The results showed that after 6 weeks, the chitosan nanofiber membrane was completely wrapped by the envelope, and had been significantly degraded, softened into a gel, and had no adhesion with the envelope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com