Engineered bacterium for producing tobramycin by direct fermentation and construction and application of engineered bacterium

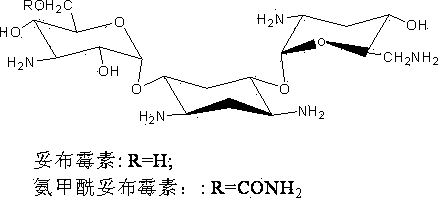

A technology of tobramycin and carbamycin tobramycin is applied in the field of direct fermentation to produce tobramycin engineering bacteria and its construction and application, which can solve the problems of no obvious breakthrough and the like, so as to reduce production costs and improve products. Quality, effect of solving technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

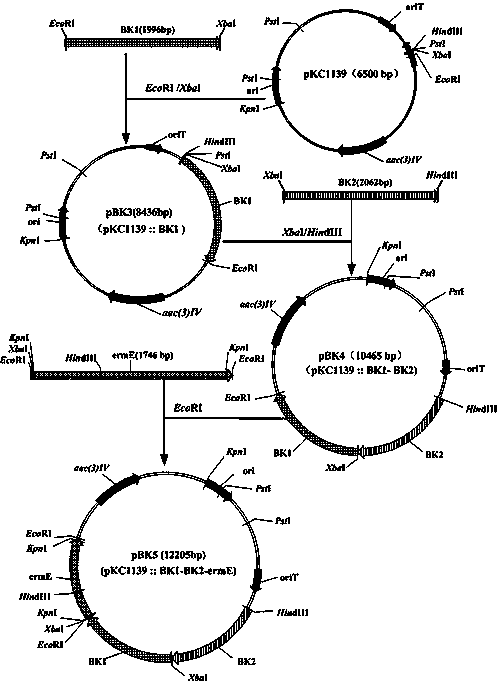

[0031] Embodiment 1: Construction of recombinant plasmid pBK5

[0032] by S . tenebrarius Tt-49 chromosomal DNA is used as a template, and primers PK1 / PK2 are used to amplify the 1984bp upstream exchange arm BK1, which includes wxya Partial sequence and its upstream fragment, for PCR products EcoR I and Xba Digested with I, connected to the pKC1139 vector digested with the same enzyme to obtain intermediate plasmid pBK3. Then using Tt-49 chromosomal DNA as a template, primers PK3 / PK4 are used to amplify the 2050bp downstream exchange arm BK2, which includes wxya Partial sequence and its downstream fragments, PCR products were Xba I with Hin After digestion with dIII, it was connected to pBK3 digested with the same enzyme to obtain intermediate plasmid pBK4. last use EcoR I Digest the plasmid pAGe containing the erythromycin resistance gene, recover the 1746bp fragment and insert it into the EcoR I digested and dephosphorylated pBK4 to obtain recombinant pla...

Embodiment 2

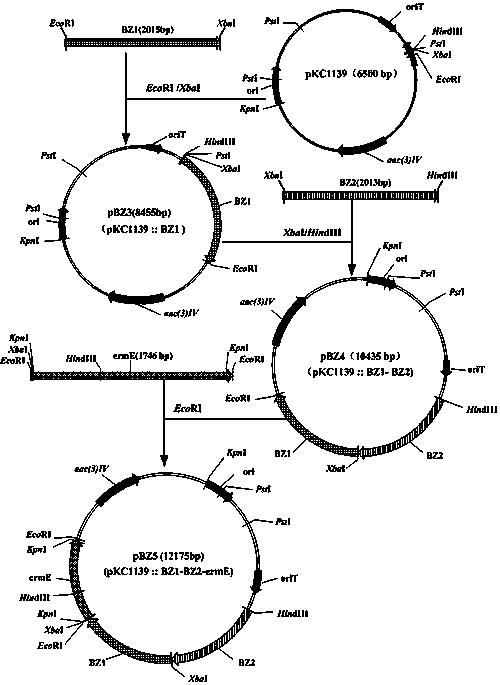

[0038] Embodiment 2: transformation of recombinant plasmid pBK5 S. tenebrarius Tt-49

[0039] Transform the recombinant plasmid pBZ5 E. coli ET12567 (pUZ8002), the donor bacteria containing the recombinant plasmid E. coli ET12567 (pUZ8002, pBK5), after overnight culture, transferred to 30ml LB medium supplemented with corresponding antibiotics (kanamycin 25μg / ml, chloramphenicol 25μg / ml, apramycin 50μg / ml), cultured 2- After 3 h, the cells entered the logarithmic growth phase, collected by centrifugation at 8000 rpm for 5 min, washed twice with an equal volume of fresh LB to remove residual antibiotics, and suspended in an appropriate amount of LB medium for later use. At the same time, scrape the right amount of mature and plump S . tenebrarius Tt-49 slant spores were suspended in 2×YT medium, heat-shocked at 50°C for 10 min, and cooled to room temperature. Mix the spore suspension and Escherichia coli suspension in equal proportions, smear them on MS plates afte...

Embodiment 3

[0040] Example 3 : wxya Screening and validation of blocking mutants

[0041] Transfer the single-crossover mutant strain to the slant medium, isolate a single colony after 5 generations of relaxation culture, and copy it to the resistance plate added with erythromycin and the ordinary plate without antibiotics. After culturing, 7 strains were screened and grown on the ordinary plate The erythromycin-sensitive type (Ery S ) strains. These Ery S strains may be wxya Blocking mutant strains, and possibly reverting mutant strains, for the final screening wxya The blocking mutant strains were screened and verified by PCR method.

[0042] Randomly pick 3 plants of Ery S The strains are numbered K1, K2, K3 respectively. Chromosomal DNA was extracted and identified by PCR using primers P5 / P6. According to the homologous recombination model, wxya A fragment of about 1022bp can be amplified from the blocking mutant strain, and a fragment of about 1415bp can be amplified f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com