Halogen-free low water-absorbent thermosetting flame retardant resin composition and application thereof

A technology of flame retardant resin and low water absorption, which is applied in the field of preparing adhesive sheets and copper clad laminates with halogen-free low water absorption thermosetting flame retardant resin composition, which can solve the problems of insufficient heat resistance of immersion tin, poor heat resistance of immersion tin, and poor processability Good and other problems, to achieve high heat resistance, good thermal stability, increase the effect of crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

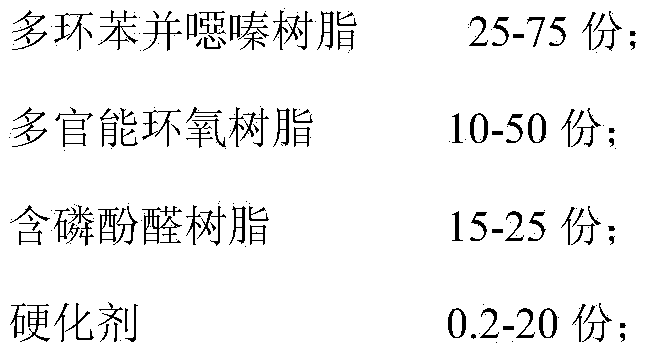

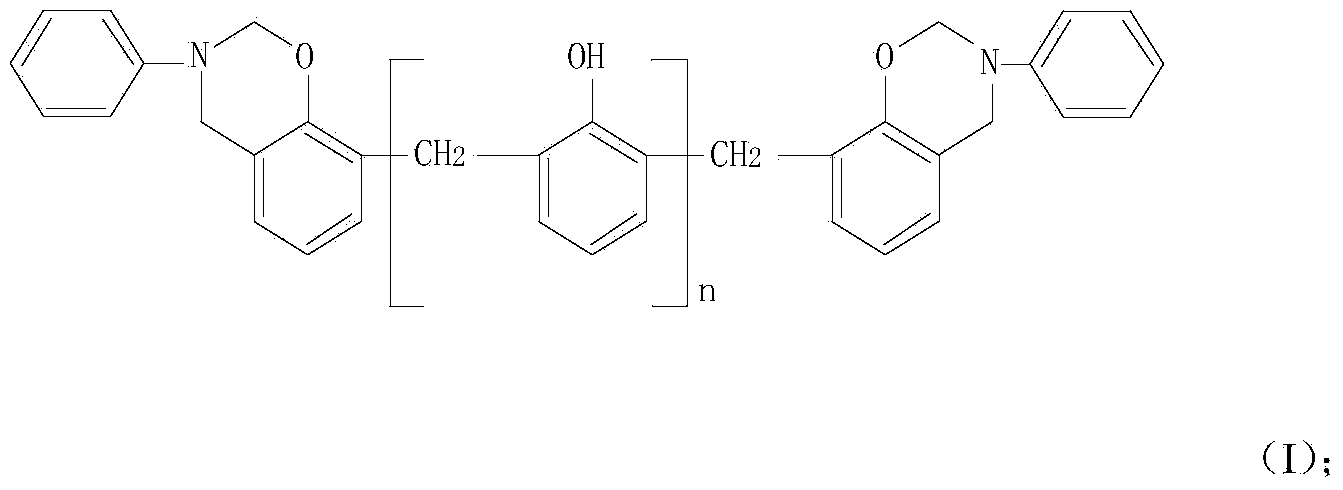

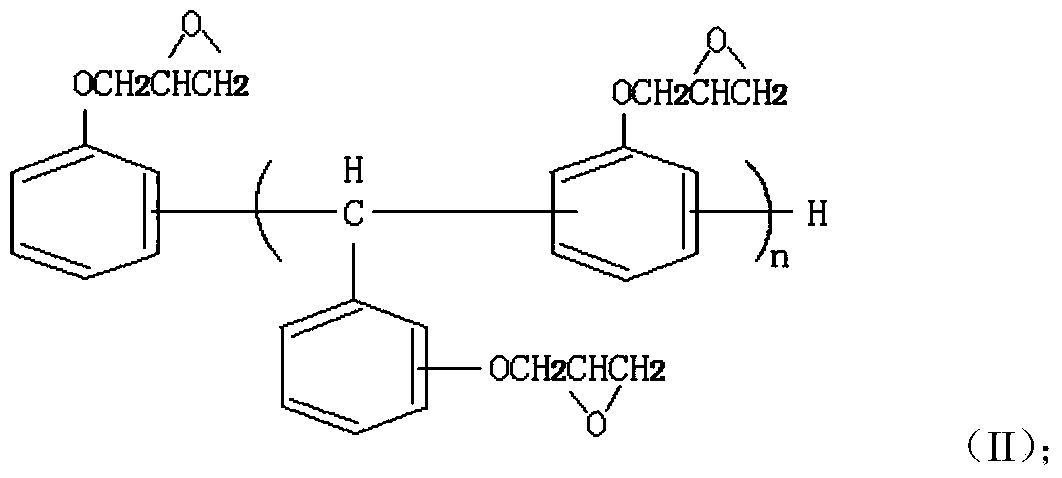

[0056] The halogen-free low water absorption thermosetting flame retardant resin composition comprises:

[0057] Polycyclic benzoxazine resin, as shown in formula (I), n is 2;

[0058] Trifunctional epoxy resin, as shown in formula (II),

[0059] Phosphorus-containing phenolic resin is shown in formula (IV),

[0060] The hardener is a mixture of phenol novolak resin and accelerator 2-methylimidazole;

[0061] The inorganic filler is a mixture of talcum powder and aluminum hydroxide in a weight ratio of 1:1.

Embodiment 2

[0063] The halogen-free low water absorption thermosetting flame retardant resin composition comprises:

[0064] Polycyclic benzoxazine resin, as shown in formula (I), n is 3;

[0065] Trifunctional epoxy resin, as shown in formula (II), n is 2;

[0066] Phosphorus-containing phenolic resin is shown in formula (IV), n is 2;

[0067] The hardener is a mixture of o-formaldehyde phenolic resin and accelerator 2-methylimidazole;

[0068] The inorganic filler is aluminum hydroxide.

Embodiment 3

[0070] The halogen-free low water absorption thermosetting flame retardant resin composition comprises:

[0071] Polycyclic benzoxazine resin, as shown in formula (I), n is 4;

[0072] Trifunctional epoxy resin, as shown in formula (II), n is 3;

[0073] Phosphorus-containing phenolic resin is shown in formula (IV), n is 3;

[0074] The hardener is a mixture of bisphenol A novolak resin and accelerator 2-ethyl-4-methylimidazole;

[0075] The inorganic filler is silica powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com