Preparation method of organic single-layer graphene solution

A single-layer graphene, organic solution technology, applied in the field of graphene, can solve the problems of high price, inability to meet diversified industrial uses, and the aqueous solution does not have the characteristics of other organic compounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

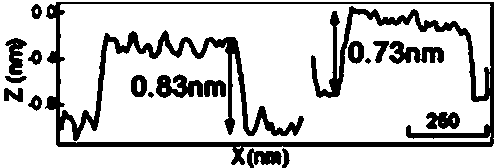

Image

Examples

Embodiment 1

[0031] A method for preparing a monolayer graphene organic solution, carried out according to the following steps:

[0032] (1) Prepare 100ml of a solution consisting of dodecyltriphenylphosphine bromide and N-methylpyrrolidone at a ratio of 1:2, soak 1g of 400 mesh natural graphite powder into the solution at -5°C , fully stirred for 30 minutes, and under the action of a working frequency of 45 kHz and a power of 160 W, ultrasonication was performed for 50 minutes to intercalate solvent molecules into the graphite molecules to obtain expandable graphite.

[0033] (2) In an argon-protected environment, heat to 80°C and hold for 20 minutes to obtain expanded graphite.

[0034] (3) Under the action of a working frequency of 60kHZ and a power of 160W, the expanded graphite solution was ultrasonically peeled off for 50 minutes to obtain a black single-layer graphene solution.

[0035] (4) Suction filter the graphene solution, wash the filter cake twice with 2% dilute hydrochloric...

Embodiment 2

[0038] A method for preparing a monolayer graphene organic solution, carried out according to the following steps:

[0039] (1) Prepare 100ml of a solution consisting of dodecyltriphenylphosphine bromide and N-methylpyrrolidone at a ratio of 2:1, and soak 5g of 600 mesh natural graphite powder into the solution at -8°C , fully stirred for 70min, and under the action of 45kHz working frequency and 160W power, ultrasonication for 2h made solvent molecules intercalate between graphite molecules to obtain expandable graphite.

[0040] (2) Under an argon protection environment, heat to 100°C and hold for 50 minutes to obtain expanded graphite.

[0041] (3) Under the action of a working frequency of 60kHZ and a power of 160W, the expanded graphite solution was ultrasonically peeled off for 2 hours to obtain a black single-layer graphene solution.

[0042] (4) Suction filter the graphene solution, wash the filter cake with 2% dilute hydrochloric acid for 5 times, wash with deionized...

Embodiment 3

[0045] A method for preparing a monolayer graphene organic solution, carried out according to the following steps:

[0046] (1) Take 100ml of dodecyltriphenylphosphine bromide solution, soak 3g of 800 mesh natural graphite powder into the solution in the environment of -10℃, stir for 60min, under the action of working frequency 45kHz and power 160W, Ultrasound for 1 h makes solvent molecules intercalate between graphite molecules to obtain expandable graphite.

[0047] (2) Under an argon protection environment, heat to 90°C and hold for 1 hour to obtain expanded graphite.

[0048] (3) Under the action of a working frequency of 60kHZ and a power of 160W, the expanded graphite solution was ultrasonically peeled off for 90 minutes to obtain a black single-layer graphene solution.

[0049](4) Suction filter the graphene solution, wash the filter cake three times with 2% dilute hydrochloric acid, wash with deionized water until neutral, and dry in an oven at 60°C for 7 hours to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com