Solid acid catalyst and preparation method thereof, and preparation method of diolefin compound

A solid acid catalyst and catalyst technology, applied in the direction of catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problems of difficult industrial production and low selectivity of isoprene, and achieve low toxicity and high yield Effects of selectivity and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

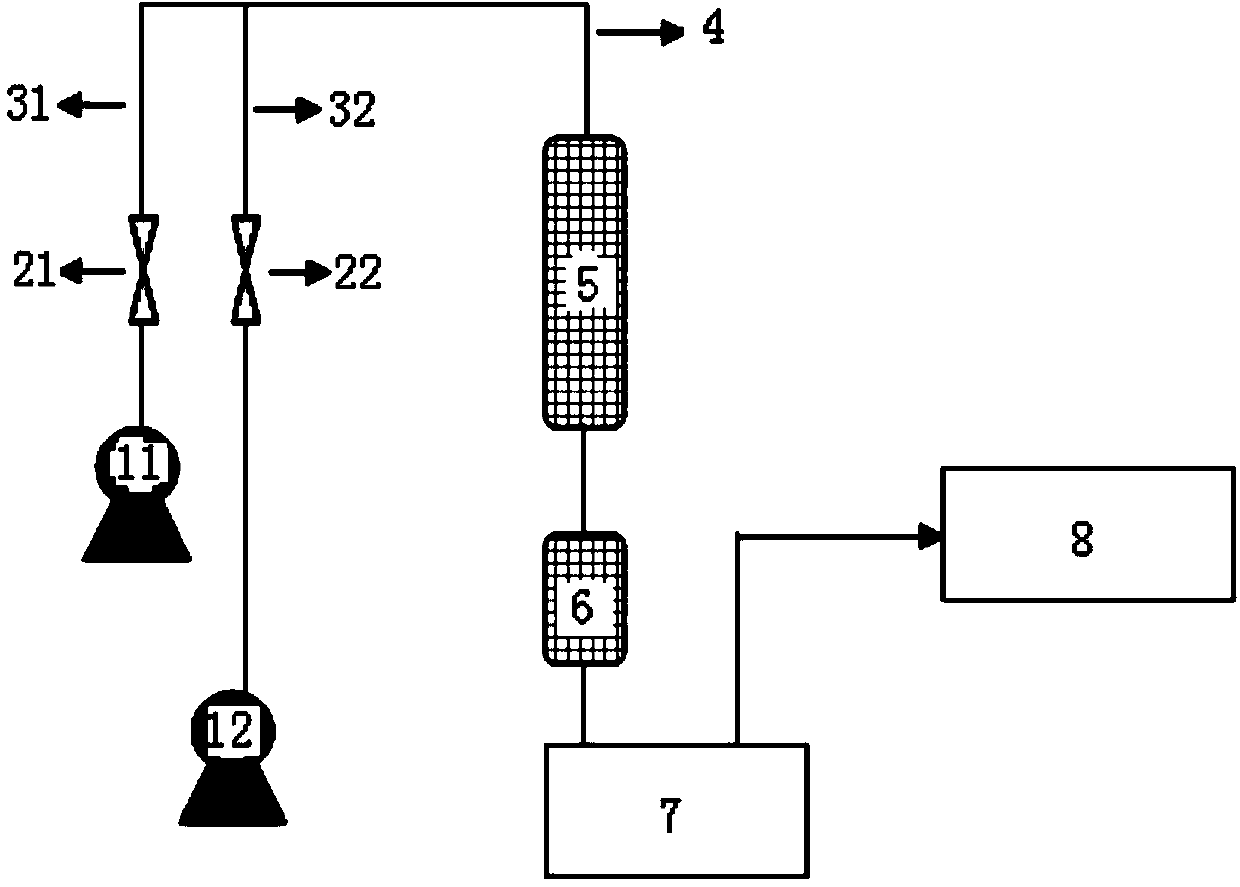

Method used

Image

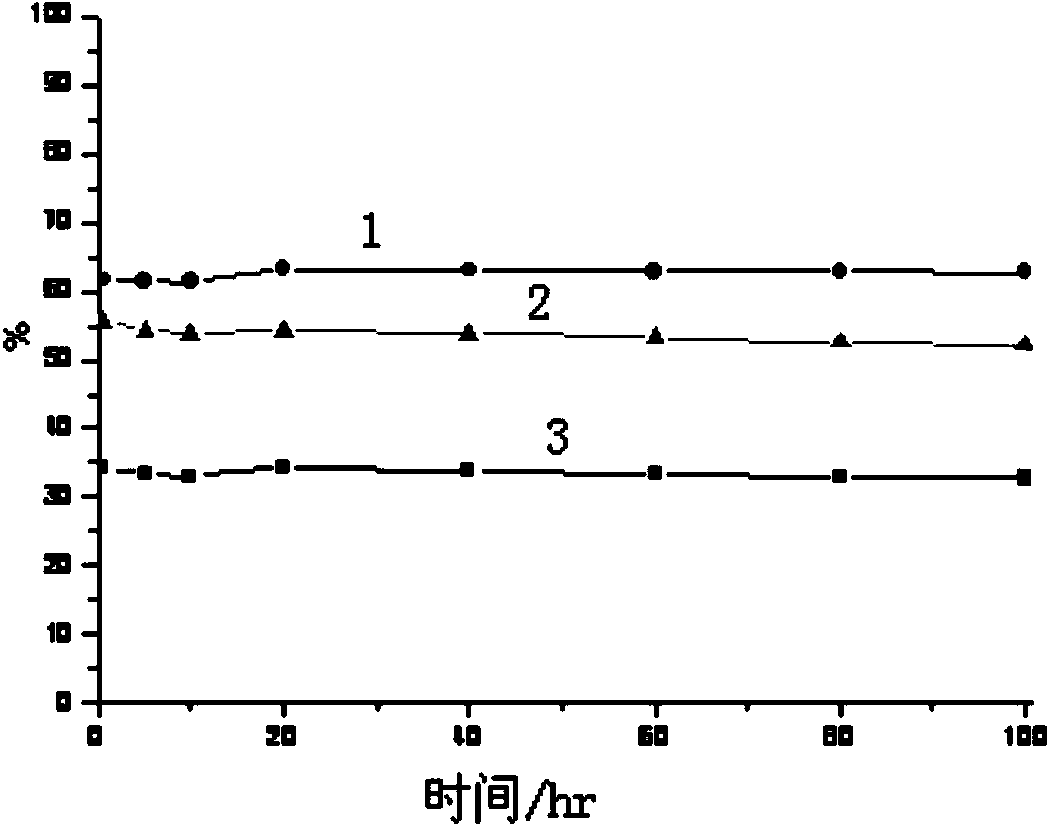

Examples

preparation example Construction

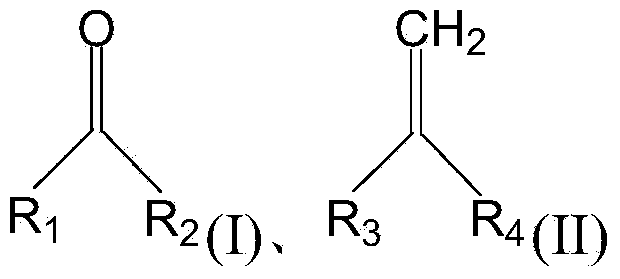

[0038] The invention provides a kind of preparation method of solid acid catalyst, comprises the following steps:

[0039] a) mixing the raw material of the auxiliary agent and the carrier in the first solvent and carrying out the first loading, and then drying and first roasting to obtain the catalyst precursor;

[0040] b) performing a second load on the catalyst precursor and the metal compound obtained in step a) in a second solvent to obtain a catalyst intermediate;

[0041] c) Carrying out the second calcination of the catalyst intermediate obtained in the step b) to obtain a solid acid catalyst.

[0042] In the present invention, the raw material of the auxiliary agent and the carrier are mixed in the first solvent, and then the first loading is carried out, followed by drying and first calcining to obtain the catalyst precursor. In the present invention, there is no special limitation on the order in which the auxiliary agent raw materials and the carrier are added to...

Embodiment 1

[0096] 7.8g H 3 BO 3 , 8.5mL H 3 PO 4 and 130mL deionized water were placed in a 500mL round bottom flask, when H 3 BO 3 After completely dissolving, add 80g of silicon dioxide to it while stirring, then connect the round bottom flask to the mixing device, at 95°C, make B and P elements evenly mixed into the silicon dioxide, after loading for 0.5h, Raise the temperature to 120°C, evaporate the moisture in the carrier loaded with additives, place the dried carrier loaded with additives in a muffle furnace, and perform the first calcination at 300°C for 8 hours to make B and P elements Fully react and fix on the carrier to obtain the catalyst precursor;

[0097] Add 130mL containing 2g Li to the catalyst precursor containing B elements and P elements 2 O deionized aqueous solution, continue to react in a slurry mixing device at 90°C for 2h to obtain a catalyst intermediate;

[0098] Raise the temperature to 125°C, evaporate the water to dryness, place the catalyst interme...

Embodiment 2

[0102] 7.8g H 3 BO 3 , 8.5mL H 3 PO 4 and 130mL deionized water were placed in a 500mL round bottom flask, when H 3 BO 3 After completely dissolving, pour 80g of silica while stirring, connect the round-bottomed flask to the mixing device, load it at a temperature of 20°C for 8 hours, raise the temperature to 120°C, and evaporate to dryness the moisture in the carrier loaded with additives , placing the dry carrier loaded with additives in a muffle furnace, and performing the first calcination at 350° C. for 0.5 h, so that B and P elements are fully reacted and fixed on the carrier to obtain a catalyst precursor;

[0103] Add 130mL containing 2g Li to the catalyst precursor containing B and P elements 2 O deionized aqueous solution, continue to react in a slurry mixing device at 90°C for 2h to obtain a catalyst intermediate;

[0104] Raise the temperature to 125°C, evaporate the moisture in the catalyst intermediate, and then add 130mL of concentrated ammonia water with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com