Microwave sulphur lamp on basis of electron cyclotron resonance discharge

An electron cyclotron resonance and microwave technology, which is applied in the parts and circuits of discharge lamps and gas discharge lamps, can solve the problems of slow start-up time and unstable start-up process of microwave sulfur lamps, achieve rapid ignition process, improve lifespan, Improve the effect of the mean free path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

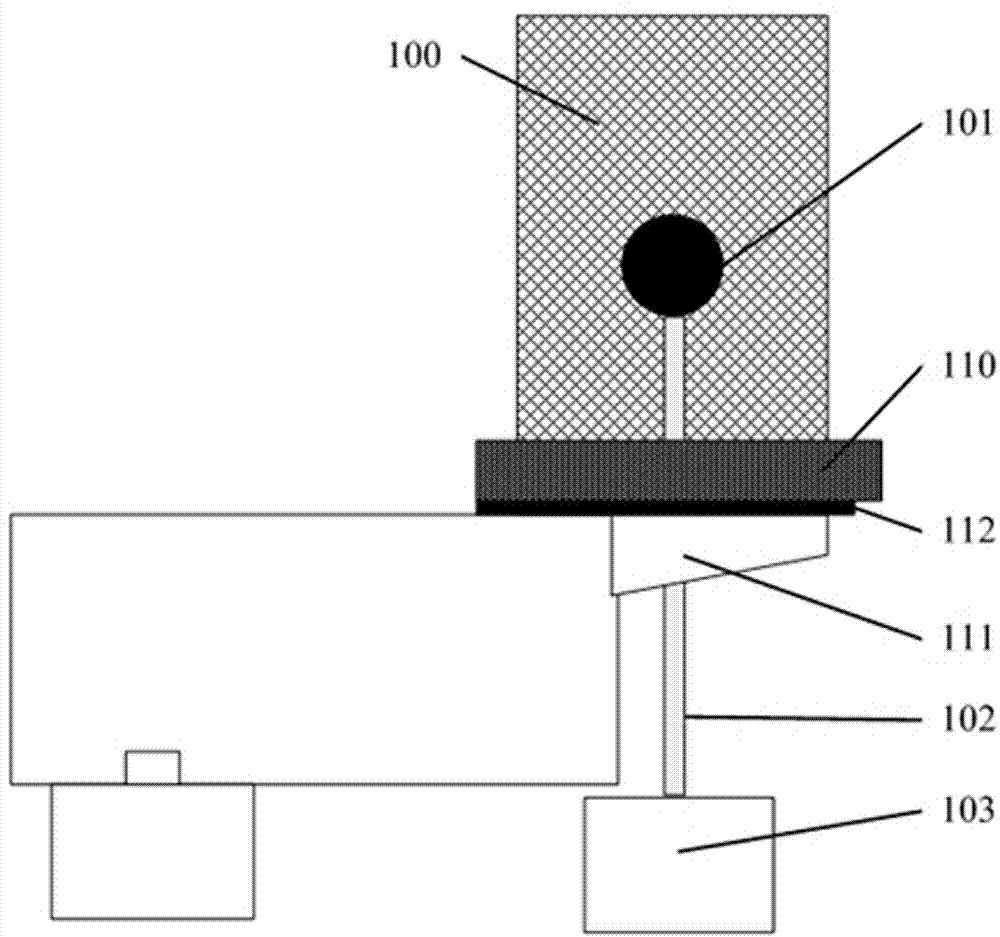

[0031] Such as figure 2 As shown, the magnet 110 is placed at the bottom of the resonant cavity 100, and can be placed inside or outside the resonant cavity 100. In order to better protect the magnet 110, it may be necessary to fill a heat insulating material between the magnet 110, the metal waveguide 104 and the resonant cavity 100. 112, or put a heat-shielding reflector on top of the magnet.

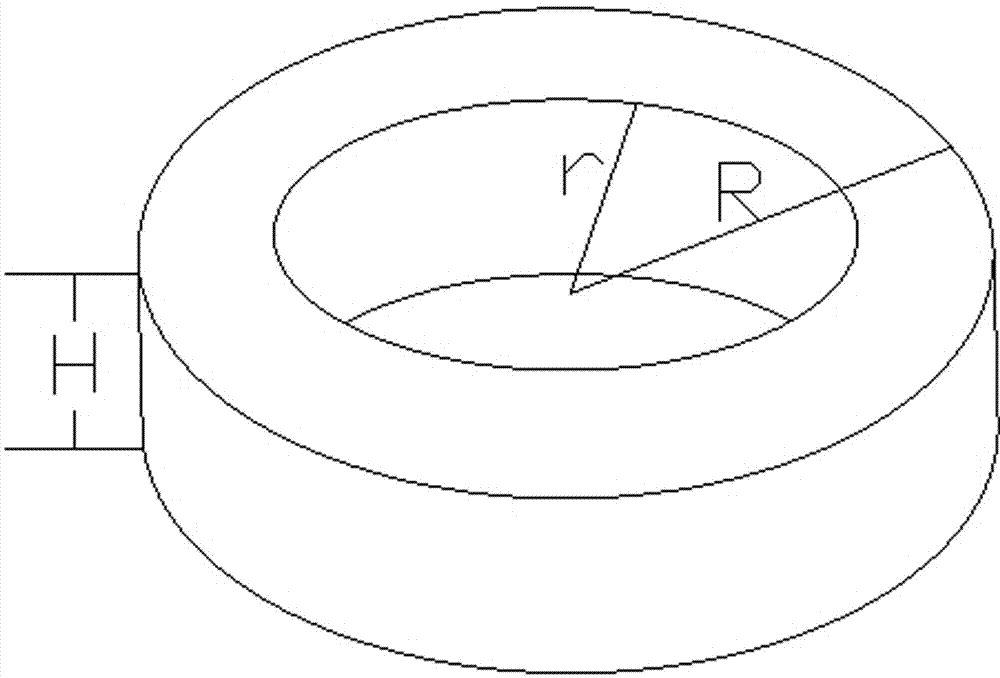

[0032] Such as image 3 As shown, the material of the magnet 110 used in this embodiment is smco28, the inner radius r is consistent with the outer radius R of the metal resonant cavity 100, the outer radius R is 40 mm, and the height H is 20 mm. The distribution of the magnetic field generated by the magnet 100 along the central axis of the magnet is as follows: Figure 4 As shown, at the center of the bulb 101, the axial magnetic field intensity is equal to 875Gs. If the microwave source uses a 2.45GHz magnetron, the electron cyclotron resonance discharge condition is established...

Embodiment 2

[0034] Such as Figure 5 As shown, the magnet 110 is placed in the middle of the resonant cavity 100 , and the axis of the magnet 110 is at the same height as the center of the bulb 101 .

[0035] The material of the magnet 110 used in this embodiment is smco28, the inner radius r is consistent with the outer radius of the metal resonant cavity 100, the outer radius R of the magnet 110 is 38mm, and the height H is 5mm. The distribution of the magnetic field generated by the magnet 110 along the central axis of the magnet is as follows: Image 6 As shown, at the central position of the bulb 101, the peak value of the axial magnetic field intensity is equal to 900Gs, so there are two positions within the range of the bulb where the axial magnetic field intensity is equal to 875Gs. There are two areas in the lamp that meet the electron cyclotron resonance discharge condition, and the electrons in the lamp can obtain continuous heating effect better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com