A kind of high toughness, high weather resistance steel and its manufacturing method

A manufacturing method and high-weather-resistance technology, applied in high-weather-resistance steel and its manufacturing, high toughness field, can solve the problems of lowering yield strength, less low temperature toughness in heat affected zone, lowering tensile strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

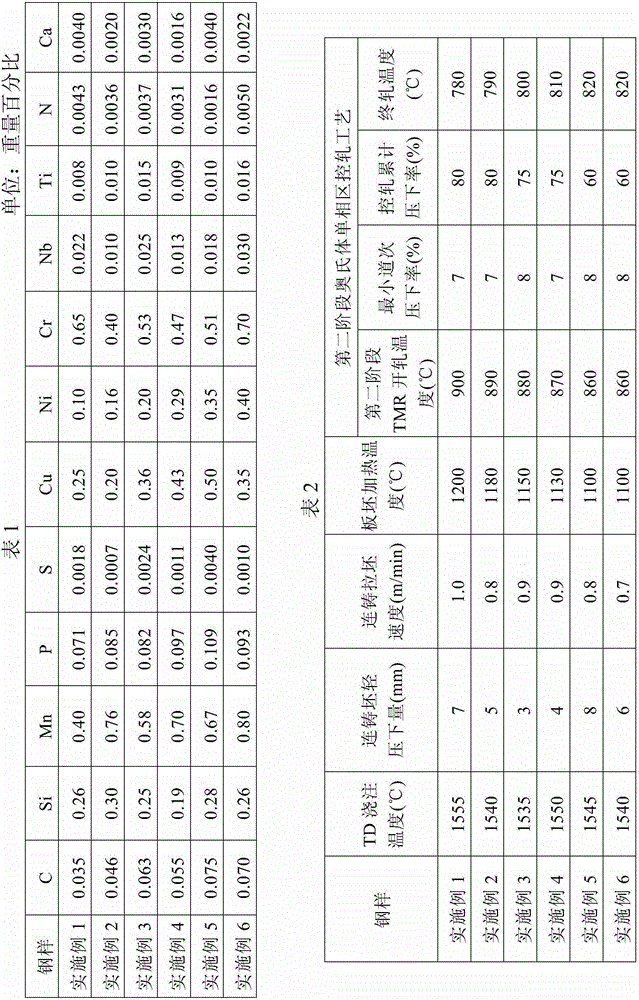

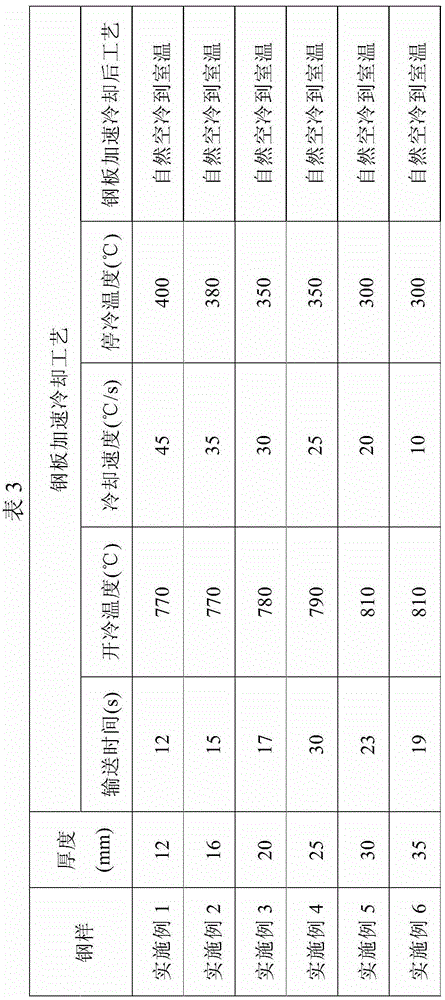

[0055] Table 1 is the composition of the steel of the embodiment of the present invention, and Table 2 is the manufacturing process of the steel of the embodiment of the present invention. Table 3 is the performance of the steel of the embodiment of the present invention.

[0056] The process of the embodiment of the present invention is: TDS molten iron deep desulfurization → converter smelting → LF → RH (feeding Si-Ca wire) → continuous casting (using light reduction process) → slab off-line finishing → slab cut to length → Heating → TMCP → slow cooling of steel plate → AUT / MUT → edge trimming, head and tail cutting of steel plate → sampling and performance inspection → cutting steel plate to length → surface quality and appearance size, marking and testing → delivery.

[0057] see figure 1 , which shows the microstructure of the steel plate in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com