Nano fishbone product as well as preparation method and application of nano fishbone product

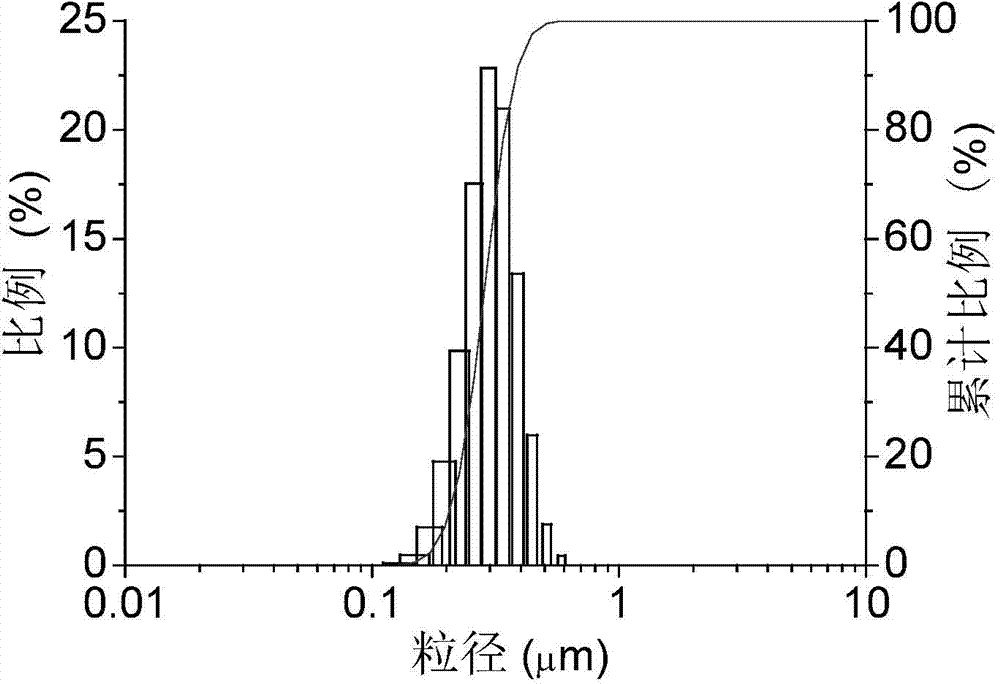

A technology for fish bones and products, which is applied in the field of nano-fish bones and its preparation, can solve the problems of reducing the gel strength of surimi products, the particle size of easy agglomeration of fish bone powder, and low calcium bioavailability, so as to achieve enhanced gel strength and grinding High efficiency, effect of improving texture properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

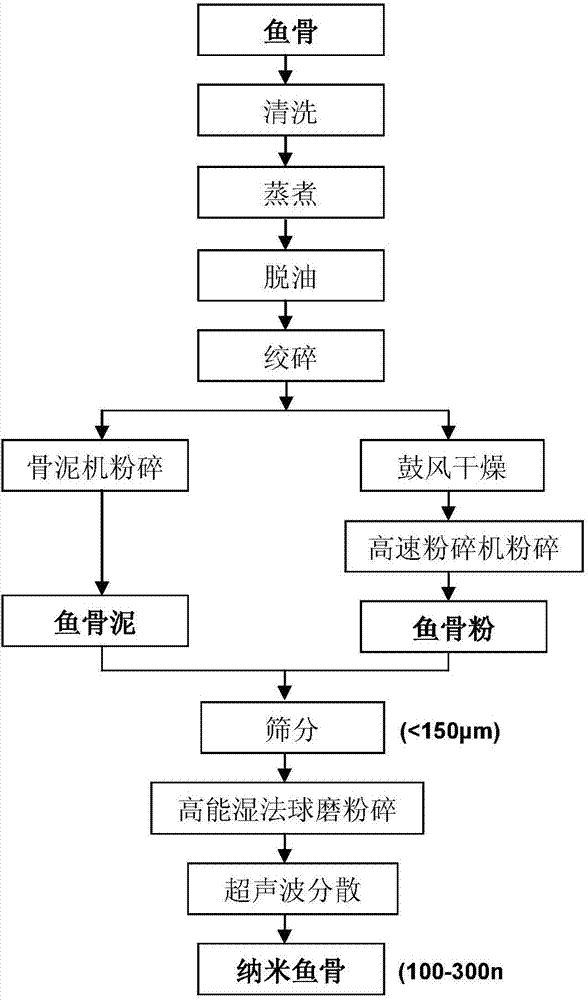

Method used

Image

Examples

Embodiment 1

[0041] First cut the cleaned fish bones (preferably fish bones, or thawed fish bones or fish spines) into long sections of about 3cm, then add 3 times the total amount of clean water to immerse the fish bones, turn Put it into a high-pressure cooking pot and cook and soften at a temperature of 120°C and a pressure of 0.2MPa for 1 hour; after cooking, pour the cooking liquid, then rinse with clean water for 3 times, and then drain the water to remove grease; use a sieve A meat grinder with a plate hole diameter of 10mm is used to crush fish bones, and then wet crushing is carried out with a bone mud machine. First, it is crushed once at a grinding disc gap of 1mm and a rotating speed of 1500rpm, and then at a grinding disc gap of 0.5mm and a rotating speed of 3000rpm. Grinding once, the obtained fish bone mud passes through a 140-mesh sieve; adjust the water content of the fish bone mud to 90%, and transfer it to a high-energy ball mill for grinding. The grinding conditions are:...

Embodiment 2

[0046] First, cut the cleaned fish bones (or thawed fish bones) into long sections of about 3 cm, then add 2 times the total weight of clean water to immerse the fish bones, transfer them to a high-pressure cooking pot and cook them at a temperature of 120°C and a pressure of Cook and soften for 0.5h under the condition of 0.2MPa; after cooking, dump the cooking liquid, then rinse with clean water for 3 times, then drain the water to remove grease; use a meat grinder with a sieve plate aperture of 2mm to break the fish bones, and then Carry out wet crushing with a bone mud machine, first crush once under the condition of a millstone gap of 0.5mm and a rotating speed of 1000rpm, and then crush once under the condition of a millstone gap of 0.1mm and a rotating speed of 2000rpm, and pass the obtained fish bone mud through 140 Purpose sampling sieve; adjust fish bone mud moisture to 90%, transfer to high-energy ball mill for pulverization, grinding conditions are: rotating speed 2...

Embodiment 3

[0048] First, cut the cleaned fish bones (or thawed fish bones) into long sections of about 3 cm, then add 2 times the total weight of clean water to immerse the fish bones, transfer them to a high-pressure cooking pot and cook them at a temperature of 110°C and a pressure of Cook and soften for 1 hour under the condition of 0.14MPa; after cooking, dump the cooking liquid, then rinse with clean water for 3 times, and then drain the water to remove the grease; use a meat grinder with a sieve plate aperture of 5mm to break the fish bones, and then use The bone slime machine performs wet crushing, first crushing once at a grinding disc gap of 1 mm and a rotating speed of 1500 rpm, and then at a grinding disc gap of 0.1 mm and a rotating speed of 2000 rpm. Sample sieve; adjust the water content of the fish bone mud to 90%, and transfer it to a high-energy ball mill for crushing. The grinding conditions are: rotating speed 2500rpm, grinding medium size 2cm, medium filling volume 75%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com