A kind of preparation method of nanometerized carbon-coated lithium titanate negative electrode material

A technology for carbon-coated lithium titanate and negative electrode materials, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high production cost, agglomeration phenomenon, high price, etc., and achieve savings The effect of production cost, reduction of manufacturing cost, and improvement of material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

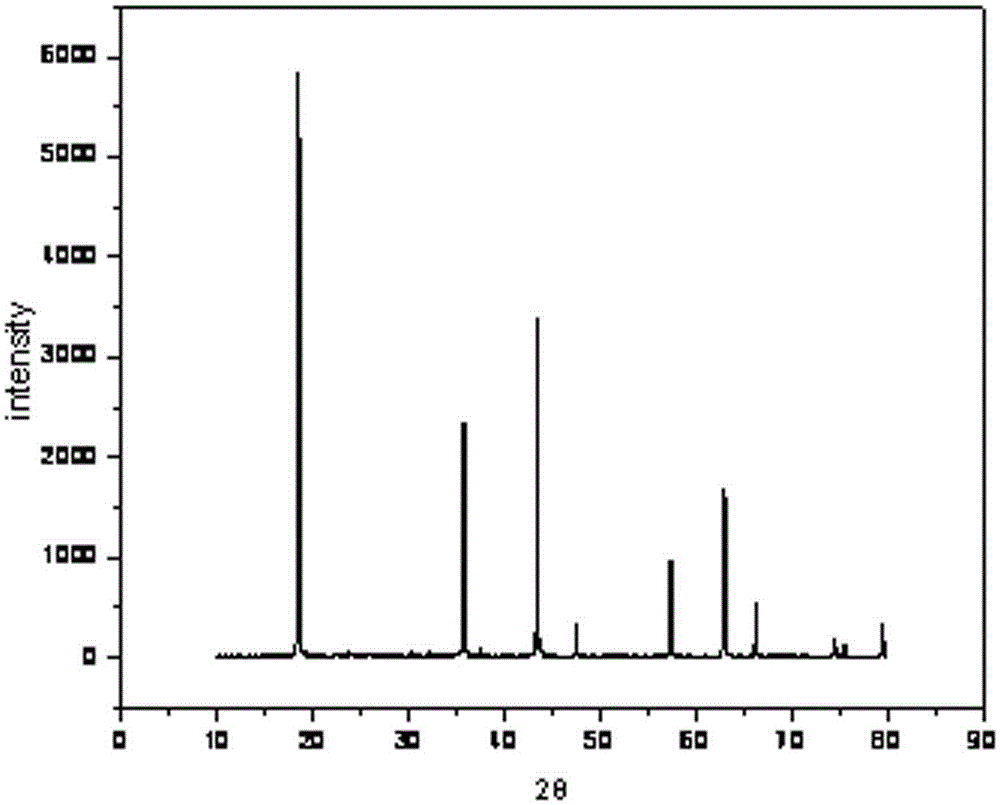

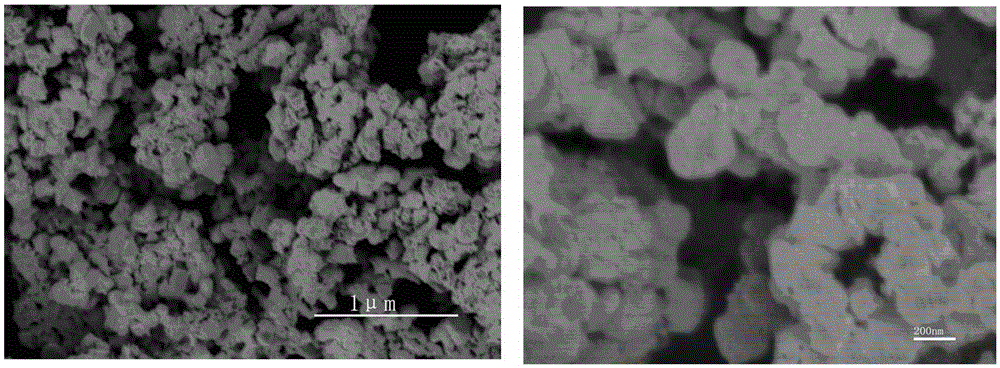

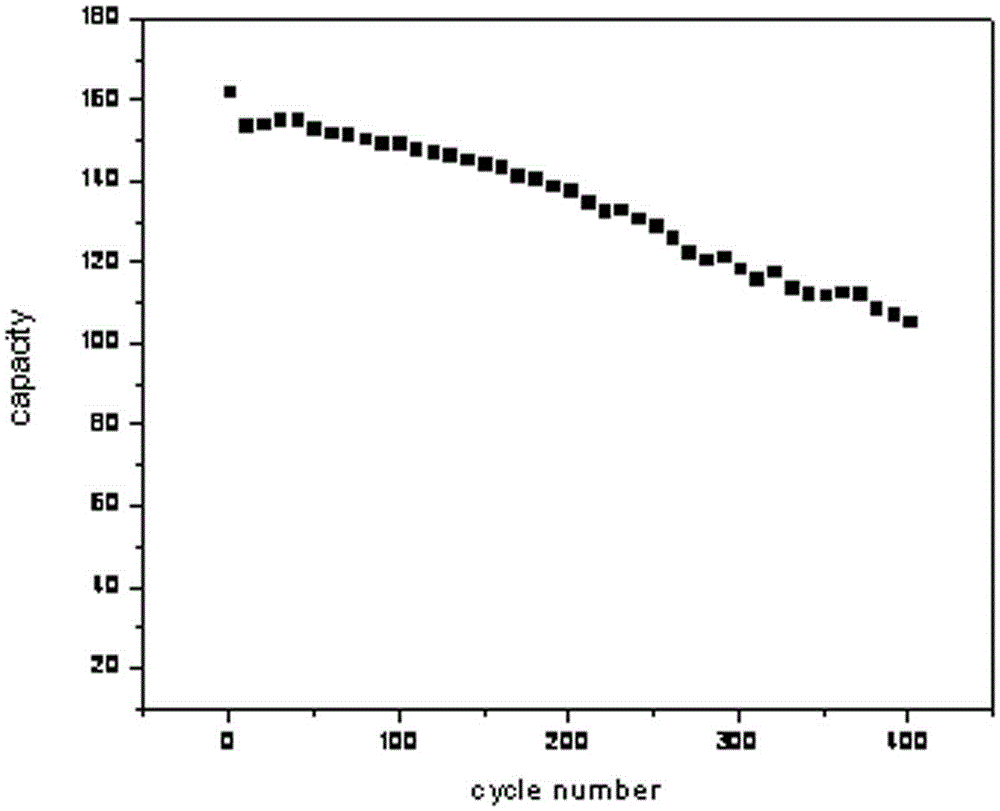

[0021] A preparation method of a nano-sized and carbon-coated composite lithium titanate negative electrode material, comprising the following steps:

[0022] (1) Prepare 8mol / L strong alkali solution, measure 80ml and add it to a 100ml autoclave polytetrafluoroethylene lining, then weigh 2g of titanium dioxide and add it, and then put it in an oven at 160°C for 5 hours. After the reaction, the precipitate in the polyethylene lining of the autoclave was washed several times with hydrochloric acid, then washed with distilled water and filtered, and finally placed in a drying device at 100°C for 5 hours; (2) according to the Li:Ti molar ratio of 0.84 : 1 Weigh lithium carbonate and titanium dioxide powder material after pretreatment, place ball mill jar; Then weigh and then weigh the soluble carbon source (relative to Ti salt) of 0.2 times molar mass, add in the beaker and dissolve with a small amount of distilled water, and then Transfer all the materials into a ball mill jar a...

Embodiment 2

[0025] (1) Prepare a 6mol / L strong alkali solution, measure 80ml and add it to a 100ml autoclave polytetrafluoroethylene lining, then weigh 2g of titanium dioxide and add it, and then place it in an oven at 180°C for 3 hours. After the reaction, the precipitate in the polyethylene lining of the autoclave was washed several times with hydrochloric acid, then washed with distilled water and filtered, and finally placed in a drying device at 100°C for 5 hours; (2) according to the Li:Ti molar ratio of 0.84 : 1 Weigh lithium carbonate and titanium dioxide powder material after pretreatment, place ball mill jar; Then weigh and then weigh the soluble carbon source (relative to Ti salt) of 0.2 times molar mass, add in the beaker and dissolve with a small amount of distilled water, and then Transfer all the materials into a ball mill jar and put them into agate balls for milling for 1 hour; (3) Quickly dry the above-mentioned materials through spray drying equipment, then transfer all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com