Forging and heat treatment process for aero-engine aluminium alloy vane

An aero-engine and aluminum alloy technology, which is applied in the direction of engine components, mechanical equipment, etc., can solve problems such as the failure of the tensile strength of aluminum alloy forgings to meet the technical requirements, meet the tensile strength at room temperature, avoid cracking problems, and reduce aging treatment The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

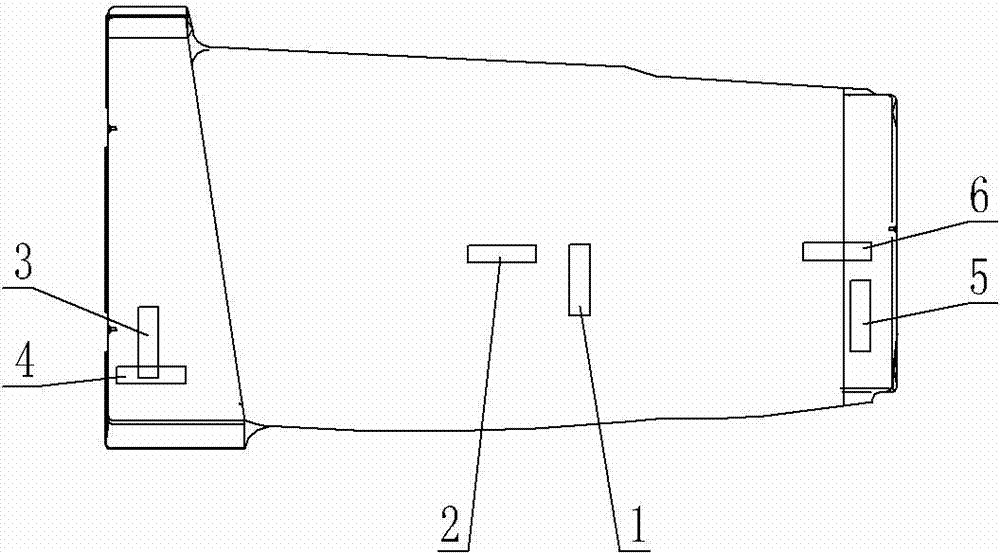

Image

Examples

Embodiment 1

[0019] A forging and heat treatment process for aero-engine aluminum alloy blades. First, the Al-Cu-Mn-Zr-V-Ti aluminum alloy blade blank is heated for forging, and the aluminum alloy blade blank is placed in a heating furnace and heated to 460°C. For 5.5 hours, put the aluminum alloy blade blank into the press for die forging deformation, and the die forging deformation was controlled at 20% to obtain aluminum alloy blade forgings; then the obtained aluminum alloy blade forgings were heat treated, including quenching treatment in turn And aging treatment, in which the quenching treatment is to heat the aluminum alloy blade forgings in a quenching furnace to 535°C and hold for 3 hours, then water-cooled to room temperature, the water-cooling temperature is 71°C; the aging treatment is the quenched aluminum alloy The blade forging is placed in a heating furnace and heated to 165°C with the furnace and kept for 26 hours, then air-cooled to room temperature.

[0020] An aeroengine a...

Embodiment 2

[0022] An aeroengine aluminum alloy blade forging and heat treatment process. First, the Al-Cu-Mn-Zr-V-Ti aluminum alloy blade blank is heated for forging, and the aluminum alloy blade blank is placed in a heating furnace and heated to 455°C. After 4.5 hours, the aluminum alloy blade blank was put into the press for die forging deformation, and the die forging deformation was controlled at 60% to obtain aluminum alloy blade forgings; then the obtained aluminum alloy blade forgings were heat treated, including quenching treatment in turn And aging treatment, wherein the quenching treatment is to heat the aluminum alloy blade forgings in a quenching furnace to 541°C and hold for 3 hours, then water-cooled to room temperature, and the water-cooling temperature is 66°C; the aging treatment refers to the quenched aluminum alloy The blade forging is placed in a heating furnace and heated to 175°C with the furnace and kept for 26 hours, then air-cooled to room temperature.

[0023] An a...

Embodiment 3

[0025] An aeroengine aluminum alloy blade forging and heat treatment process. First, the Al-Cu-Mn-Zr-V-Ti aluminum alloy blade blank is heated for forging, and the aluminum alloy blade blank is placed in a heating furnace and heated to 465°C. After 5 hours, put the aluminum alloy blade blank into the press for die forging deformation, and the die forging deformation was controlled at 40% to obtain aluminum alloy blade forgings; then the obtained aluminum alloy blade forgings were heat treated, including quenching treatment in turn And aging treatment, in which the quenching treatment is to heat the aluminum alloy blade forgings in a quenching furnace to 529°C and hold for 3 hours, then water-cool to room temperature, and the water-cooling temperature is 60°C; the aging treatment is the quenched aluminum alloy The blade forging is placed in a heating furnace and heated to 170°C with the furnace and kept for 26 hours, then air-cooled to room temperature.

[0026] An aeroengine alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com