Method for obtaining high-purity hesperetin from valeriana jatamansi residue

A technology of hesperetin and spider scent, which is applied in the field of obtaining high-purity hesperetin, can solve the problems of low yield, large environmental impact, and high cost, and achieve easy industrial production, improved enzymatic conversion rate, and resource utilization high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

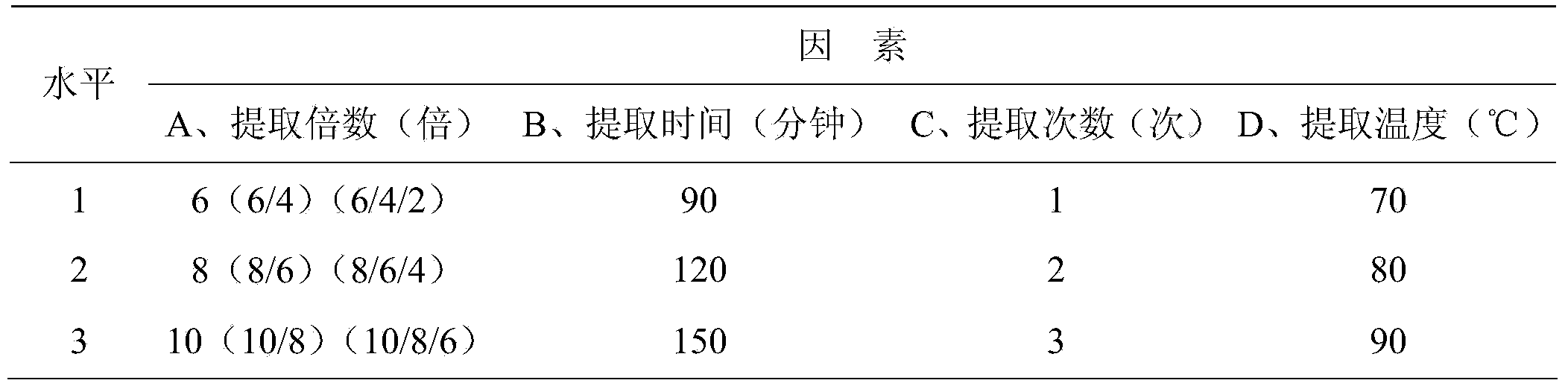

Method used

Image

Examples

Embodiment 1

[0061] By analyzing the results of the above extraction and enzymatic hydrolysis process, it is determined that the best method for extracting and separating hesperetin from the spider incense residue after extracting total terpenes of the present invention includes the following steps:

[0062] 1) Take 10kg of the spider incense extract residue after extracting the total terpenes, with a hesperidin content of 1%, and extract twice at 90°C with an aqueous solution of calcium hydroxide with a mass concentration of 5%, and the first addition is 80L. 2h, the second addition is 60L, extract for 2h, combine and filter the extracts, adjust the pH value to 8-9 with 5% calcium hydroxide aqueous solution, and set aside;

[0063] 2) Put the pH-adjusted extract on a macroporous resin column, the resin type is AB-8, the pH value is 8-9, the volume of the extract is 120L, and the adsorption flow rate is 1.5BV / h. After the adsorption is saturated, use Elute with deionized water. When the ef...

Embodiment 2

[0077] 1) Take 10kg of the spider incense extract residue after extracting the total terpenes, with a hesperidin content of 1%, and extract twice at 90°C with an aqueous solution of calcium hydroxide with a mass concentration of 5%, and the first addition is 80L. 2h, the second addition is 60L, extract for 2h, combine and filter the extracts, adjust the pH value to 8-9 with 5% calcium hydroxide aqueous solution, and set aside;

[0078] 2) Put the pH-adjusted extract on a macroporous resin column, the resin type is AB-8, the pH value is 8-9, the volume of the extract is 120L, and the adsorption flow rate is 1.5BV / h. After the adsorption is saturated, use Elute with deionized water. When the effluent is clarified, the washed column packing is eluted with sodium hydroxide eluent with a mass concentration of 0.8% to 1%. The amount of eluent is 50L, and the flow rate is 1BV / h. eluent;

[0079] 3) Pour the obtained eluent into the reaction kettle, adjust the pH to 4 with 5% hydroch...

Embodiment 3

[0083] 1) Take 10kg of the spider incense extract residue after extracting the total terpenes, with a hesperidin content of 1%, and extract twice at 90°C with an aqueous solution of calcium hydroxide with a mass concentration of 5%, and the first addition is 80L. 2h, the second addition is 60L, extract for 2h, combine and filter the extracts, adjust the pH value to 8-9 with 5% calcium hydroxide aqueous solution, and set aside;

[0084] 2) Put the extract after adjusting the pH value on the macroporous resin column, the resin model is AB-8, the pH value is 8-9, the volume of the extract is 120L, and the adsorption flow rate is 1.5BV / h. After the adsorption is saturated, use Elute with deionized water. When the effluent is clarified, the washed column packing is eluted with sodium hydroxide eluent with a mass concentration of 0.8% to 1%. The amount of eluent is 50L, and the flow rate is 1BV / h. eluent;

[0085] 3) Pour the obtained eluent into the reaction kettle, adjust the pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com