Continuous flow biological denitrification method and device based on granular sludge

A granular sludge and biological denitrification technology, which is applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of affecting the anaerobic ammonium oxidation process, low dissolved oxygen concentration, and system start-up time Long-term problems, to achieve the effect of improving the activity of anaerobic ammonium oxidation, improving the activity of ammonia oxidation, and lowering the technical threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

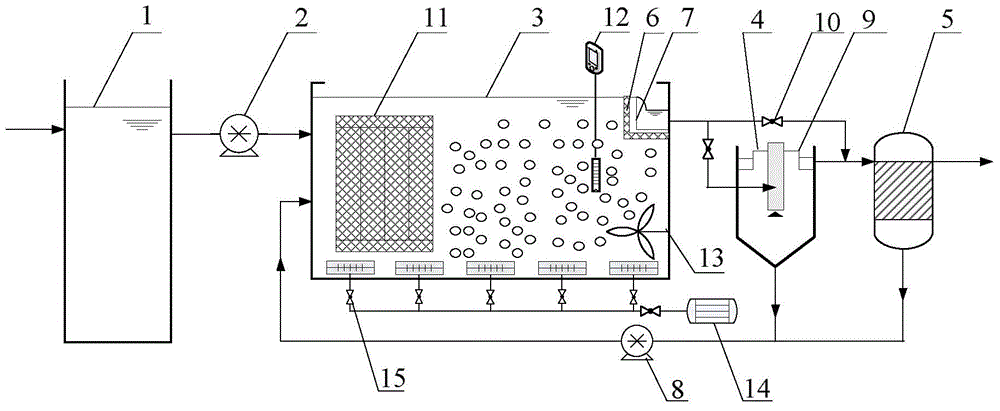

[0029] The present invention will be further described below in conjunction with accompanying drawing and embodiment: figure 1 As shown, the continuous flow short-path nitrification-ANAMMOX biological denitrification device based on granular sludge is sequentially connected to the water inlet tank 1, bioreactor 3, and sedimentation tank for storing waste water with high ammonia nitrogen and low carbon-to-nitrogen ratio 4 and a hydraulic sieve filter 5; the high ammonia nitrogen waste water to be treated is connected with the water inlet tank 1 through the water inlet, and the water outlet of the water inlet tank 1 is communicated with the water inlet of the bioreactor 3 through the water inlet pump 2; the bioreactor 3 The mixed liquid passes through the filter screen 6 and the overflow weir 7 in turn, and communicates with the central cylinder of the sedimentation tank 4 through pipes and valves; after the mud-water separation in the sedimentation tank 4 is completed, the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com