A kind of preparation method of halloysite nanotube-sulfonic acid group-cr (iii) ion acidic composite catalyst

A technology of halloysite nanotubes and composite catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve problems such as insoluble cellulose, achieve high recovery rate, good selectivity, strong The effect of catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

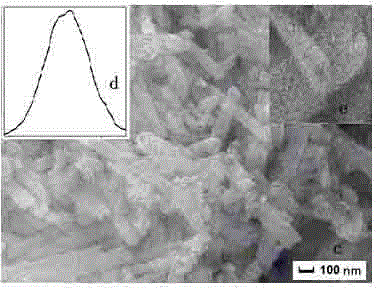

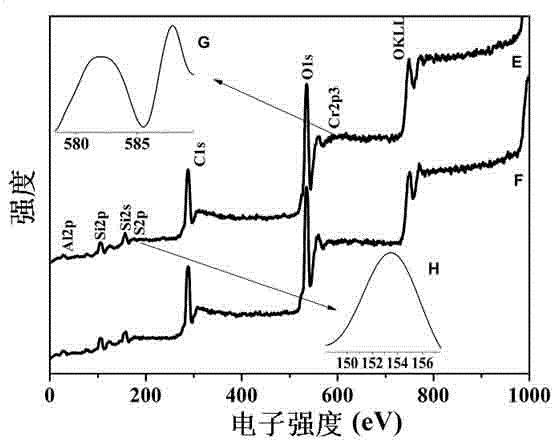

[0031] A preparation method of halloysite nanotube-sulfonic acid group-Cr (III) ion acidic composite catalyst is characterized in that it is carried out according to the following steps:

[0032] 1. Catalyst Synthesis

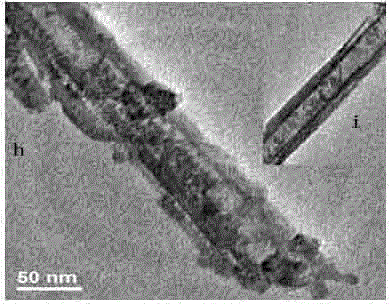

[0033] (1) Synthesis of thiolated halloysite nanotubes:

[0034]0.8 g of the treated halloysite nanotubes were added to a three-necked flask containing 40 mL of toluene, and then 7.5 mL of silane coupling agent 3-(mercaptopropyl)trimethoxysilane was added to the whole system, and after mixing The system was heated to reflux at 110 °C for 24 h. The obtained product was filtered and washed 3 times with toluene to remove residual 3-(mercaptopropyl)trimethoxysilane, and the filtered solid was vacuum-dried at 70 °C.

[0035] (2) Synthesis of sulfonated halloysite nanotubes:

[0036] Add 0.43 g of thiol-modified halloysite nanotubes into a three-necked flask, then add 7.8 mL of 30% hydrogen peroxide, 9.5 mL of distilled water, and 8.6 mL of methanol into the sys...

Embodiment 2

[0052] A preparation method of halloysite nanotube-sulfonic acid group-Cr (III) ion acidic composite catalyst is characterized in that it is carried out according to the following steps:

[0053] 1. Catalyst Synthesis

[0054] (1) Synthesis of thiolated halloysite nanotubes:

[0055] 1.2 g of the treated halloysite nanotubes were added to a three-necked flask containing 40 mL of toluene, and then 8.5 mL of silane coupling agent 3-(mercaptopropyl)trimethoxysilane was added to the whole system, and after mixing, The system was heated to reflux at 110 °C for 24 h, the obtained product was filtered and washed 5 times with toluene to remove residual 3-(mercaptopropyl)trimethoxysilane, and the filtered solid was vacuum-dried at 80 °C.

[0056] (2) Synthesis of sulfonated halloysite nanotubes:

[0057] Add 0.57 g of mercapto-modified halloysite into a three-necked flask, then add 12.2 mL of 30% hydrogen peroxide, 10.5 mL of distilled water, and 11.4 mL of methanol into the system, ...

Embodiment 3

[0067] A preparation method of halloysite nanotube-sulfonic acid group-Cr (III) ion acidic composite catalyst is characterized in that it is carried out according to the following steps:

[0068] 1. Catalyst Synthesis

[0069] (1) Synthesis of thiolated halloysite nanotubes:

[0070] 1.0 g of the treated halloysite nanotubes were added to a three-necked flask containing 40 mL of toluene, and then 8.0 mL of silane coupling agent 3-(mercaptopropyl)trimethoxysilane was added to the whole system, and after mixing The system was heated to reflux at 110 °C for 24 h, and the obtained product was filtered and washed with toluene four times to remove residual 3-(mercaptopropyl)trimethoxysilane, and the filtered solid was vacuum-dried at 75 °C.

[0071] (2) Synthesis of sulfonated halloysite nanotubes:

[0072] Add 0.50 g of mercapto-modified halloysite into a three-necked flask, then add 10.0 mL of 30% hydrogen peroxide, 10.0 mL of distilled water, and 10.0 mL of methanol into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com