Preparation method and silicon modification method of visible light catalysis material for graphene/bismuth tungstate flake nanostructure

A nanostructure and catalytic material technology, applied in the field of photocatalytic materials, can solve the problems of low photocatalytic efficiency, limit the wide application of bismuth tungstate, and low photon quantum yield, and achieve enhanced interaction, improved photocatalytic efficiency, and improved dispersion and the effect of surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

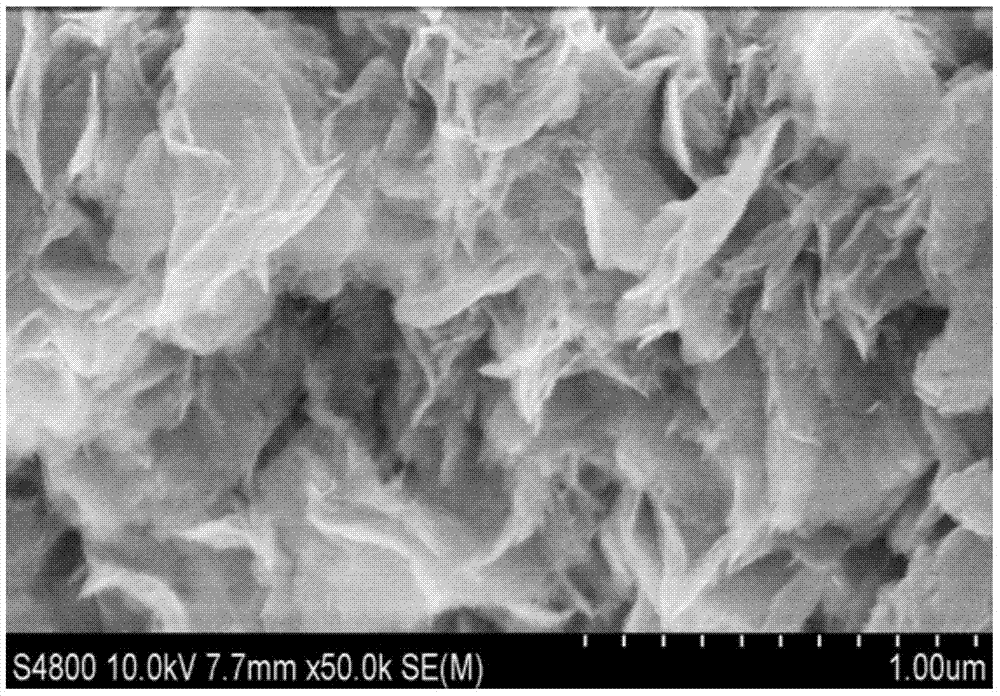

[0028] Example 1 (without silicon modification)

[0029] (1) Add 3 mL of graphene oxide solution with a concentration of 0.6 g / L into 70 mL of deionized water and ultrasonically disperse for 30 min to obtain a stable graphene dispersion;

[0030] (2) Stir and ultrasonically disperse the above solution at a temperature of 0-40°C for 15-30 min to obtain a uniformly dispersed solution;

[0031] (3) Add 0.3 g sodium tungstate, an organic electrolyte composed of 2 g polyacrylic acid (polyacrylic acid 800-1000) and 0.8 g cetyltrimethylammonium bromide to the above solution, stir and dissolve, and place in Continue ultrasonic stirring at 35°C for 15 min; freeze at 0°C for 14 h, then add 0.45 g of bismuth nitrate under ultrasonic stirring, and ultrasonically stir for 30 min to obtain a colloidal solution;

[0032] (4) Aging the colloidal solution described in step (3) at room temperature (25°C) for 2 hours, and then transferring it to a reaction kettle with a volume of 100 mL for 10 ...

Embodiment 2

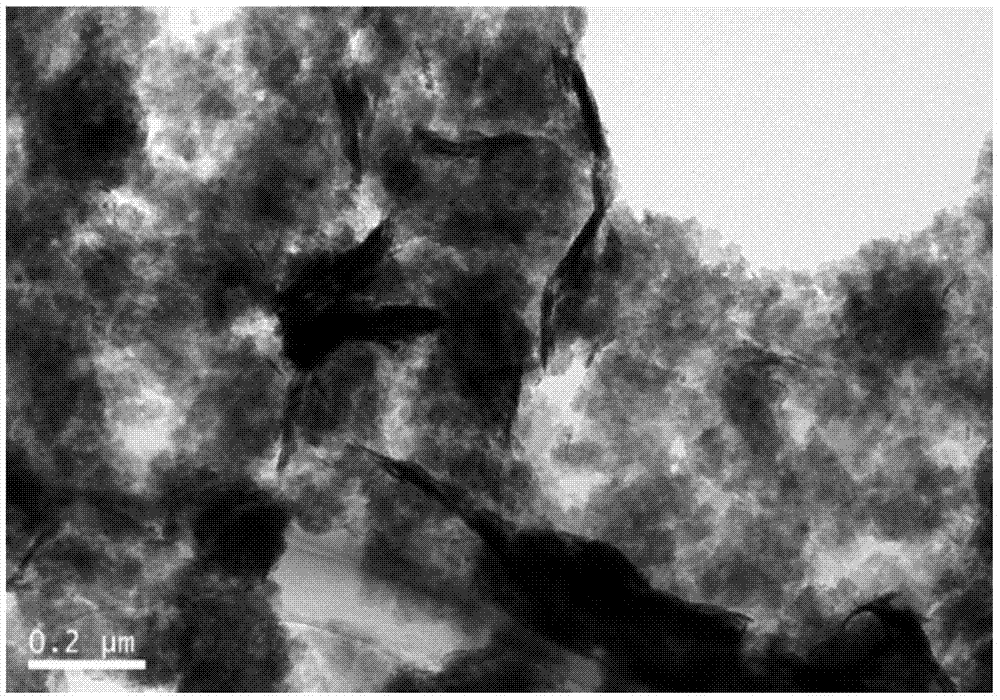

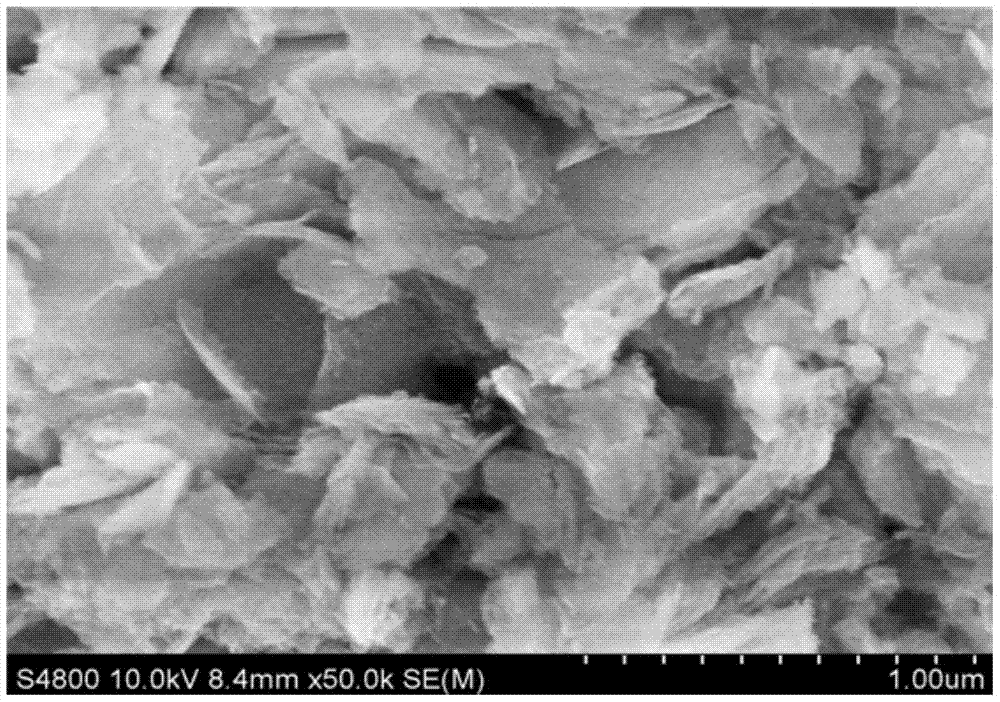

[0034] Embodiment 2: (carry out silicon modification)

[0035] (1) Add 12 mL of reduced graphene oxide solution with a concentration of 0.8 g / L into 60 mL of deionized water and ultrasonically disperse for 40 min to obtain a stable graphene dispersion;

[0036] (2) Add 3 mL tetraethyl orthosilicate to the above solution, then stir and ultrasonically disperse at 30°C for 30 min to obtain a uniformly dispersed solution, and let it stand for 18 h;

[0037] (3) Add 3.042 g of ammonium tungstate, an organic electrolyte composed of 2 g of polyacrylic acid and 0.8 g of hexadecyltrimethylammonium bromide to the above solution, stir and dissolve, and continue ultrasonic stirring at a temperature of 40°C 30 min; freeze at -10°C for 12 h, then add 0.8 g of bismuth nitrate under ultrasonic stirring, and ultrasonically stir for 30 min to obtain a colloidal solution;

[0038] (4) Aging the colloidal solution described in step (3) at room temperature (25 °C) for 1 h, and then transferring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com