Electrochemical sensor for detecting bisphenol A, preparation method and application thereof

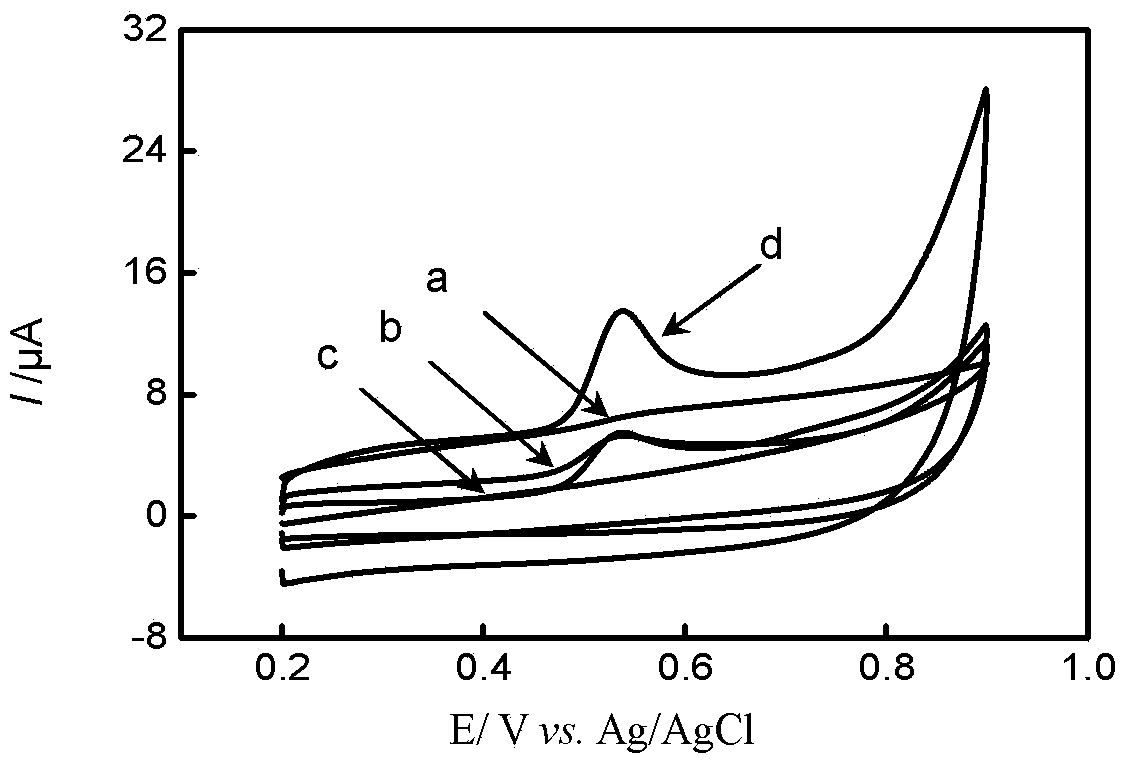

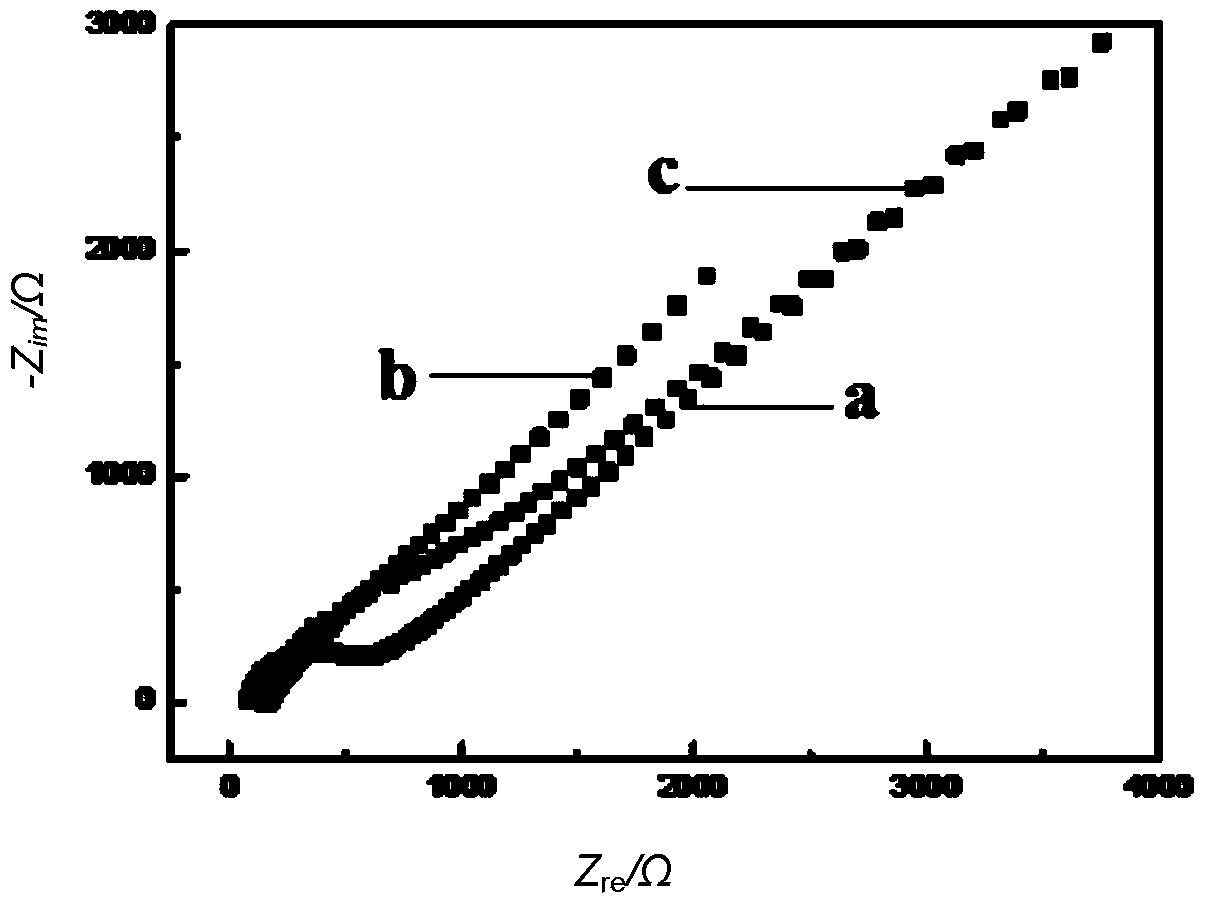

A sensor and electrochemical technology, applied in the direction of material electrochemical variables, nanotechnology for sensing, nanotechnology, etc., can solve the problems of poor selectivity, stability, and low sensitivity, and achieve good stability and expand electrocatalysis The effect of high area and detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The first step, glassy carbon electrode pretreatment:

[0037] (a) The glassy carbon electrode is sequentially polished to a mirror surface with 1.0 μm, 0.3 μm and 0.05 μm alumina powder on a polishing cloth;

[0038] (b) ultrasonically clean the glassy carbon electrode twice in secondary water for 2-5 minutes each time, and then dry it;

[0039] (c) Put the glassy carbon electrode at 0.1mol·L -1 In the potassium ferricyanide solution, a cyclic voltammetry scan was performed between -0.4 and +0.7 V until a typical cyclic voltammetry pattern was obtained, resulting in a clean glassy carbon electrode.

[0040] In the second step, the electrode surface is modified with aminated carbon nanotubes:

[0041] Disperse the aminated carbon nanotubes in DMF and disperse them ultrasonically to obtain a DMF dispersion of the aminated carbon nanotubes with a concentration of 1 g. L -1 ;

[0042] Add 10 μL of the dispersion liquid dropwise to the clean glassy carbon electrode pre...

Embodiment 2

[0072] According to the steps of Example 1, only the amount of the dispersion used in the second step was replaced from 10 μL to 5 μL;

[0073] The concentration of glutamic acid used in the third step was replaced by 0.1mol. L -1 , the number of scanning circles is replaced by 6 circles to 3 circles, and the electrochemical sensor provided by the present invention is obtained.

[0074] The electrochemical sensor includes a glassy carbon electrode; on the surface of the glassy carbon electrode, there are aminated multi-walled carbon nanotubes and a network composed of polyglutamic acid (n is 1000-15000) shown in formula I in sequence from inside to outside Polyglutamic acid film; the thickness of the aminated carbon nanotube is 15-150nm; the outer diameter is 8-15nm; the inner diameter is 2-4nm; the length is 50μm; the thickness of the polyglutamic acid film is 5nm.

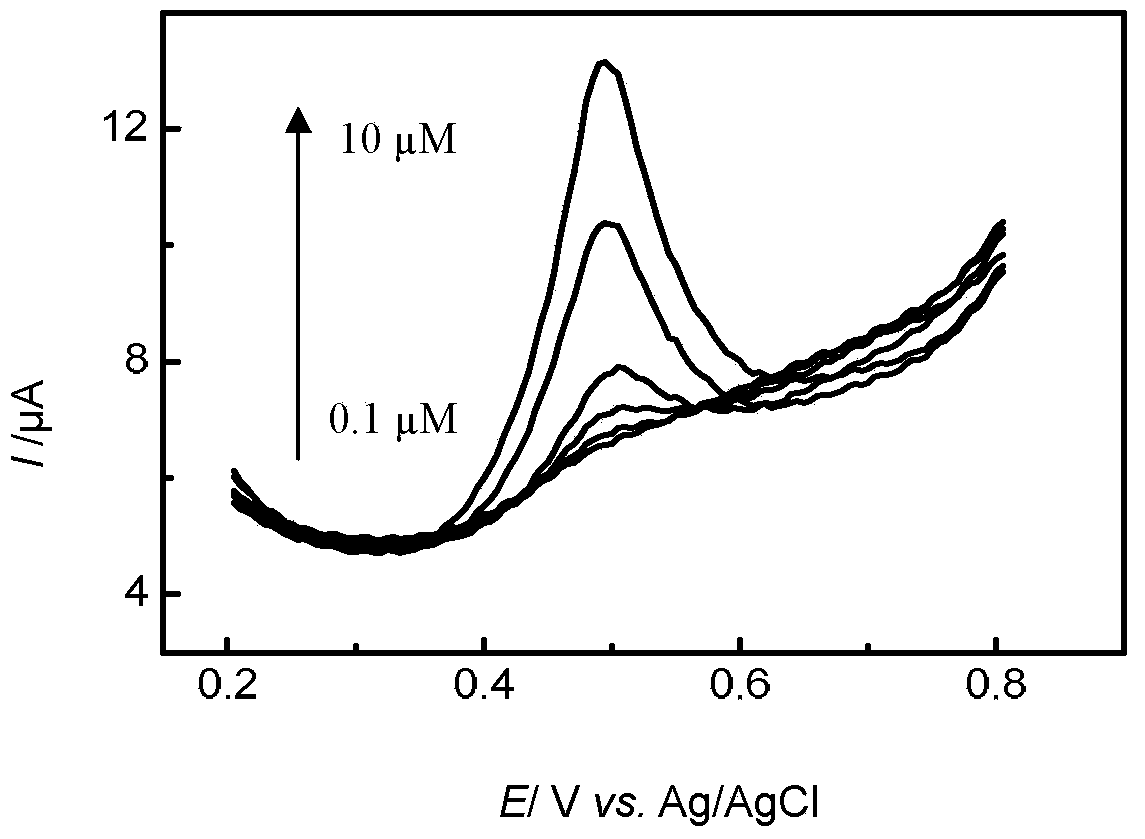

[0075] Utilize the electrochemical sensor obtained in this embodiment to carry out the detection of bispheno...

Embodiment 3

[0082] According to the step of Example 1, only the concentration of the DMF dispersion in the second step is replaced by 0.7g. L -1 ;

[0083] In the third step, the concentration of the phosphate buffer solution of glutamic acid is replaced by 0.015mol. L -1 , and the number of scanning circles was replaced by 10 circles to obtain the electrochemical sensor provided by the present invention.

[0084] The electrochemical sensor includes a glassy carbon electrode; on the surface of the glassy carbon electrode, there are aminated multi-walled carbon nanotubes and a network composed of polyglutamic acid (n is 1000-15000) shown in formula I in sequence from inside to outside Polyglutamic acid film; the thickness of the aminated carbon nanotube is 15-150nm; the outer diameter is 8-15nm; the inner diameter is 2-4nm; the length is 50μm; the thickness of the polyglutamic acid film is 5nm.

[0085] Utilize the electrochemical sensor obtained in this embodiment to carry out the det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com