A method for extracting metals and preparing oxygen from lunar rock-type mixed oxides

A technology for mixing oxides and extracting metals, applied in the field of metallurgy, can solve the problems of not reaching the purity of industrial aluminum ingots and difficult to use raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

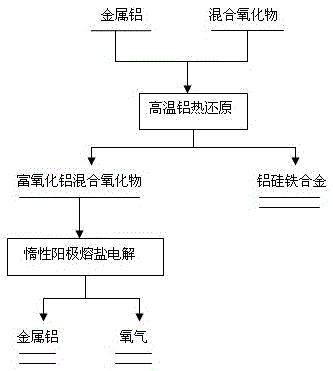

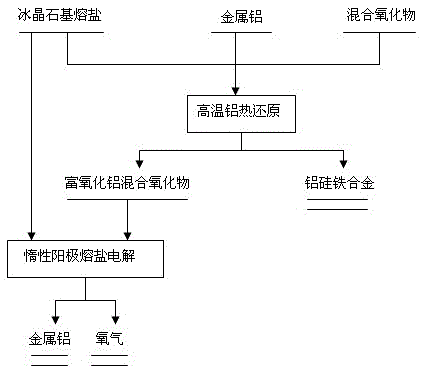

Image

Examples

Embodiment 1

[0028] In this example, the composition content (mass percentage) of lunar rock-type mixed oxides in lunar soil is as follows: 20% SiO 2 , 60%Al 2 o 3 , 0%FeO, 1%Fe 2 o 3 , 4%MgO, 15%CaO.

[0029] (1) Under the condition of isolated air, metal aluminum is used as the reducing agent, and the amount of metal aluminum is twice the molar amount of the theoretical reducing agent required for the reduction of lunar soil and lunar rock-type mixed oxides. The oxide was subjected to aluminothermic reduction for 2 hours, and then slag-gold separation was performed to obtain Al-Si-Fe alloy and Al-rich 2 o 3 mixed oxides;

[0030] The obtained Al-Si-Fe alloy contains Al90%, Si8%, Fe1% by weight percentage, and the balance is impurities;

[0031] (2) will be rich in Al 2 o 3 Mixed oxides dissolved in cryolite-based molten salt electrolyte Na 3 AlF 6 -AlF 3 Medium, rich Al 2 o 3 The amount of mixed oxide added is Al-rich 2 o 3 5% of the total weight of mixed oxide and cryoli...

Embodiment 2

[0035]In this embodiment, the composition content (mass percentage) of lunar rock-type mixed oxides in lunar soil is as follows: 30% SiO 2 , 40%Al 2 o 3 , 10%FeO, 3%Fe 2 o 3 , 2%MgO, 15%CaO.

[0036] (1) Under the condition of isolated air, metal aluminum is used as the reducing agent, and the amount of metal aluminum is 3 times the molar amount of the theoretical reducing agent required for the reduction of lunar soil and lunar rock-type mixed oxides. The oxide was subjected to aluminothermic reduction for 3h, followed by slag-gold separation to obtain Al-Si-Fe alloy and Al-rich 2 o 3 mixed oxides;

[0037] The obtained Al-Si-Fe alloy contains Al86%, Si9%, Fe4% by weight percentage, and the balance is impurities;

[0038] (2) will be rich in Al 2 o 3 Mixed oxides dissolved in cryolite-based molten salt electrolyte Na 3 AlF 6 -AlF 3 Medium, rich Al 2 o 3 The amount of mixed oxide added is Al-rich 2 o 3 4% of the total weight of mixed oxide and cryolite-based mo...

Embodiment 3

[0042] In this example, the composition content (mass percentage) of lunar rock-type mixed oxides in lunar soil is as follows: 40% SiO 2 , 30%Al 2 o 3 , 5%FeO, 8%Fe 2 o 3 , 2%MgO, 15%CaO.

[0043] (1) Under the condition of isolated air, metal aluminum is used as the reducing agent, and the amount of metal aluminum is 4 times the molar amount of the theoretical reducing agent required for the reduction of lunar soil and lunar rock-type mixed oxides. The oxide was subjected to aluminothermic reduction for 4h, followed by slag-gold separation to obtain Al-Si-Fe alloy and Al-rich 2 o 3 mixed oxides;

[0044] The obtained Al-Si-Fe alloy contains Al86%, Si9%, Fe4% by weight percentage, and the balance is impurities;

[0045] (2) will be rich in Al 2 o 3 Mixed oxides dissolved in cryolite-based molten salt electrolyte Na 3 AlF 6 -AlF 3 Medium, rich Al 2 o 3 The amount of mixed oxide added is Al-rich 2 o 3 6% of the total weight of mixed oxide and cryolite-based molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com