Silicon melt external refining device and method

An out-of-furnace refining and silicon melt technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of insufficient stirring of silicon melt, affecting product quality, uneven composition, etc., and achieves easy large-scale Industrial application, improvement of silicon product quality, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

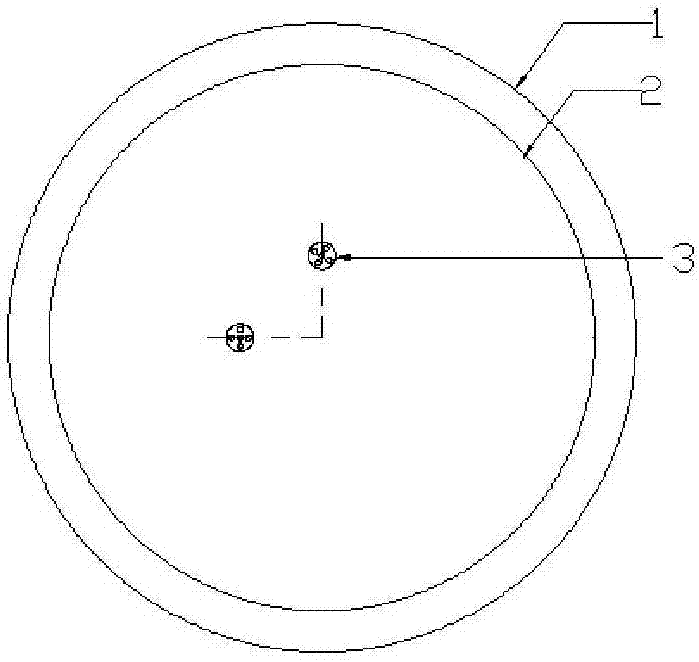

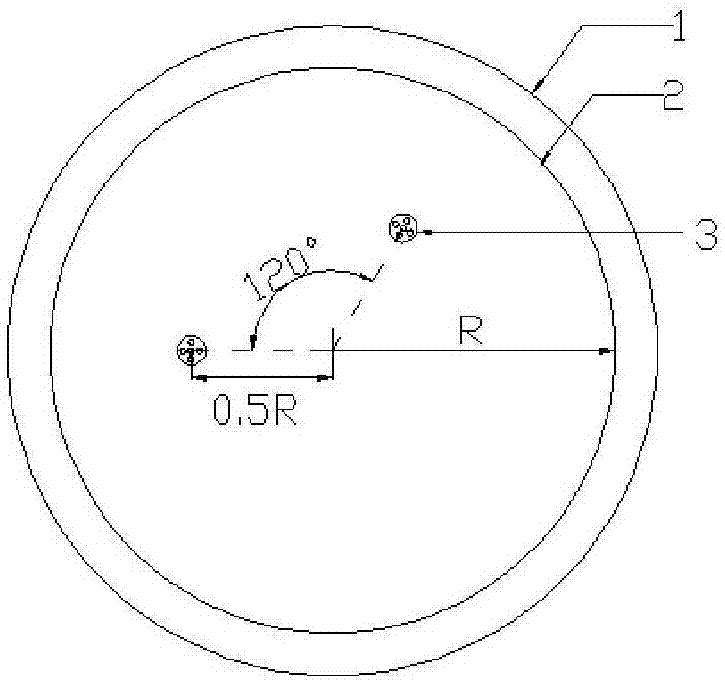

[0026] Such as figure 1 and 2 As shown, in the device for refining silicon melt outside the furnace, two gas nozzles 3 are arranged at the bottom 2 of the ladle, and the included angle θ between the center of the circles of the two nozzles 3 and the center of the ladle bottom is 120° (satisfying: 90°≤ θ≤180°); the distance 1 between the center of the two nozzles 3 and the center of the bottom of the ladle is 0.5R, and the radius r of the nozzle 3 is 0.2R, satisfying in

[0027] The application method of the device for refining silicon melt outside the furnace, its specific steps are as follows:

[0028] Step 1, set two gas nozzles 3 at the bottom of the bag 2 and continuously feed compressed air (the flow rate of the compressed air is 8m 3 / h), put the silicon melt smelted in the submerged arc furnace into the ladle (mainly including the following mass percentage components: 96% Si, 0.8% Al, 3% Ca), and release the silicon melt in the ladle The increase of SiO with a ma...

Embodiment 2

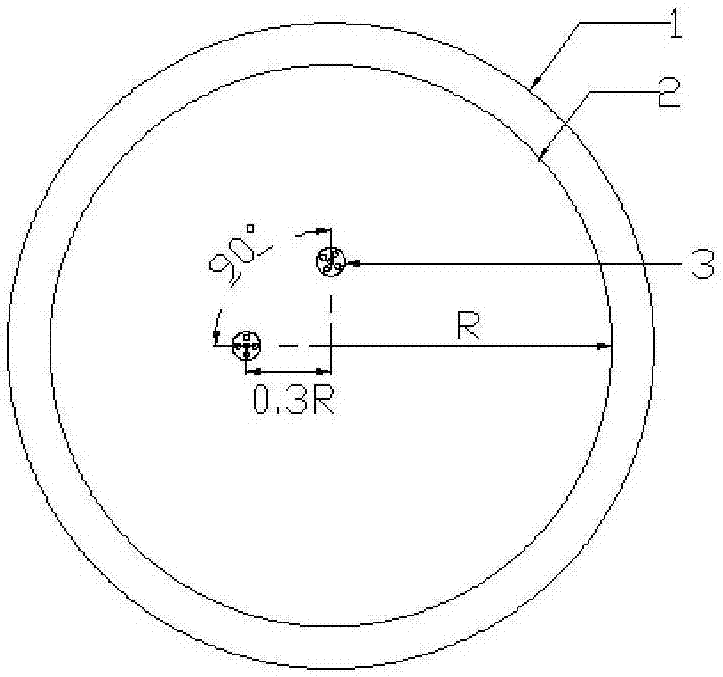

[0032] Such as image 3 As shown, in the device for refining silicon melt outside the furnace, two gas nozzles 3 are arranged at the bottom 2 of the ladle, and the included angle θ between the center of the circles of the two nozzles 3 and the center of the ladle bottom is 90° (satisfying: 90°≤ θ≤180°); the distance 1 between the center of the two nozzles 3 and the center of the bottom of the ladle is 0.3R, and the radius r of the nozzle 3 is 0.2R, satisfying in

[0033] The application method of the device for refining silicon melt outside the furnace, its specific steps are as follows:

[0034] Step 1, set two gas nozzles 3 at the bottom of the bag 2 and continuously feed compressed air (the flow rate of the compressed air is 8m 3 / h), put the silicon melt smelted in the submerged arc furnace into the ladle (mainly including the following mass percentage components: 96% Si, 0.8% Al, 3% Ca), and release the silicon melt in the ladle The increase of NaO and CaF with a ma...

Embodiment 3

[0038] Such as Figure 4 As shown in the device for refining silicon melt outside the furnace, two gas nozzles 3 are arranged at the bottom 2 of the ladle, and the included angle θ between the centers of the two nozzles 3 and the center of the ladle bottom is 180° (satisfying: 90°≤ θ≤180°); the distance 1 between the center of the two nozzles 3 and the center of the bottom of the ladle is 0.7R, and the radius r of the nozzle 3 is 0.2R, satisfying in

[0039] The application method of the device for refining silicon melt outside the furnace, its specific steps are as follows:

[0040] Step 1. Set two gas nozzles 3 at the bottom of the bag 2 to continuously feed compressed air (the flow rate of the compressed air is 12m 3 / h), put the silicon melt smelted in the submerged arc furnace into the ladle (mainly including the following mass percentage components: 96% Si, 0.8% Al, 3% Ca), and release the silicon melt in the ladle The increase, adding the mass ratio of CaO:MgO:CaF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com