A kind of technique for preparing ammonium tungstate solution

A technology of ammonium bicarbonate solution and ammonium tungstate, applied in the field of tungsten metallurgy, can solve the problems of large consumption of auxiliary materials, large consumption, complicated process, etc., and achieve the effect of eradicating waste water discharge, high utilization rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

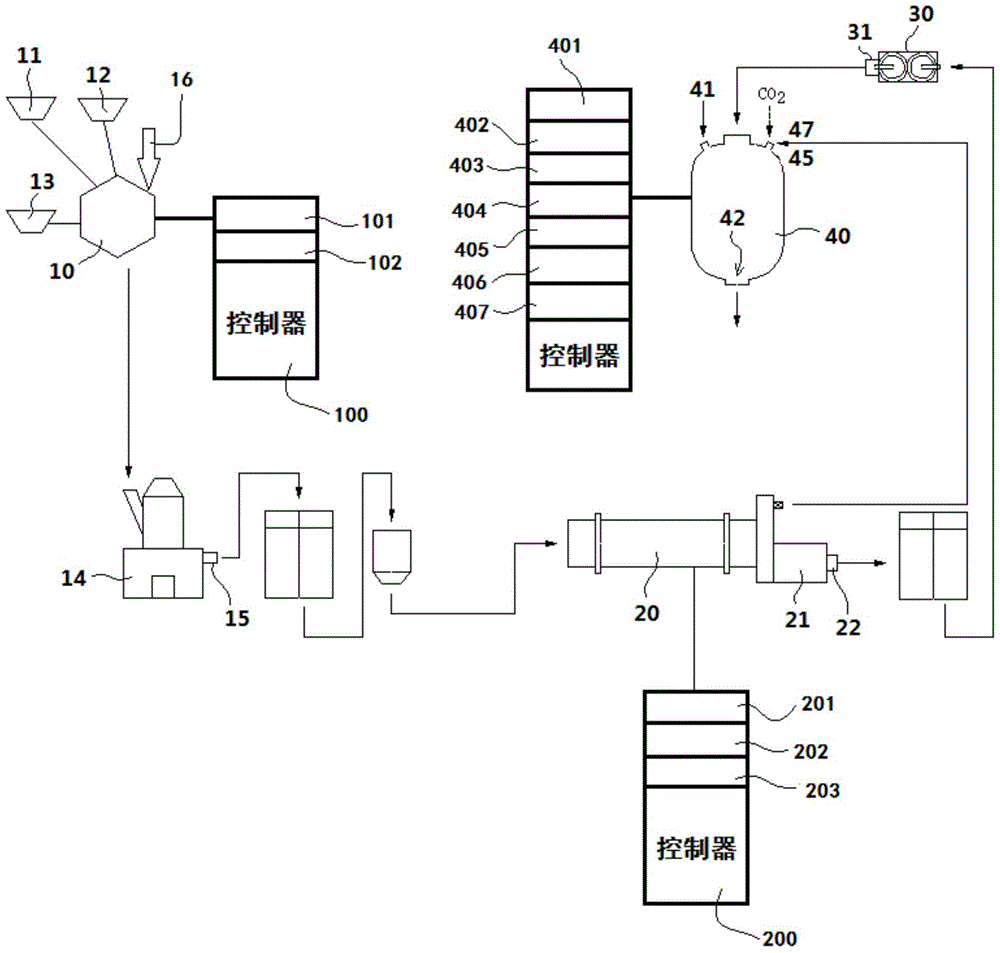

Image

Examples

Embodiment 1

[0072] Calcium carbonate (analytical pure) and tungsten trioxide (analytical pure) according to CaO / WO 3 After mixing at a molecular ratio of 3.1:1, react in a muffle furnace at 800°C for 2 hours to synthesize Ca 3 WO 6 , the synthesized Ca 3 WO 6 Pass through a 325-mesh sieve (3 WO 6 Add 50g of analytically pure ammonium carbonate to the micro-reactor together, then add 50mL of deionized water, seal it and start stirring, and leaching at 80°C for 0.5h. After the leaching is completed, the leaching slurry is vacuum filtered, and the filter cake is washed three times with deionized water. The leaching rate of tungsten is 92.90%.

Embodiment 2

[0074] Take by weighing the Ca synthesized in 5.0g embodiment 1 3 WO 6 , 0.5g of analytically pure calcium carbonate and 30g of analytically pure ammonium carbonate were added to the micro reactor together, and then 50mL of deionized water was added, the pH value was 9.7, sealed and stirred, and leached at 15°C for 10h. After the leaching is completed, the leaching slurry is vacuum filtered, and the filter cake is washed three times with deionized water. The leaching rate of tungsten is 96.16%.

Embodiment 3

[0076] Take by weighing the Ca synthesized in 5.0g embodiment 1 3 WO 6 , 0.5g of analytically pure calcium carbonate and 30g of analytically pure ammonium carbonate were added to the micro reactor together, and then 50mL of deionized water was added, sealed and stirred, and leached at 30°C for 4h. After the leaching is completed, the leaching slurry is vacuum filtered, and the filter cake is washed three times with deionized water. The leaching rate of tungsten is 98.76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com