Dynamically vulcanized polylactic acid plastic/rubber thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and vulcanized polylactic acid technology, which is applied in the field of thermoplastic elastomer materials, can solve the problems of unreasonable amount of peroxide, peculiar smell of vulcanized products, difficult biodegradation of waste, etc. knot strength, excellent impact properties, improved incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

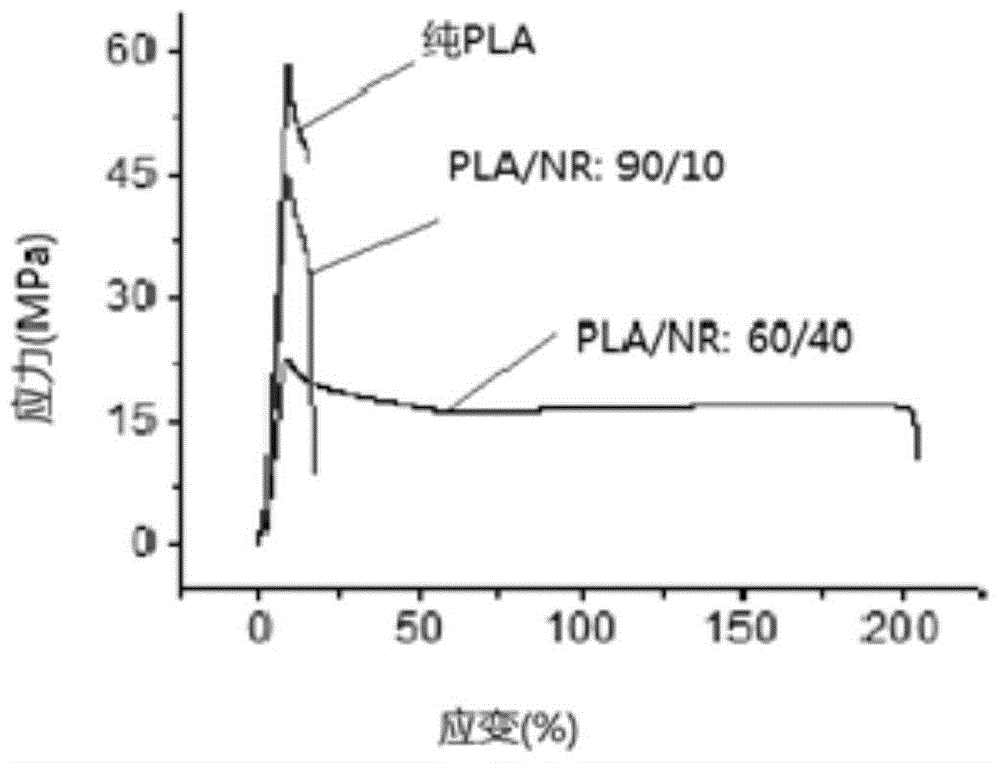

[0033]Polylactic acid was selected as the matrix resin (Zhejiang Hisun Biomaterials Co., Ltd., racemic polylactic acid (PDLLA)), and natural rubber was used as the general basic rubber (clover tree rubber Malaysia 1#, Guangzhou Rubber Industry Research Institute). Natural rubber (20 g) was first masticated on an open mill. Add polylactic acid (180g) and antioxidant 1010 (0.4g) to a Haake torque rheometer at a temperature of 160°C and a rotor speed of 60r / min. After 5 minutes, add natural rubber and interface modifier methacrylic acid Glycidyl ester (6g), after mixing for 3 minutes, add crosslinking agent bis-(tert-butylperoxyisopropyl)benzene (0.2g) and co-crosslinking agent epoxidized phenolic resin (0.2g) for dynamic vulcanization, continue Blend for 5min and discharge. The samples were crushed into fine and uniform particles with a crusher, and then injection molded into standard splines with a single-screw injection molding machine. The injection temperature of the singl...

Embodiment 2

[0035] Polylactic acid was selected as the matrix resin (Zhejiang Hisun Biomaterials Co., Ltd., racemic polylactic acid (PDLLA)), and natural rubber was used as the general basic rubber (clover tree rubber Malaysia 1#, Guangzhou Rubber Industry Research Institute). Natural rubber (40 g) was first masticated on an open mill. Add polylactic acid (160g) and antioxidant 168 (2g) to a Haake torque rheometer at a temperature of 190°C and a rotor speed of 60r / min. After 5 minutes, add natural rubber, and the interface modifier epoxidizes the natural rubber. Glue (10g), after mixing for 3 minutes, add crosslinking agent di-tert-butyl peroxide (0.6g) and co-crosslinking agent isocyanate (8.4g) for dynamic vulcanization, continue blending for 5 minutes, and discharge. The samples were crushed into fine and uniform particles with a crusher, and then injection molded into standard splines with a single-screw injection molding machine. The injection temperature of the single-screw injecti...

Embodiment 3

[0037] Polylactic acid was selected as the matrix resin (Zhejiang Hisun Biomaterials Co., Ltd., racemic polylactic acid (PDLLA)), and natural rubber was used as the general basic rubber (clover tree rubber Malaysia 1#, Guangzhou Rubber Industry Research Institute). Natural rubber (60 g) was first masticated on an open mill. Add polylactic acid (140g) and antioxidant 1076 (1.5g) to a Haake torque rheometer at a temperature of 170°C and a rotor speed of 60r / min. After 5 minutes, add the compound rubber and the interface modifier methyl Zinc acrylate (6g), after mixing for 3 minutes, add crosslinking agent dicumyl peroxide (0.9g) and auxiliary crosslinking agent triacryl cyanurate (1.1g) for dynamic vulcanization, continue blending for 5 minutes, and discharge . The samples were crushed into fine and uniform particles with a crusher, and then injection molded into standard splines with a single-screw injection molding machine. The injection temperature of the single-screw injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com