A preparation method of instant guar gum suitable for continuous mixing under low temperature conditions

A low temperature condition, guar gum technology, applied in the field of natural polymer chemistry, can solve the problems of high cost, environmental pollution, time-consuming, etc., achieve the effect of accelerating the speed of dissolution and viscosity increase, expanding the scope of application, and improving the dissolution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

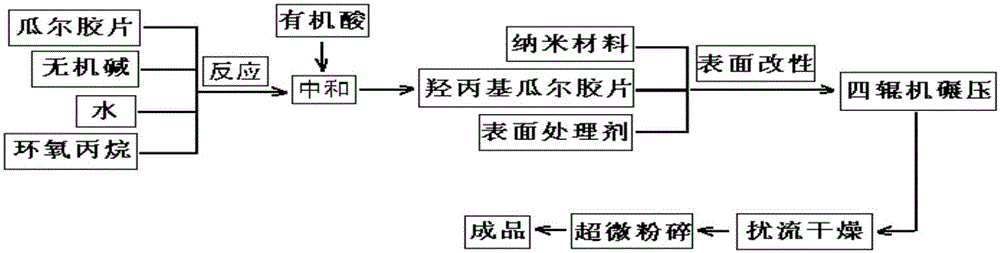

[0033] A kind of preparation method of the instant guar gum that is suitable for continuous mixing under low temperature condition, the steps are as follows:

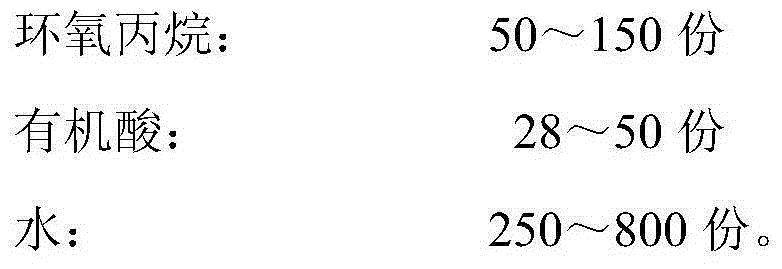

[0034] (1) Add 600 parts of guar gum film and 40 parts of solid sodium hydroxide successively into the food-grade reinforced stainless steel kneader device, and stir;

[0035] (2) Add 500 parts of water for mixing, and heat up to 65°C for 20 minutes;

[0036] (3) Add 100 parts of propylene oxide to react for 3.0 hours, then add 35 parts of acetic acid, and continue to stir for 30 minutes, so that the pH of the material is 7.5;

[0037] (4) Add 2.5 parts of nanomaterial ZnO and 60 parts of surface treatment agent fatty acid monoglyceride, continue to react at 65°C for 2.0h, and discharge;

[0038] (5) Roll the obtained materials into filaments with a four-roller, and then dry them with a turbulent flow dryer at 65°C until their water content reaches 22.3%;

[0039] ⑹ Grinding and sorting with an airflow vortex microniz...

Embodiment 2

[0045] A kind of preparation method of the instant guar gum that is suitable for continuous mixing under low temperature condition, the steps are as follows:

[0046] (1) Add 800 parts of guar gum film and 55 parts of solid sodium hydroxide successively into the food-grade reinforced stainless steel kneader device, and stir;

[0047] (2) Add 800 parts of water for mixing, and heat up to 59°C for 20 minutes;

[0048] (3) Add 150 parts of propylene oxide to react for 3.0 hours, then add 48 parts of acetic acid, and continue to stir for 30 minutes, so that the pH value of the material is 7.0;

[0049] (4) Add 3.0 parts of nanomaterial ZnO and 85 parts of surface treatment agent sorbitol monoester, continue to react at 59°C for 2.0 hours, and discharge;

[0050] (5) Roll the obtained materials into filaments with a four-roller, and then dry them with a turbulent flow dryer at 59°C until their water content reaches 26.9%;

Embodiment 3

[0057] A kind of preparation method of the instant guar gum that is suitable for continuous mixing under low temperature condition, the steps are as follows:

[0058] (1) Add 600 parts of guar gum film and 40 parts of solid potassium hydroxide successively to the food-grade reinforced stainless steel kneader device, and stir;

[0059] (2) Add 500 parts of water for mixing, and heat up to 70°C for 20 minutes;

[0060] (3) Add 100 parts of propylene oxide to react for 3.0 hours, then add 35 parts of citric acid, and continue to stir for 30 minutes, so that the pH of the material is 7.0;

[0061] (4) Add 2.5 parts of nanomaterial ZnO and 60 parts of surface treatment agent sorbitol monoester, continue to react at 65°C for 2.0h, and discharge;

[0062] (5) Roll the obtained materials into filaments with a four-roller machine, and then dry them with a turbulent flow dryer at 65°C until the water content reaches 24.0%;

[0063] ⑹ Grinding and sorting with an airflow vortex microni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com