Hemming notch cutting device and method

A curling and cutting technology, applied in the direction of positioning device, driving device, feeding device, etc., can solve the problems of high scrap rate, low efficiency, unstable product quality, etc., achieve low scrap rate, simple structure, reduce assembly and debugging the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

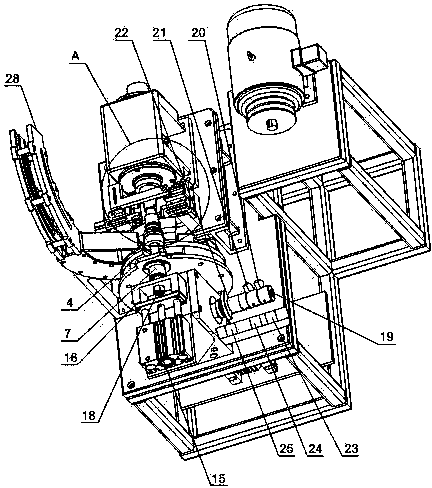

[0061] Such as Figure 1~Figure 5 As shown, the crimping and cutting device includes a driving motor 1; also includes a crimping wheel 2 and a cutter 3 arranged on both sides of the output shaft of the driving motor 1; direction, the driving structure A that drives the cutter 3 to move in the axial direction of the output shaft of the drive motor 1; also includes a workpiece positioning plate 4, and the edge of the workpiece positioning plate 4 is uniformly provided with a plurality of through holes 5; also includes a cam The splitter 6, the output shaft of the cam splitter 6 is connected to the workpiece positioning plate 4, and the cam splitter 6 is configured so that the input shaft rotates one revolution, and the output shaft drives the workpiece positioning plate 4 to rotate at a certain angle to make the workpiece positioning plate 4 rotate. One is facing the output shaft of the motor 1 through the hole 5; it also includes the ejector rod 7, and the ejector rod 7 is faci...

Embodiment 2

[0069] Such as figure 2 with Figure 5 As shown, this embodiment further describes the cam control device on the basis of embodiment 1. The cam control device includes a control shaft 19 connected to the output shaft of the cam splitter 6, and is arranged on the control shaft 19. The first control cam 20, the second control cam 21 and the third control cam 22, the first proximity sensor 23 and the second proximity sensor corresponding to the first control cam 20, the second control cam 21 and the third control cam 22 respectively 24 and the third proximity sensor 25, the first electric control valve, the second electric control valve and the third electric control valve connected with the first proximity sensor 23, the second proximity sensor 24 and the third proximity sensor 25 respectively, the first electric control valve The control valve is connected with the drive structure A, and the second electric control valve and the third electric control valve are connected with...

Embodiment 3

[0081] Such as Figure 1~Figure 5 As shown, this embodiment further describes the driving structure A on the basis of the second embodiment.

[0082] Described driving structure A comprises cylinder A8, crimping wheel fixed body 9, connecting body 10 and cutter fixed body 11, and the output shaft of cylinder A8 is perpendicular to the output shaft of described drive motor 1, and the output shaft of cylinder A8 and curling The wheel fixed body 9 is connected, and the two ends of the connecting body 10 are connected with the crimping wheel fixed body 9 and the cutter fixed body 11 respectively, and the crimping wheel 2 is fixed on the crimping wheel fixed body 9, and the cutter 3 is fixed On the cutter fixed body 11;

[0083] The drive structure A also includes a sliding fixed block 12, on which the cutter fixed body 11 is slidably arranged, and the sliding direction of the cutter fixed body 11 is parallel to the output shaft of the drive motor 1;

[0084]A chute 13 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com