Method for controlling detonator zone during explosion cladding of multilayer thick zirconium/titanium/steel composite plate

A control method and composite plate technology, which is applied in the field of explosive compounding, can solve the problems that the zirconium plate cannot quickly reach the range of the explosive welding window, and the detonation point is not combined, and achieve the effects of good quality, convenient implementation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1. Prepare a titanium / steel composite plate of 1050mm×3550mm×22mm (2mm / 20mm) by explosive composite welding, and conduct heat treatment, leveling and grinding on the prepared titanium / steel composite plate in sequence, so that the unevenness is not greater than 5mm / m , the titanium / steel composite plate 1 with the surface roughness Ra of the titanium layer being 0.5 μm; the grade of the titanium plate in the titanium / steel composite plate is TA1, and the steel plate is a container plate Q345R; the temperature of the heat treatment is 500° C. The time is 5h;

[0024] Step 2. Grinding the zirconium plate with a size of 1100mm×3600mm×10mm to obtain a composite zirconium plate 2 with a roughness Ra of 0.5 μm on the side contacting the titanium / steel composite plate; the grade of the zirconium plate is ASTM B551R60702 ;

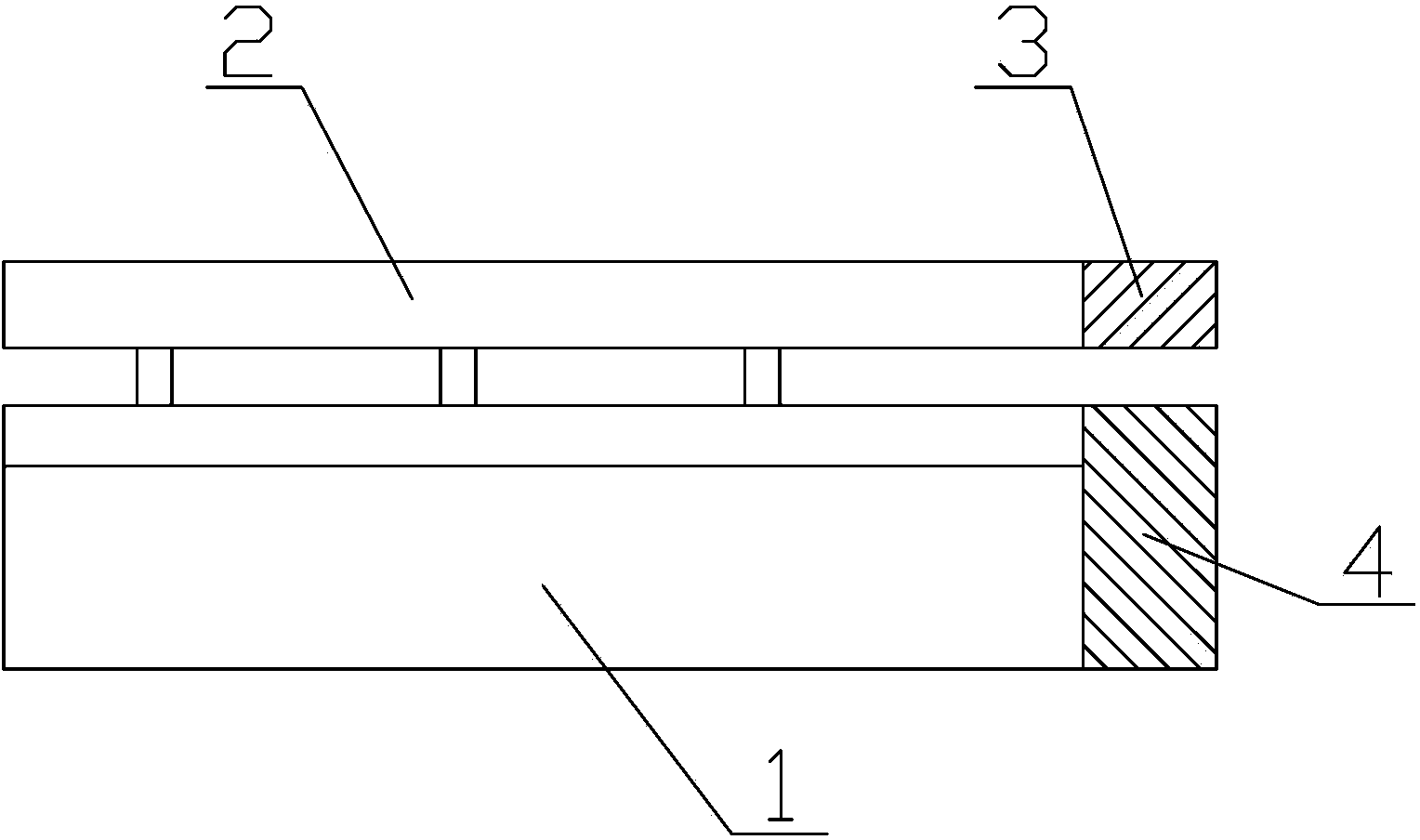

[0025] Step 3. Weld the carbon steel forging steel block 4 with a size specification of 200mm×300mm×22mm in the geometric middle of one side of the l...

Embodiment 2

[0030] This embodiment is the same as embodiment 1, wherein the difference is: the titanium block is TA1, TA2, TA9, ASTM B265-Gr.1, ASTM B265-Gr.2, ASTM B265Gr7, ASTM B265Gr11 or ASTM B265Gr16; The above-mentioned steel block is a steel block with the grade of Q345R, Q235B or ASMESA516Gr.70, or a stainless steel forging.

[0031] The thick clad zirconium / titanium / steel clad plate produced in this example is of good quality, with a bonding rate of 100% and a shear strength of not less than 180MPa, which meets the requirements of ASTM B898-2005A grade and can meet the requirements of various large industrial equipment and components on thick clad plates. Manufacture requirements for ply zirconium / titanium / steel composite panels.

Embodiment 3

[0033] Step 1. Prepare a titanium / steel composite plate of 3550mm×3550mm×154mm (4mm / 150mm) by explosive hybrid welding, and then heat-treat, level and polish the prepared titanium / steel composite plate in order to obtain an unevenness not greater than 4mm / m , the roughness Ra of the titanium layer surface is a titanium / steel composite plate 1 of 10 μm; the grade of the titanium plate in the titanium / steel composite plate is TA9, and the steel plate is Q235B; the temperature of the heat treatment is 500°C, and the holding time is 5h ;

[0034] Step 2. Grinding the zirconium plate with a size of 3600mm×3600mm×7mm to obtain a composite zirconium plate 2 with a roughness Ra of 25 μm on the side contacting the titanium / steel composite plate; the grade of the zirconium plate is ASTM B551R60702;

[0035] Step 3. The geometrical middle part of the long side of the titanium / steel composite plate 1 described in step 1 is welded with a size specification of 30mm×60mm×154mm, and the steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com