Highly-dispersed catalyst for hydrogen peroxide synthesis and preparation method thereof

A technology of catalyst and hydrogen peroxide, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve highly toxic organotin compounds, not applicable Production and other problems, to improve catalyst activity and overcome the effect of large crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Catalyst preparation

[0037] 1) Weigh 2.0gAl 2 o 3 , 100ml ethylene glycol, 25ml isopropanol, 0.1gPVP, 0.24gNaOH in a three-necked flask, pass into N 2 , stirred for 1h.

[0038] 2) Add 0.043gPd(NO 3 ) 2 , heated to 110°C in an oil bath, and refluxed for 3h.

[0039] 3) After the mixture is cooled to room temperature, add 0.5M HNO 3 To pH = 3, stirred for 10h.

[0040] 4) suction filtration, the obtained solid was washed with ethanol and deionized water until neutral.

[0041] 5) dry. The obtained solid was dried at 110° C. for 12 h to obtain catalyst A.

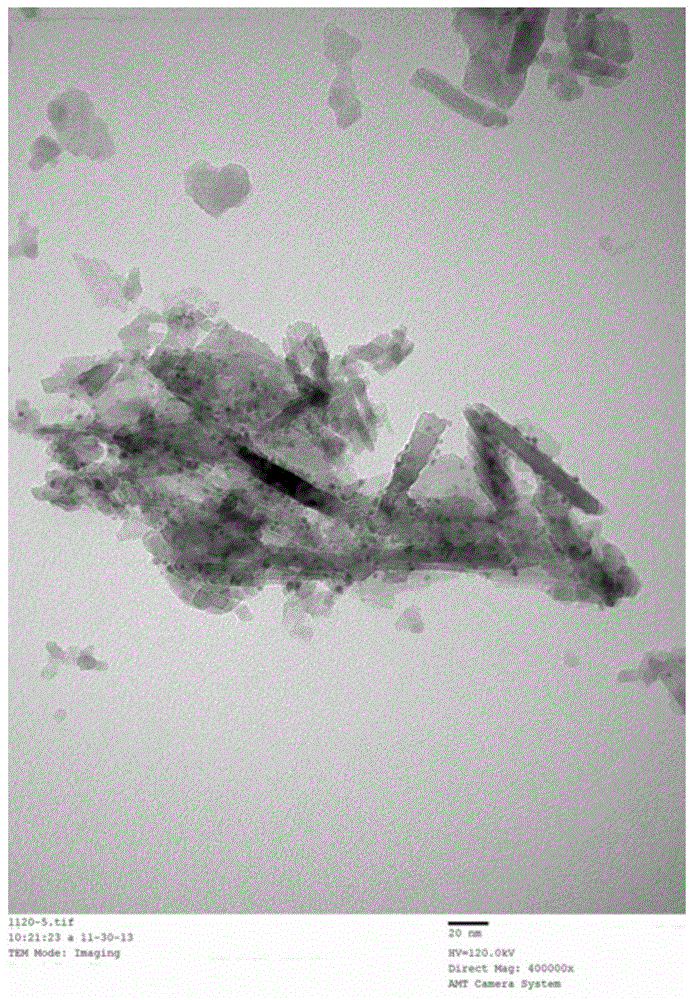

[0042] The CO chemical adsorption pulse test shows that the Pd dispersion is 53.4%, and the particle size of Pd particles is 2.8nm according to TEM. The TEM photo is shown in figure 1 , The evaluation results of catalyst hydrogenation performance are shown in Table 1.

Embodiment 2

[0044] Catalyst preparation

[0045] 1) Weigh 2.0gMg-Al hydrotalcite, 100ml methanol, 25ml isopropanol, 0.04gPVP, 0.12gNaOH in a flat-bottomed three-necked flask, and pass into N 2 , stirred for 1h.

[0046] 2) Add 0.0086gPd(NO 3 ) 2 , Stir evenly and heat in microwave for 1min with a power of 900W.

[0047] 3) After the mixture is cooled to room temperature, add 0.5M HNO 3 To pH = 3, stirred for 10h.

[0048] 4) suction filtration, the obtained solid was washed with ethanol and deionized water until neutral.

[0049] 5) dry. The obtained solid was dried at 70°C for 12 hours to obtain catalyst B.

[0050] The CO chemisorption pulse test shows that the Pd dispersion is 13.7%. The hydrogenation performance evaluation results of the catalyst are shown in Table 1.

Embodiment 3

[0052] Catalyst preparation

[0053] 1) Weigh 2.0g SiO2 2 , 100ml methanol, 0.3gCTAB, 0.24gNaOH in a three-necked flask, N 2 , stir.

[0054] 2) Add 0.033PdCl to the flask 2 , heated to 50°C in an oil bath, and refluxed for 12h.

[0055] 3) After the mixture is cooled to room temperature, add 0.5M HNO 3 To pH = 3, stirred for 10h.

[0056] 4) suction filtration, the obtained solid was washed with ethanol and deionized water until neutral.

[0057] 5) dry. The obtained solid was vacuum-dried at 50°C for 12 hours to obtain catalyst C.

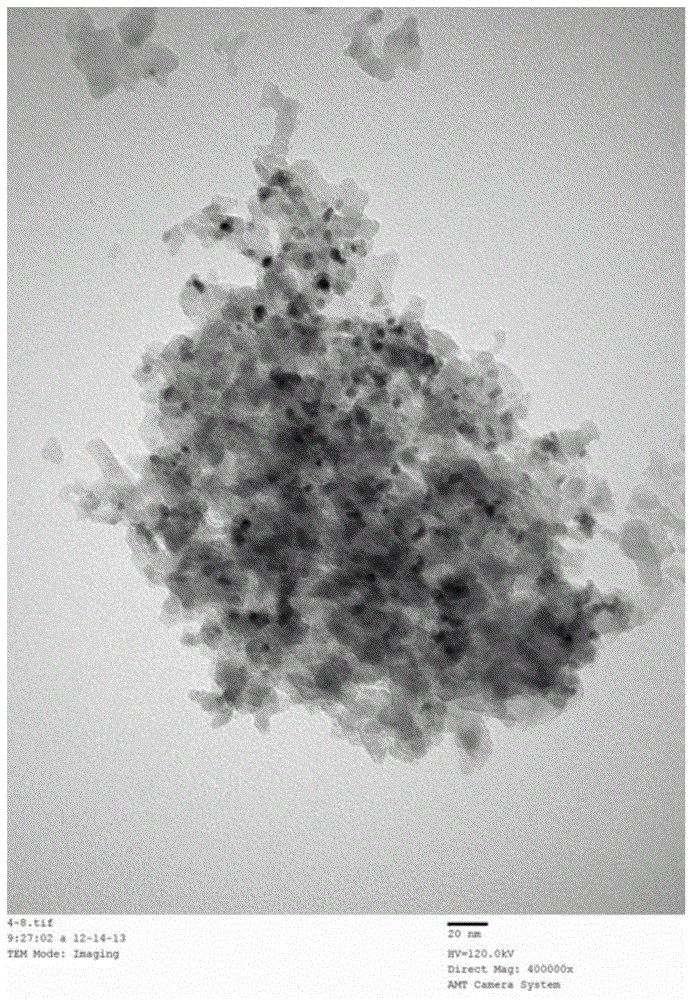

[0058] The CO chemical adsorption pulse test shows that the Pd dispersion is 33.9%, and the particle size of Pd particles is 3.7nm according to TEM. The TEM photo is shown in figure 2 , Catalyst hydrogenation evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com