Method for preparing nano copper/carbon nano tube composite powder by liquid phase method

A technology of carbon nanotube composite and carbon nanotube, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult control of nano-copper particles, complicated preparation methods, and high cost, and achieve Low cost, simple process, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

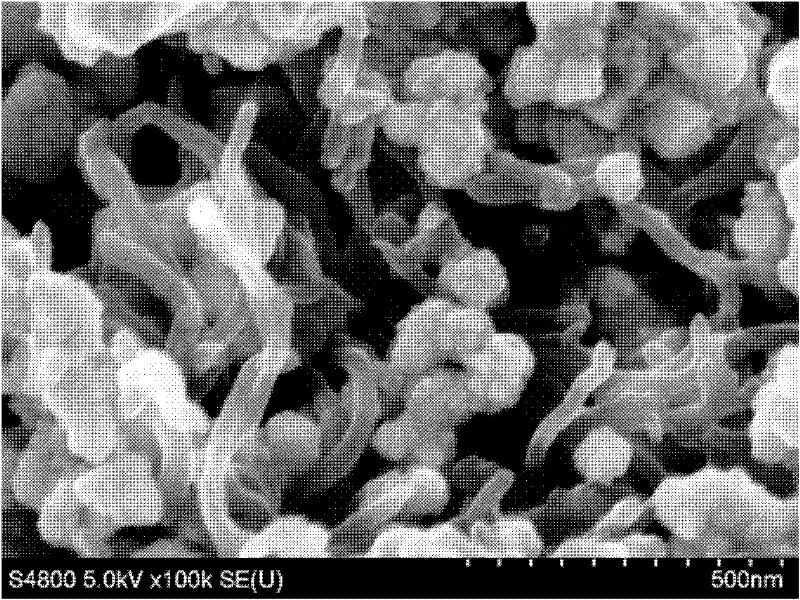

[0016] Embodiment 1: This embodiment is a method for preparing nano-copper / carbon nanotube composite powder by liquid phase method, which is realized through the following steps: 1. Carbon nanotubes after acidification treatment and polyvinylpyrrolidone (PVP) Add copper sulfate solution, ultrasonically mix to obtain mixed solution A, then adjust the pH value of mixed solution A to 10-12, then add hydrazine hydrate solution, and mix to obtain mixed solution B, wherein the mass of carbon nanotubes after acidification treatment and sulfuric acid The ratio of copper molar weight is 1~3g: 0.1mol, the concentration of copper sulfate solution is 0.1~0.5mol / L, the quality of polyvinylpyrrolidone is 3%~10% of copper sulfate quality, the mol ratio of hydrazine hydrate and copper sulfate is 10~20:1; 2. Stir and react the mixed solution B obtained in step 1 at 60~80°C for 2~6h, then cool to room temperature, filter the reaction system to obtain powder, and then wash the powder until medium...

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the acidified carbon nanotubes used in step 1 are obtained through the following acidification treatment: carbon nanotubes are added with a mass concentration of 10% to 30%. In nitric acid, under the condition of 100-120°C, stir and heat to reflux for 3-5h, then cool to room temperature, wash the carbon nanotubes until the filtrate is neutral, and then vacuum-dry at 50°C for 24-48h to obtain acidified Carbon nanotubes, that is, the acidification treatment of carbon nanometers is completed. Other steps and parameters are the same as those in Embodiment 1.

[0020] In this embodiment, the carbon nanotubes may be submerged in nitric acid.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the carbon nanotubes after the acidification treatment used in step one are obtained by the following acidification treatment: the carbon nanotubes are added to nitric acid with a mass concentration of 20%, Under the condition of 110°C, stir and heat to reflux for 4 hours, then cool to room temperature, wash the carbon nanotubes until the filtrate is neutral, and then vacuum-dry them at 50°C for 24 hours to obtain carbon nanotubes after acidification treatment, that is, carbon nanotubes are completed. Acid treatment. Other steps and parameters are the same as those in Embodiment 1.

[0022] In this embodiment, the carbon nanotubes may be submerged in nitric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com