Electrochemical desulphurization method and application of intermediate product

An electrochemical, sulfur dioxide technology, applied in chemical instruments and methods, applications, inorganic chemistry, etc., can solve problems such as secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

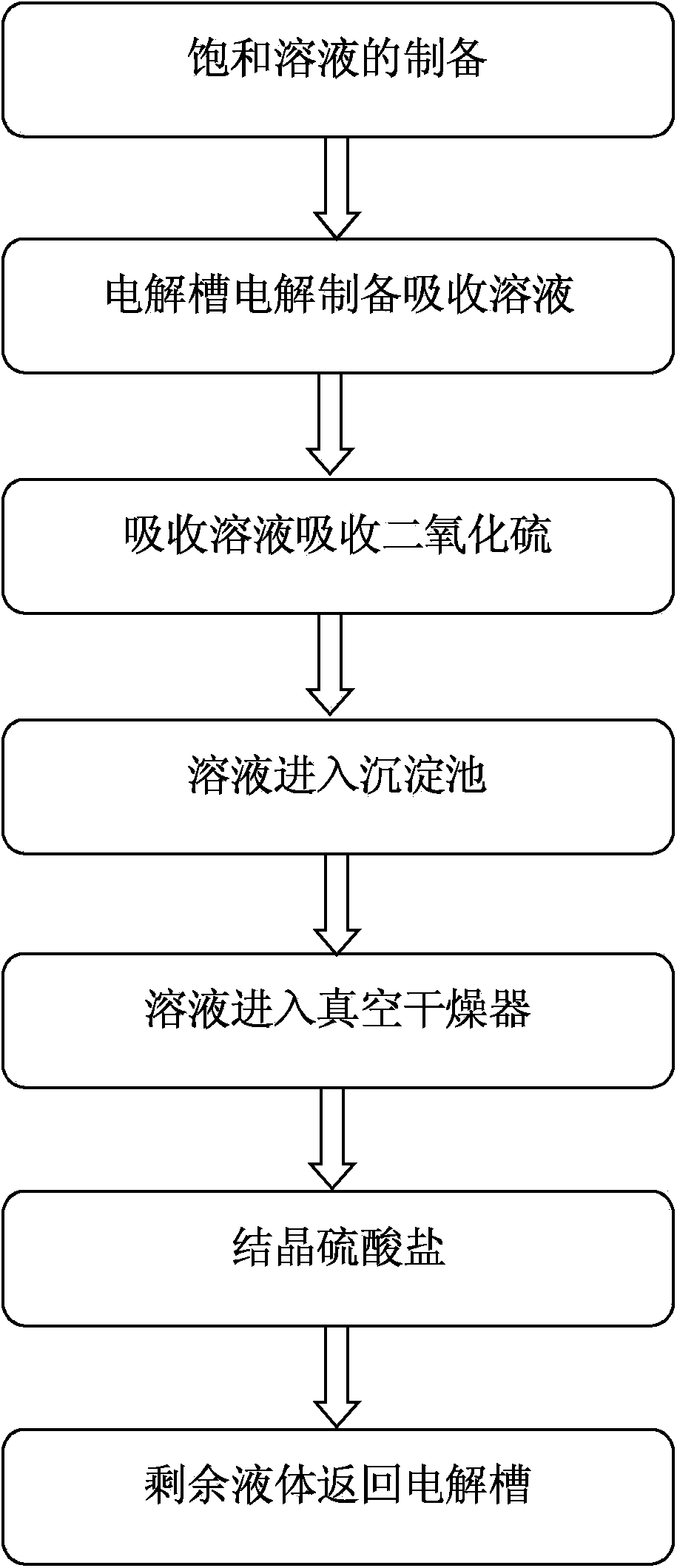

[0028] Such as figure 1 Shown is the process flow diagram of the electrochemical desulfurization method of the present invention, and the method steps of the present invention are as follows:

[0029] 1. Prepare a saturated solution of sodium iodide;

[0030] 2. Feed the saturated solution of sodium iodide into the electrolytic cell, perform electrolysis under the effect of a direct current electric field, and prepare by electrolysis a sodium hydroxide alkaline solution containing 10% elemental iodine, i.e. an absorption solution;

[0031] 3. Spray the absorption solution after electrolysis into the sulfur dioxide absorption tower, control the molar ratio of sodium hydroxide in the absorption solution to sulfur dioxide in the absorption tower to 1:1, the sulfur dioxide in the absorption tower is absorbed and oxidized to form a sodium sulfate solution ;

[0032] 4. Control the pH value of the absorption solution after absorption to be 6.5, pass the absorption solution after t...

Embodiment 2

[0035] 1. Prepare a saturated solution of potassium bromide;

[0036] 2. Pass potassium bromide saturated solution in the electrolyzer, carry out electrolysis under the effect of DC electric field, electrolysis is prepared into the potassium hydroxide alkaline solution containing 5% elemental bromine, i.e. absorption solution;

[0037] 3. Spray the electrolyzed absorption solution into the sulfur dioxide absorption tower, control the molar ratio of potassium hydroxide in the absorption solution to sulfur dioxide in the absorption tower to 1:1.1, and the sulfur dioxide in the absorption tower is absorbed and oxidized to form potassium sulfate solution ;

[0038] 4. Control the pH value of the absorption solution after absorption to be 6.8, pass the absorption solution after the absorption into the sedimentation tank, separate the solid dust therein, and pass the supernatant liquid generated into the vacuum dryer, and the potassium sulfate crystallization in the absorption solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com