Low-lying corrosion-resistant alloyed anti-corrosion and thermal insulation pipeline and its processing technology

A technology of corrosion-resistant alloys and heat-insulating pipelines, which is applied in the direction of heat insulation protection pipelines, metal material coating technology, pipeline anti-corrosion/rust protection, etc., which can solve over-protection, high maintenance power supply costs, and reduced protection effect at points away from anodes To achieve the effect of ensuring the bonding force, eliminating the cathode shielding phenomenon, and the structure of the passivation film is stable and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

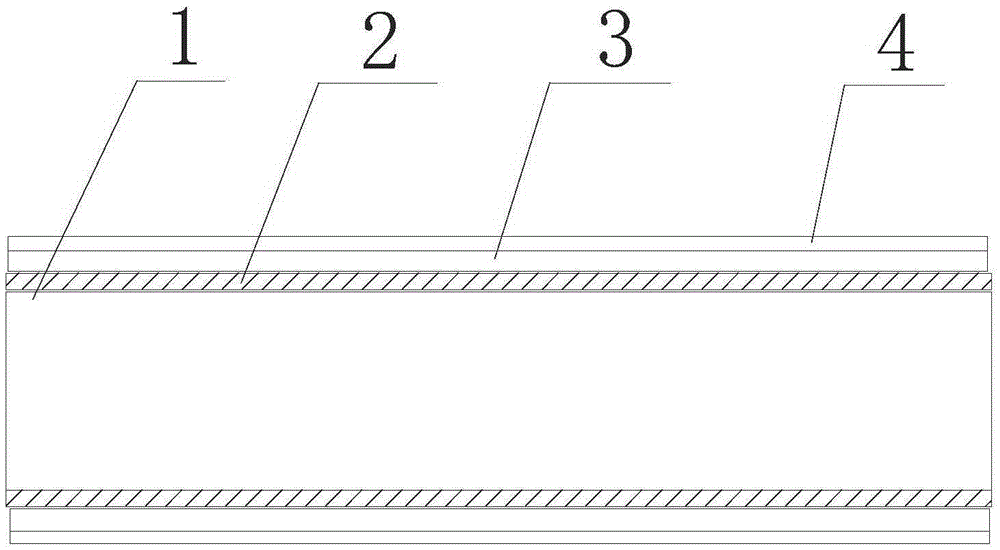

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] Depend on figure 1 As shown, a low-lying corrosion-resistant alloyed anti-corrosion and heat-preservation pipeline includes a steel pipe 1, a multi-element alloy corrosion-resistant layer 2, a polyurethane heat-insulating layer 3, and a polyethylene protective layer 4. It is characterized in that: the outer wall of the steel pipe 1 is covered with a multi-element alloy corrosion-resistant layer 2. The multi-element alloy corrosion-resistant layer 2 is covered with a polyurethane insulation layer 3, and the polyethylene protective layer 4 is covered outside the polyurethane insulation layer 3. The thickness of the multi-element corrosion-resistant alloy layer 2 is 200 μm-300 μm, which is a multi-element alloy including Zn, Al, and Ni Composite coating, the polyurethane insulation layer 3 has a thickness of 25mm-30mm, and is a light-weight, high-strength insulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com