Method for tucking an end of a weft thread into a selvedge of a fabric, and pneumatic tuck-in device

A fabric and weft thread technology, applied in the field of pneumatic folding devices, can solve problems such as the complexity of driving equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

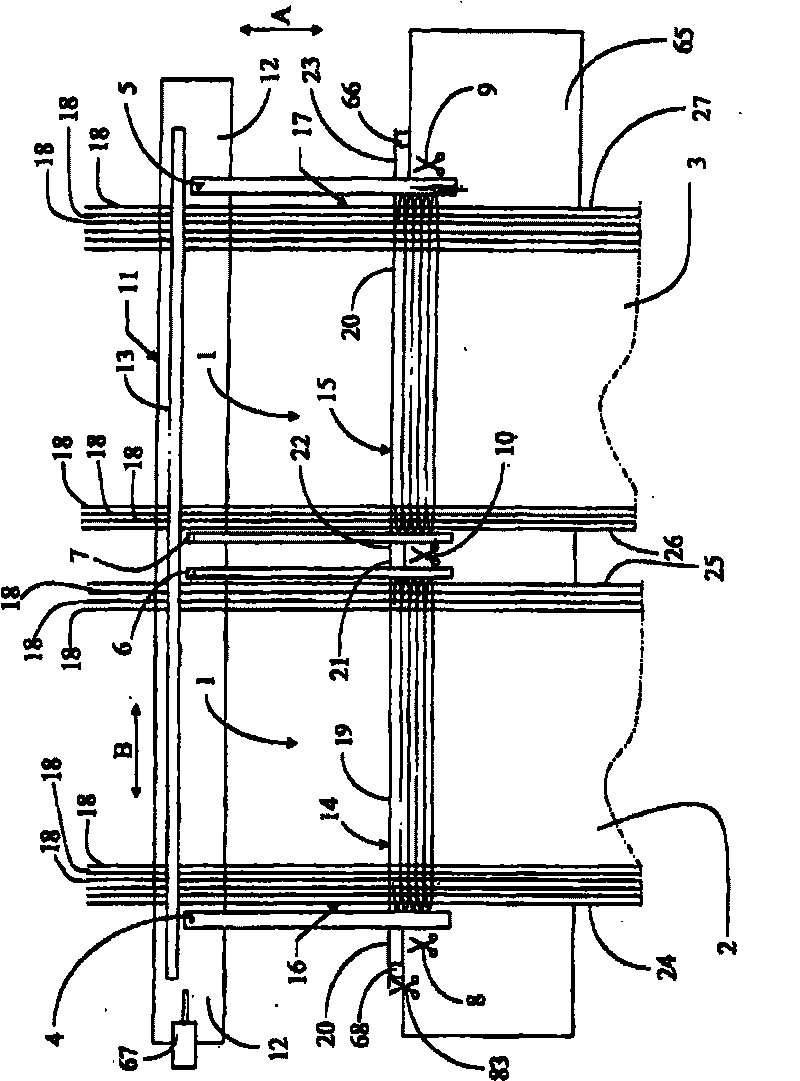

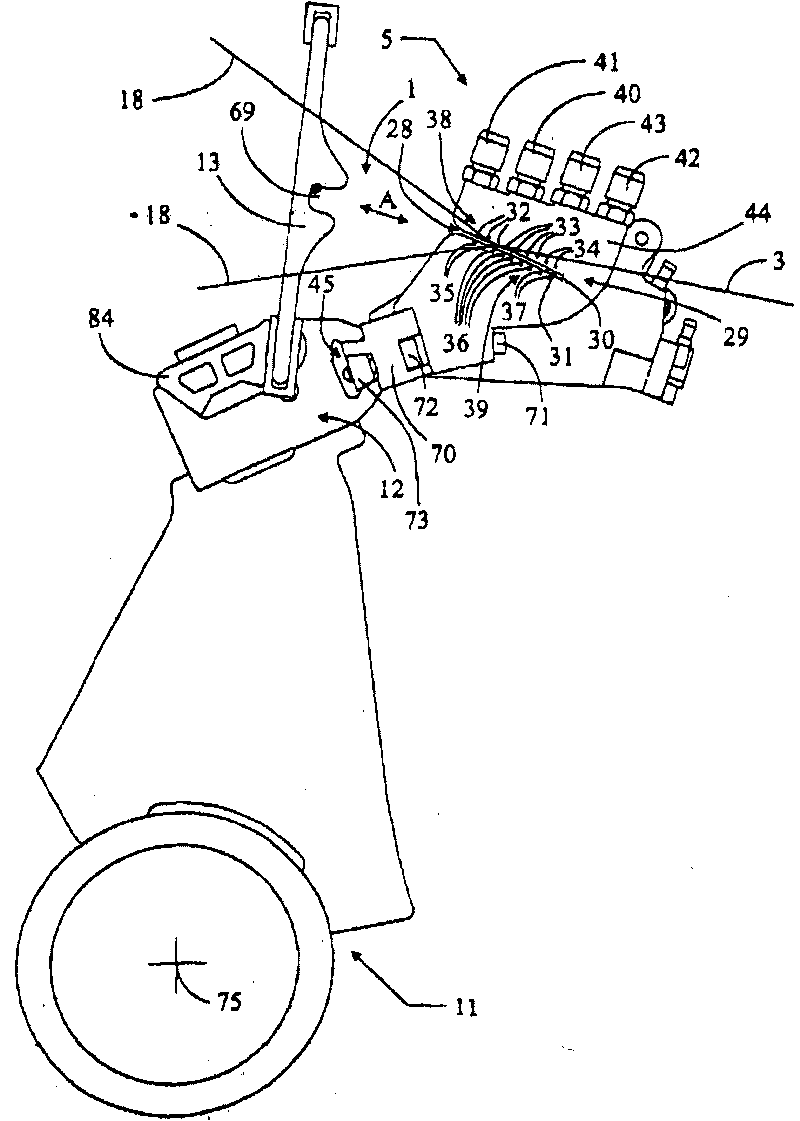

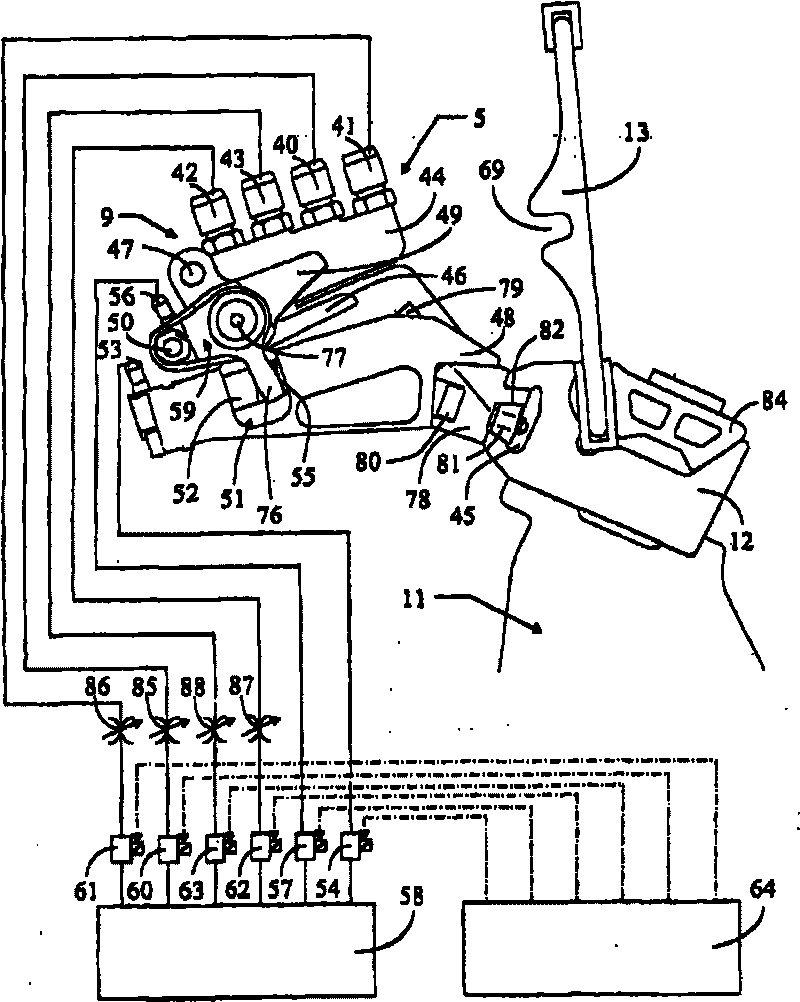

[0026] exist figure 1 In the loom shown, two pieces of fabric 2, 3 are woven next to each other. The figure shows four pneumatic tuck-in devices 4 to 7 according to the invention, more specifically one tuck-in device 4 is arranged near the insertion side 16 of the shed 1 and one tuck-in device 5 is arranged at the shed 1 Near the opposite side 17 of , the two tuck-in devices 6 and 7 are arranged between the fabrics 2, 3 adjacent to each other. A cutting device 8 is added to the tuck-in device 4 , a cutting device 9 is added to the tuck-in device 5 and a common cutting device 10 is added to the tuck-in devices 6 and 7 . The weaving machine also comprises a sley 11 comprising a sley profile 12 to which a reed 13 is attached. In this case, the tuck-in devices 4 to 7 are attached to the sley profile 12 . In this case, the cutting devices 8 to 10 are also attached to the sley profile 12 . In order to allow the insertion of weft threads, the shed 1 is formed in a known manner us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com