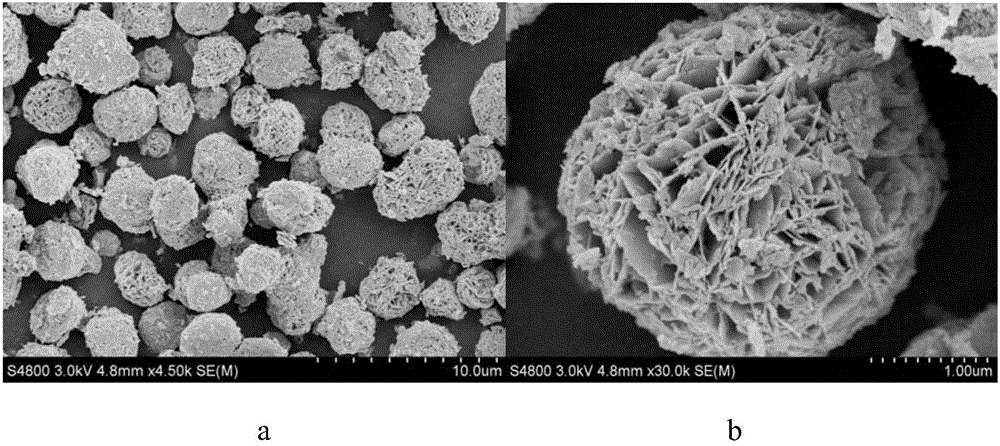

A kind of eu loaded bi2wo6 porous microsphere with good dispersibility and its preparation method and application

A porous microsphere, good dispersibility technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Uneven heat distribution, slow heating rate and other problems, to achieve the effects of uniform and stable morphology, short preparation cycle and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Eu loading Bi with good dispersion 2 WO 6 A method for preparing porous microspheres, comprising the following steps:

[0031] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O was put into a beaker, and a certain amount of Eu(NO 3 ) 3 ·6H 2 O is added to the beaker, wherein the amount of Eu added x=4%, x=n Eu / (n Bi +n Eu )×100%, n Bi and n Eu are the molar amounts of Bi and Eu, respectively;

[0032] Step 2: Measure deionized water into the beaker, fully stir at room temperature for 20 minutes, and prepare a mixed solution, wherein Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.2mol / L, Na 2 WO 4 2H 2 The concentration of O is 0.1mol / L, and then ultrasonically disperse the mixed solution for 40 minutes, so that the raw materials are fully dissolved and dispersed evenly, and the precursor solution is obtained;

[0033] Step 3: Move the precursor liquid into the microwave hydrothermal reactor lined with polytetrafluoroethylene, control the fillin...

Embodiment 2

[0037] Eu loading Bi with good dispersion 2 WO 6 A method for preparing porous microspheres, comprising the following steps:

[0038] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O was put into a beaker, and a certain amount of Eu(NO 3 ) 3 ·6H 2 O is added to the beaker, where the amount of Eu added x=10%, x=n Eu / (n Bi +n Eu )×100%, n Bi and n Eu are the molar amounts of Bi and Eu, respectively;

[0039] Step 2: Measure deionized water and add it to the beaker, fully stir for 40min at room temperature, and prepare a mixed solution, in which Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.6mol / L, Na 2 WO 4 2H 2 The concentration of O is 0.3mol / L, and then the mixed solution is ultrasonically dispersed for 50 minutes, so that the raw materials are fully dissolved and dispersed evenly, and the precursor solution is obtained;

[0040] Step 3: Move the precursor solution into the microwave hydrothermal reactor lined with polytetrafluoroethylene, control ...

Embodiment 3

[0044] Eu loading Bi with good dispersion 2 WO 6 A method for preparing porous microspheres, comprising the following steps:

[0045] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O was put into a beaker, and a certain amount of Eu(NO 3 ) 3 ·6H 2 O is added to the beaker, wherein the amount of Eu added x=15%, x=n Eu / (n Bi +n Eu )×100%, n Bi and n Eu are the molar amounts of Bi and Eu, respectively;

[0046] Step 2: Measure deionized water and add it to the beaker, fully stir it at room temperature for 25 minutes, and prepare a mixed solution, in which Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.4mol / L, Na 2 WO 4 2H 2 The concentration of O is 0.2mol / L, and then the mixed solution is ultrasonically dispersed for 60 minutes, so that the raw materials are fully dissolved and dispersed evenly, and the precursor solution is obtained;

[0047] Step 3: Move the precursor liquid into the microwave hydrothermal reactor lined with polytetrafluoroethylene, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com