A kind of abalone shell pearl layer powder and processing method thereof

A technology of pearl layer powder and abalone shell, which is applied in the direction of digestive system, metabolic diseases, antipyretics, etc., can solve the problems of lower quality and efficacy, low cost of raw materials, high cost, etc., to ensure quality and effectiveness, reduce Production cost, safe and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

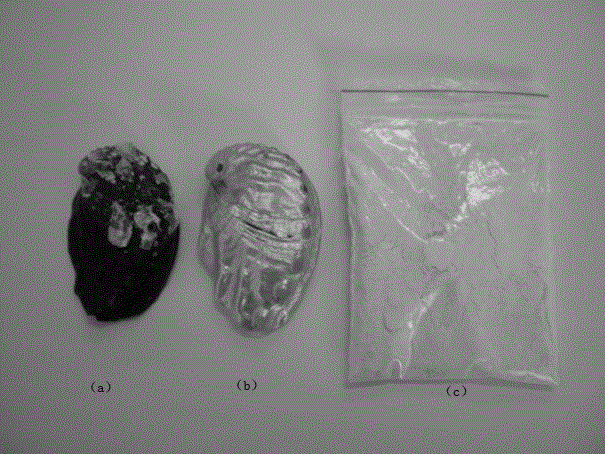

Image

Examples

Embodiment 1

[0040] 21.2 kg of variegated abalone shells were placed in an extraction tank, and 10 mol / L hydrochloric acid solution with a weight ratio of 3 times was added, and acid-washed at room temperature to remove non-aragonite-structured calcium carbonate, cuticle, prism layer, outer shell, etc. Impurities such as verruca and algae pigments, after 15 minutes, when no carbon dioxide bubbles are generated, let stand for 5 minutes and then separate the solid and liquid, wash the separated pearl layer with water until the washing liquid is neutral, After drying and then drying, the nacre raw material is obtained, which has the original pearl luster of the inner layer of the variegated abalone shell, and the shell shape integrity rate is 90.8%, retaining the original natural minerals, keratin and trace elements of the nacre . The pearl layer is further baked at a high temperature of 120-150°C. When the surface is yellow and there is a crackling sound, it is quickly cooled to 60-70°C, mec...

Embodiment 2

[0042] 13.9 kg of wrinkled abalone shells were placed in an extraction tank, and 6 mol / L nitric acid solution with a weight ratio of 5 times was added, and acid-washed at 45°C to remove non-aragonite calcium carbonate, cuticle, prism layer, Impurities such as warts and algae pigments in the outer layer, when no carbon dioxide bubbles are generated, let stand for 12 minutes before solid-liquid separation, and wash the separated pearl layer with water until the washing liquid is neutral, then drain , put it in a ball mill cylinder, add appropriate amount of distilled water, ball mill it into powder, put it in a square pan and spread it evenly, bake it at 110-120°C until dry, cool it to room temperature, put it in a vibrating kneader to vibrate and pulverize, and collect it by classification. Ultrafine nacre powder with a fineness of 600 mesh can be obtained. After testing, the nacre aragonite-type calcium carbonate content is 94.8%, and the impurity removal rate is 92.5%.

Embodiment 3

[0044] 6.1 kg of Australian abalone shells are placed in the extraction tank, using 10 times the weight ratio of acetic acid aqueous solution, and at no lower than room temperature, reflux to remove non-aragonite calcium carbonate, cuticle, prismatic layer, and outer warts in the abalone shell During the extraction process, the concentration of hydrogen ions in the system should not be lower than 2 mol / L. When no more carbon dioxide bubbles are generated, the solid-liquid separation will be allowed to stand for 20 minutes, and the separated nacre After washing with water until the washing liquid is neutral, it is dried, crushed by high temperature and high pressure, and then crushed in a jet mill and collected by classification to obtain superfine nacre powder with a fineness of 1000 mesh. After testing, the nacre aragonite-type calcium carbonate content is 96.2%, and the impurity removal rate is 91.1%. The superfine nacre powder can be further processed into nano nacre powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com