Method for separating and recycling graphite and copper sheets in negative pole materials of waste lithium ion batteries

A lithium-ion battery and negative electrode material technology, which is applied in the field of separation and recovery of graphite and copper flakes in waste lithium-ion battery negative electrode materials, can solve the problems of high energy consumption in the purification process, low graphite ore grade, and low graphite recovery rate. Achieve the effects of high recovery rate and product added value, low energy consumption, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

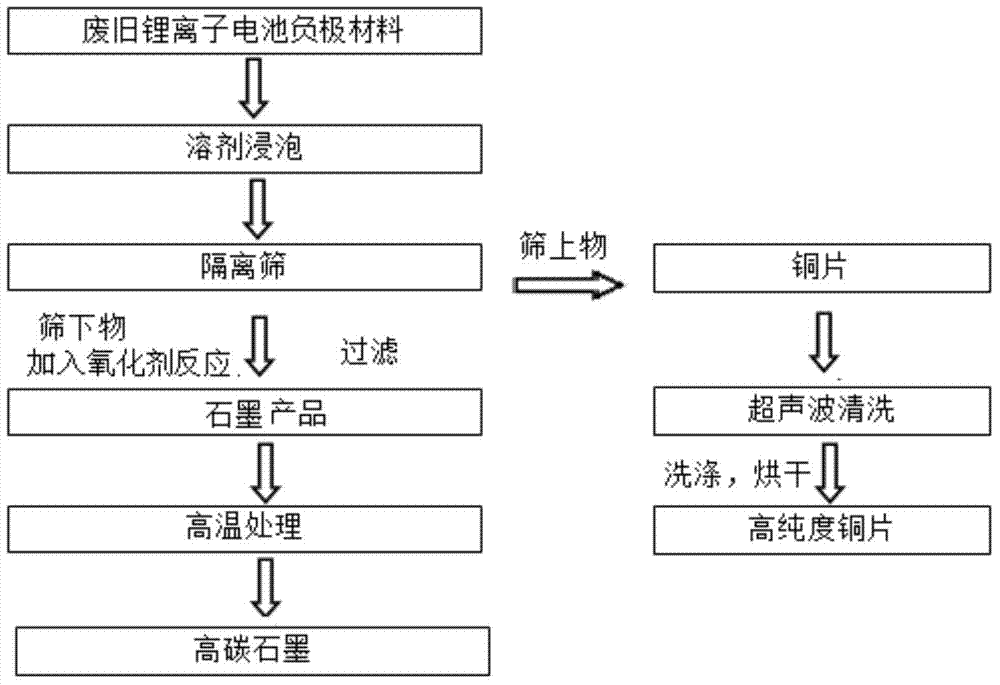

Method used

Image

Examples

Embodiment 1

[0032] Soak a 1kg waste lithium battery negative electrode piece in 10L0.2mol / L dilute sulfuric acid for 10 minutes, then use a speed-regulating oscillator and a submersible pump to create a tumbling water flow in the container to wash away the negative electrode material. The role is to make the separation of graphite and copper sheets more rapid and thorough. The speed of the speed-adjusting oscillator is 240r / min, the power of the submersible pump is 60w, the working time is 10min, and then stand for 5min. Sieve and sieve to obtain copper flakes on the sieve and graphite on the sieve.

[0033] After taking out the copper sheet with dilute sulfuric acid attached to the surface, soak it in an ultrasonic cleaning machine for 2 minutes, then filter it out and place it in a blast drying oven, and dry it to a constant weight at 50°C to obtain a 315g high Pure copper sheet.

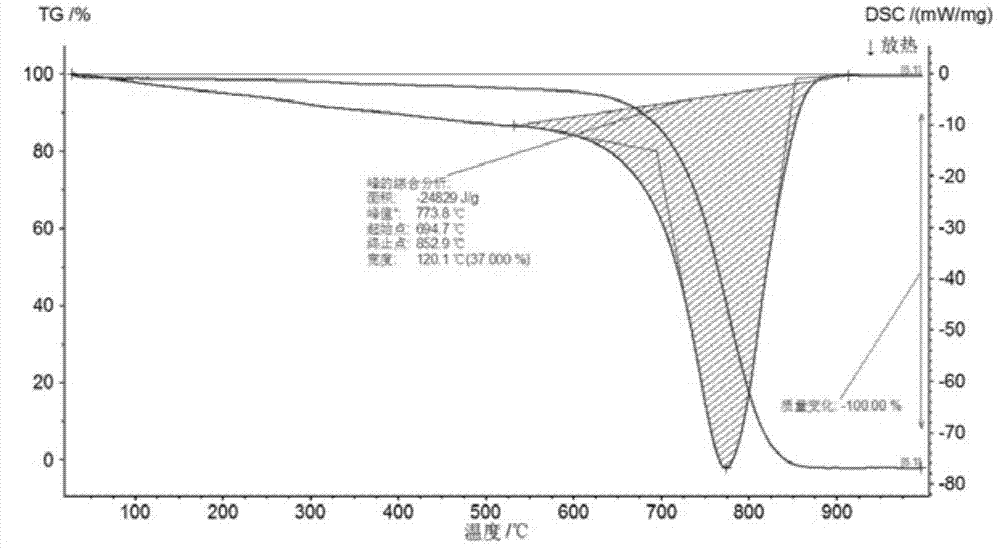

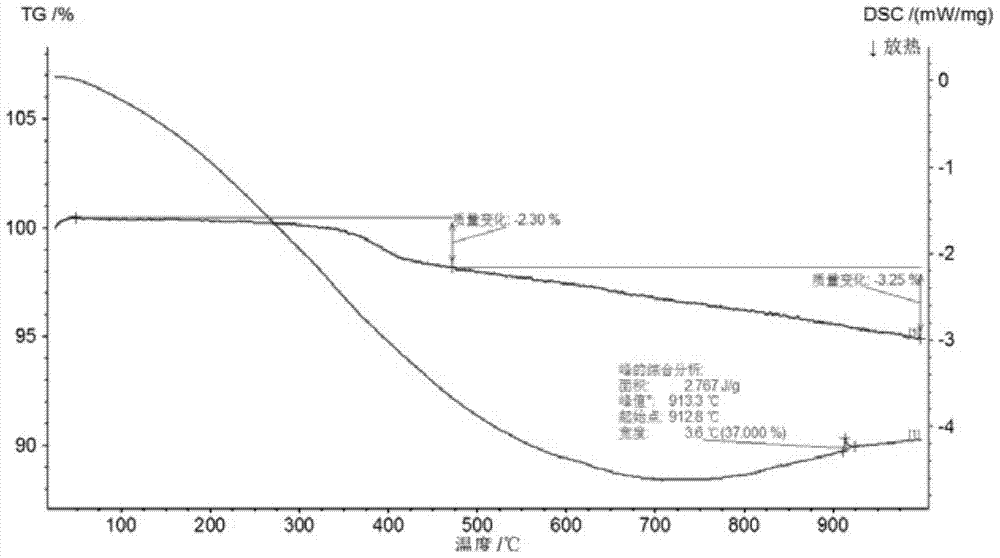

[0034] When the flake graphite in the container sinks to the bottom of the container, drain the 10L dilut...

Embodiment 2

[0044] Soak a 1kg waste lithium battery negative electrode piece in 10L0.3mol / L dilute hydrochloric acid for 8 minutes, and then use a speed-regulating oscillator and a submersible pump to create a tumbling water flow in the container to wash away the negative electrode material. The function makes the separation of graphite and copper sheet more rapid and thorough. The speed of the speed-regulating oscillator is 240r / min, the power of the submersible pump is 60w, the working time is 6min, and then stand still for 10min. Sieve and sieve to obtain copper flakes on the sieve and graphite on the sieve.

[0045] After taking out the copper sheet with dilute hydrochloric acid attached to the surface, immediately soak it in an ultrasonic cleaning machine for 5 minutes, then filter it out and place it in a blast drying oven, and dry it to a constant weight at 60°C to obtain a 312g high Pure copper sheet.

[0046] After the flake graphite in the container sinks to the bottom of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com