Doped silicon quantum dot light emitting diode device and preparation method thereof

A technology of quantum dot light-emitting and light-emitting diodes, which is applied in semiconductor devices, electrical components, circuits, etc., to achieve the effect of enhancing radiation recombination probability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

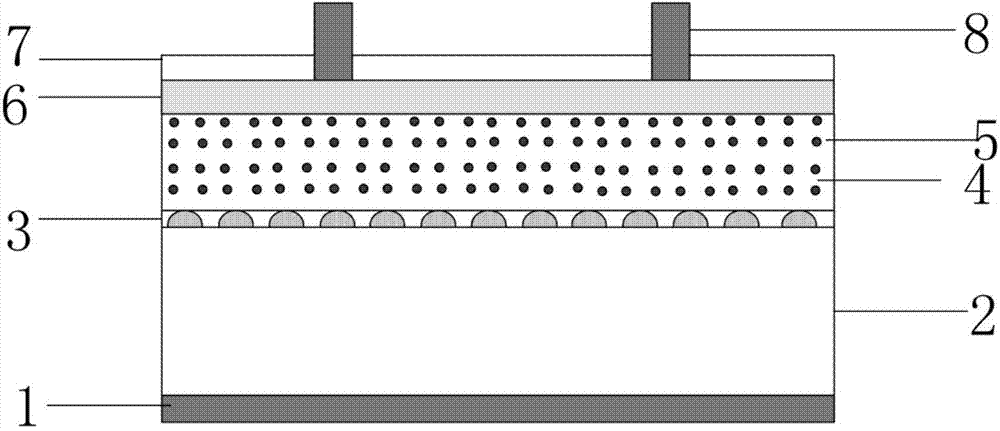

[0038] Specifically, the aforementioned SiN-based x The preparation method of the textured doped silicon quantum dot light-emitting diode device comprises the following steps:

[0039] (1) In clean P with epitaxial layer + Deposit a layer of silver nanometer layer on the P-type silicon substrate 2, and perform rapid thermal annealing treatment to form the silver nanoparticle layer 3. Wherein, the thickness of the silver nanoparticle layer 3 is 30nm to 40nm. The process used can be vacuum evaporation, electron beam evaporation or pulsed laser deposition. The annealing temperature of the rapid thermal annealing treatment is 400-500°C, and the annealing time is 60-120s.

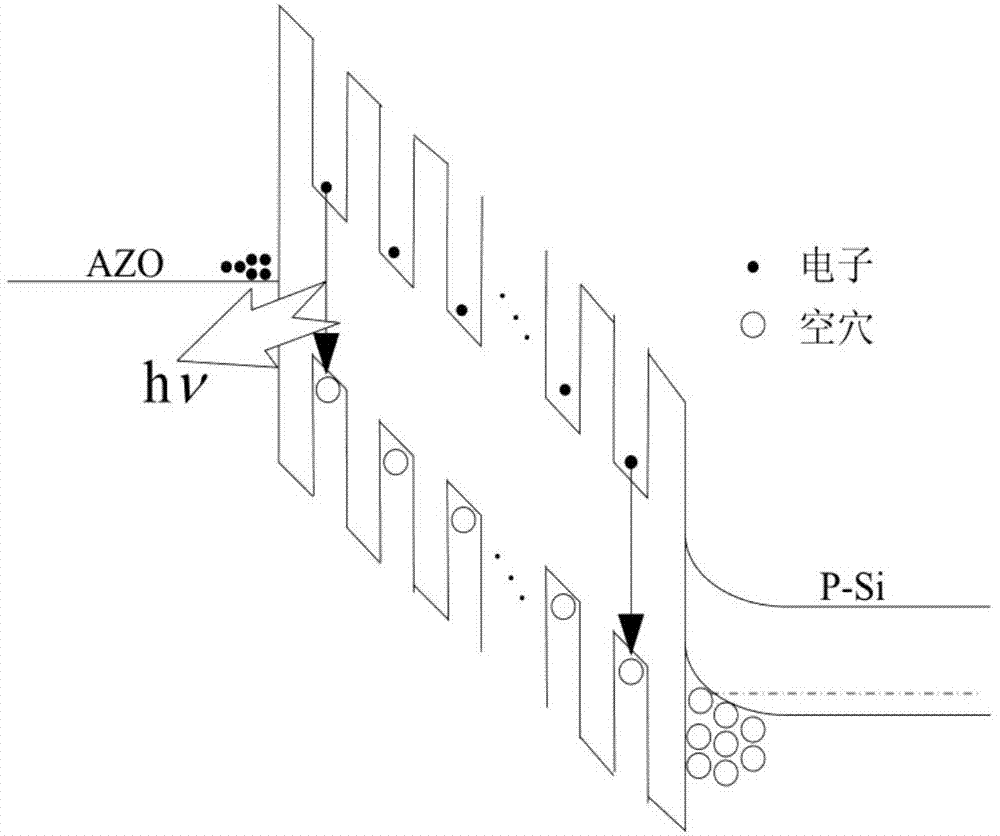

[0040] (2) Alternate deposition of multiple layers of Si on the silver nanoparticle layer 3 3 N 4 layer 4 and doped silicon-rich SiN x Layer 5, made of Si 3 N 4 The distance between layers 4 controls the size of the silicon quantum dots, annealing is performed in an argon environment, and doped silicon q...

example 1

[0047] (1) Use the standard RCA method to clean the P with epitaxial layer + / P-type single crystal silicon substrate 2;

[0048] (2) Form a layer of silver nano-film with a thickness of 30nm on the clean substrate 2 by vacuum evaporation method, and then perform rapid heat treatment to form the silver nano-particle layer 3, wherein the temperature of rapid annealing is 400°C, and the annealing time is 90s;

[0049] (3) Alternating deposition thickness of Si on the silver nanoparticle layer 3 by plasma enhanced chemical vapor deposition (PECVD) technique 3 N 4 Control layer 4 / Silicon-rich SiN doped with phosphorus (P) x Layer 5; deposition 4 into NH 3 (purity is 99.999%) flow rate is 30sccm, by H 2 SiH diluted 10% by volume 4 The flow rate is 60sccm, the deposition time of layer 4 is 15s, and a total of 16 layers are deposited; deposition 5 is fed with NH 3 (purity is 99.999%) flow rate is 10sccm, by H 2 SiH diluted 10% by volume 4 The flow rate is 60sccm, by H 2 PH w...

example 2

[0057] (1) Use the standard RCA method to clean the P with epitaxial layer + / P-type single crystal silicon substrate 2;

[0058] (2) Form a layer of silver nano-film with a thickness of 30nm on the clean substrate 2 by vacuum evaporation method, and then perform rapid heat treatment to form the silver nano-particle layer 3, wherein the temperature of rapid annealing is 400°C, and the annealing time is 90s;

[0059] (3) Alternating deposition thickness of Si on the silver nanoparticle layer 3 by plasma enhanced chemical vapor deposition (PECVD) technique 3 N 4 Control layer 4 / Silicon-rich SiN doped with phosphorus (P) x Layer 5; deposition 4 into NH 3 (purity is 99.999%) flow rate is 30sccm, by H 2 SiH diluted 10% by volume 4 The flow rate is 60sccm, the deposition time of layer 4 is 15s, and a total of 20 layers are deposited; deposition 5 is fed with NH 3 (purity is 99.999%) flow rate is 10sccm, by H 2 SiH diluted 10% by volume 4 The flow rate is 60sccm, by H 2 PH w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com