An ultra-small textured solar cell combined with zinc oxide nanostructure and its preparation method

A zinc oxide nanometer, ultra-small suede technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of poor electrode contact performance and low carrier collection efficiency, and achieve increased lateral transmission capacity and good trapping. The effect of light action, silicon processing technology mature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

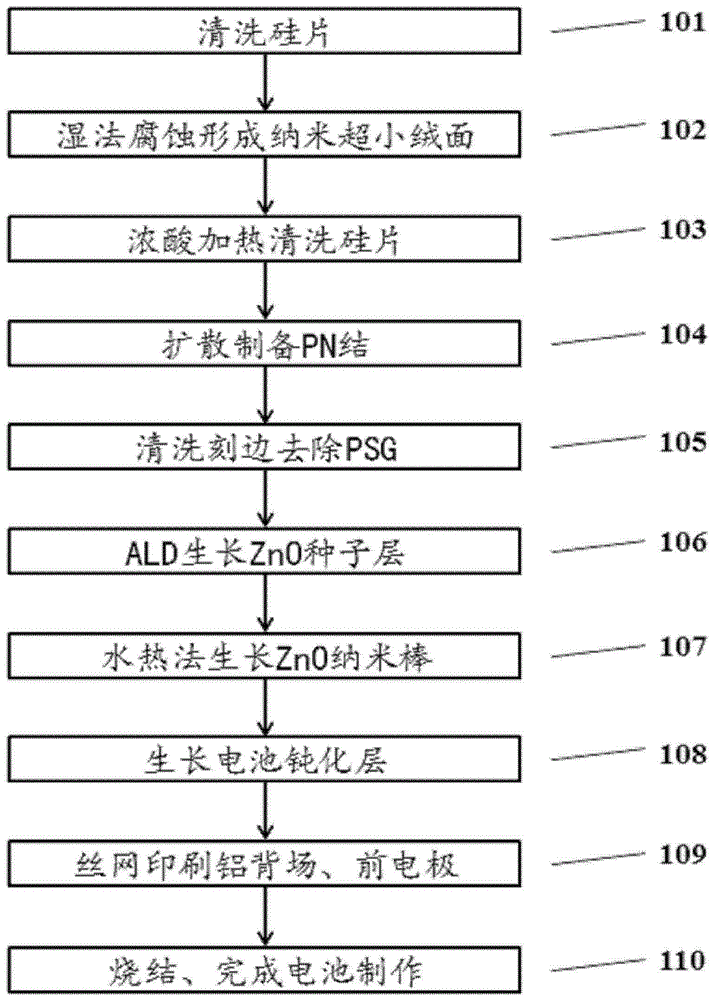

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

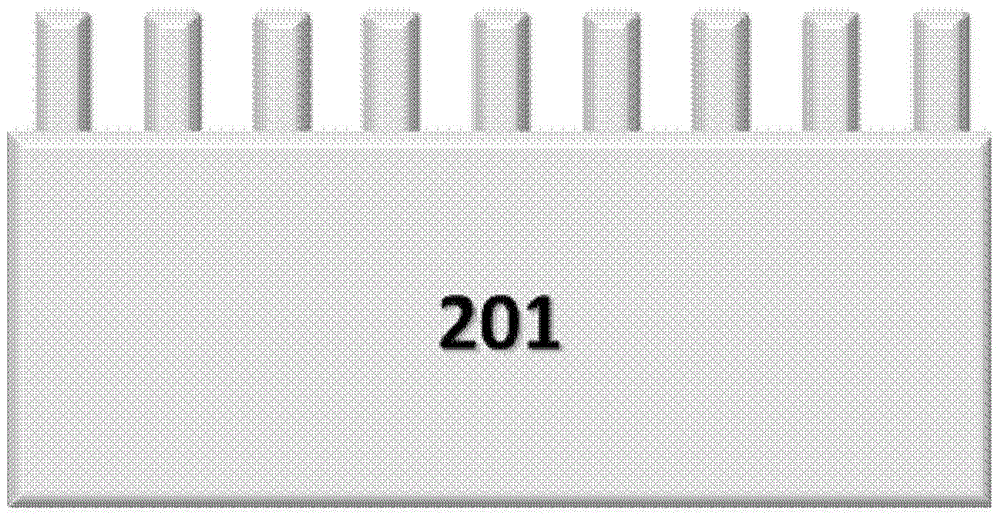

[0041]The embodiment of the present invention proposes an ultra-small textured solar cell combined with zinc oxide nanostructure, the solar cell includes: a silicon wafer with an ultra-small textured surface on the surface; a PN junction is formed on the silicon wafer near the nano-sized ultra-small textured structure ; ZnO nanostructures grown on ultra-textured surfaces and in interstices; passivation layer on the ultra-textured side of the silicon wafer; silver paste on the ultra-textured side of the silicon wafer to form solar The front electrode of the cell; and the aluminum paste on the side of the silicon wafer without the microtexture to form the back electrode of the solar cell.

[0042] Wherein, the ultra-small t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com