Ball worm gear pair

A worm and ball technology, applied in portable lifting devices, gear transmissions, components with teeth, etc., can solve the problems of unbalanced, high energy consumption, high heat generation, etc., achieve simple lubrication and maintenance, prolong service life, and lubricate The effect of less oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

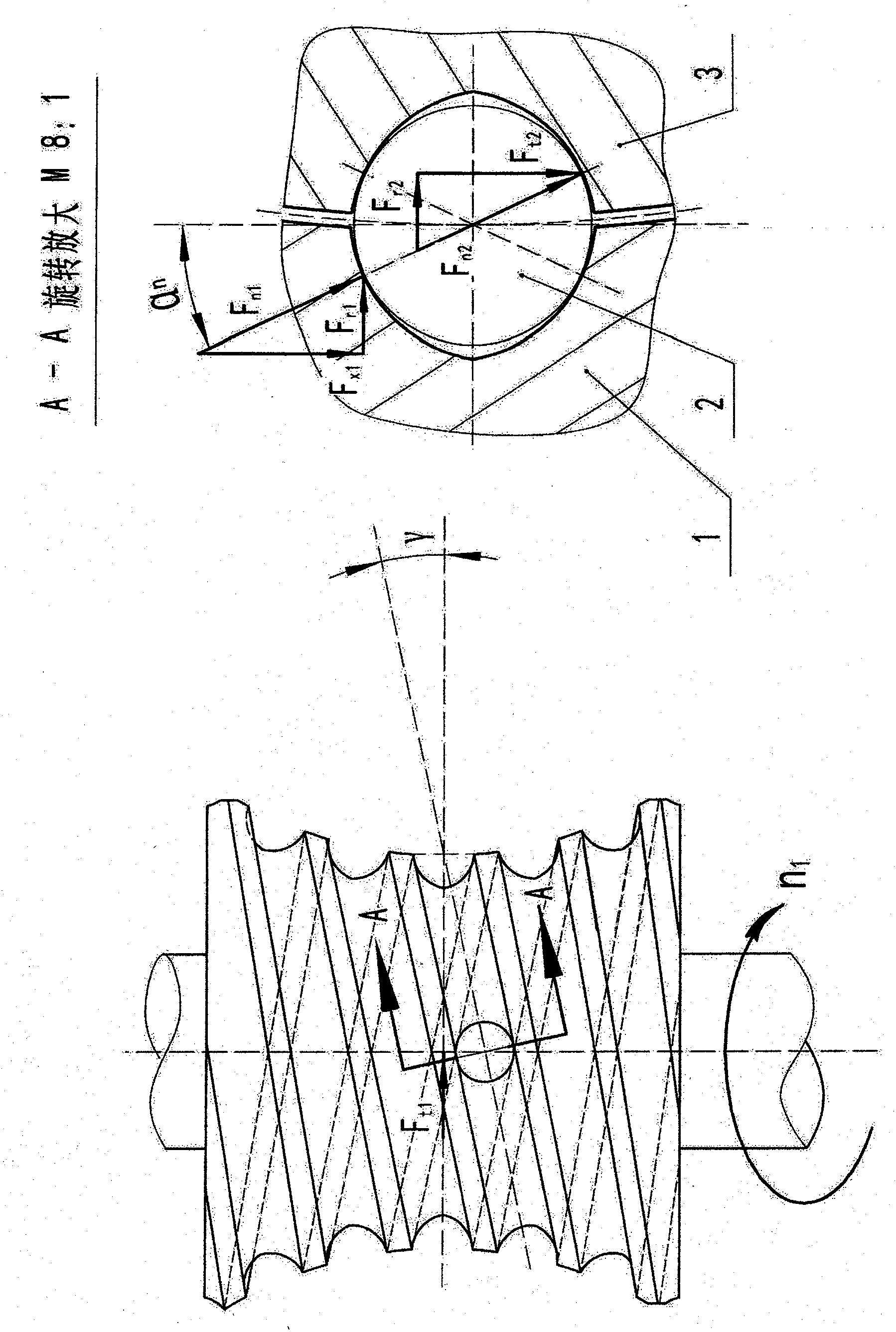

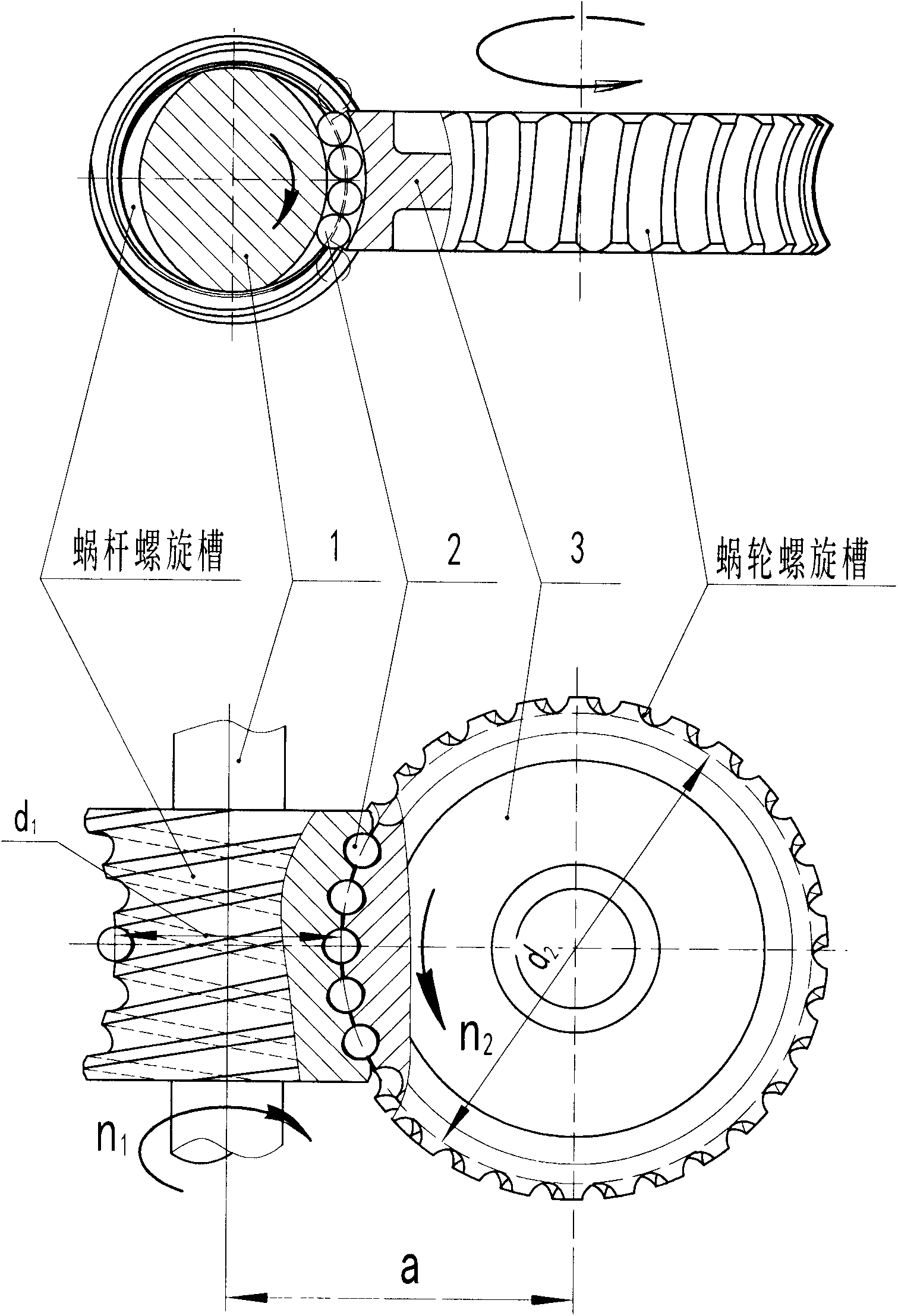

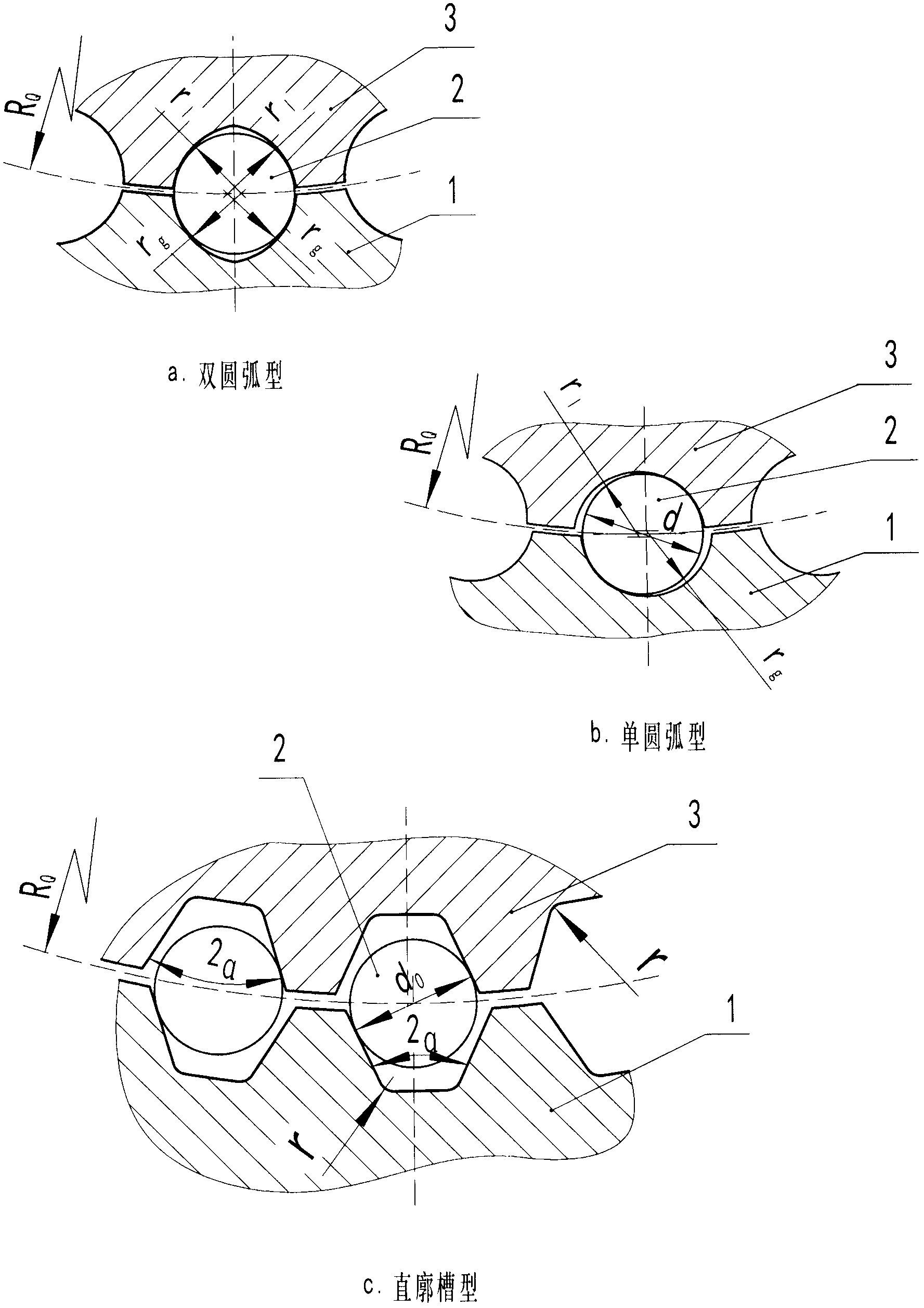

[0025]The ball worm pair proposed by the present invention has two types of envelopes (single envelope and double envelope), three types of spiral grooves and four types of steel ball circulation paths, which can be combined into dozens of different types of structures. The combined structure should be determined according to various factors such as the type of load to be transmitted, accuracy requirements, environmental conditions, and production conditions. Several typical examples are presented here to illustrate the specific structural combination of two types of envelopes, three types of spiral grooves, and four types of steel ball circulation methods proposed by the present invention, their advantages and disadvantages, and applicable occasions.

[0026] Figure 4 Shown is a double-enveloping worm pair, which adopts the implementation mode of double arc spiral grooves. The steel balls circulate through the guide tubes 5, 6 and guide holes installed at both ends of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com