Rotary Polishing Apparatus with Blade Constraining Members

A technology of constraining components and polishing devices, which is applied in the field of abrasive flow polishing processing devices for titanium alloy artificial joints, to achieve high polishing precision, good polishing effect, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

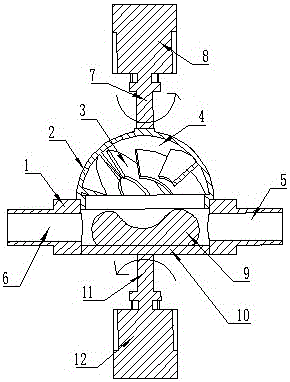

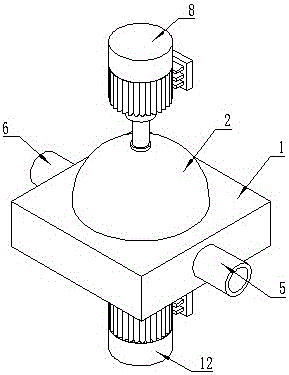

[0016] combine Figure 1~4 , a rotary polishing device with blade constraining components, including a box body 1 and a cover body 2; a rotating device is provided at the center of the box body 1, and the rotating device includes a turntable 10, a connecting shaft 11, and a motor 12, and the turntable 10 is installed in the box body 1 , the motor 12 is installed outside the box body 1, the motor 12 is connected to the turntable 10 through the connecting shaft 11, and the workpiece 9 is installed on the turntable 10.

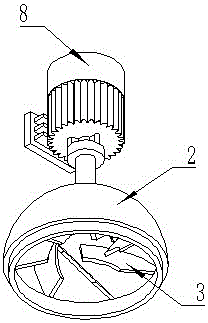

[0017] The cover body 2 is set on the top of the box body 1, the top of the cover body 2 is connected to the motor 8 through the rotating shaft 7, the cover body 2 can rotate around the rotating shaft 7, the inner surface of the cover body 2 is a semi-spherical surface, and the inner surface of the cover body 2 is evenly distributed with blades 3 The blade 3 is obliquely welded on the inner surface of the cover body 2, and a sealed polishing chamber 4 is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com