Method for finishing and grinding large accurate threaded hole and grinding tool

A technology for grinding tools and precision threads, which is applied to the grinding method of large precision threaded holes and the field of grinding tools. It can solve the problems of large risk of large threaded holes, high processing risk, and difficulty in ensuring the uniformity of polishing, etc., to achieve excellent screw teeth. Surface quality, simple and fast operation process, and less additional removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

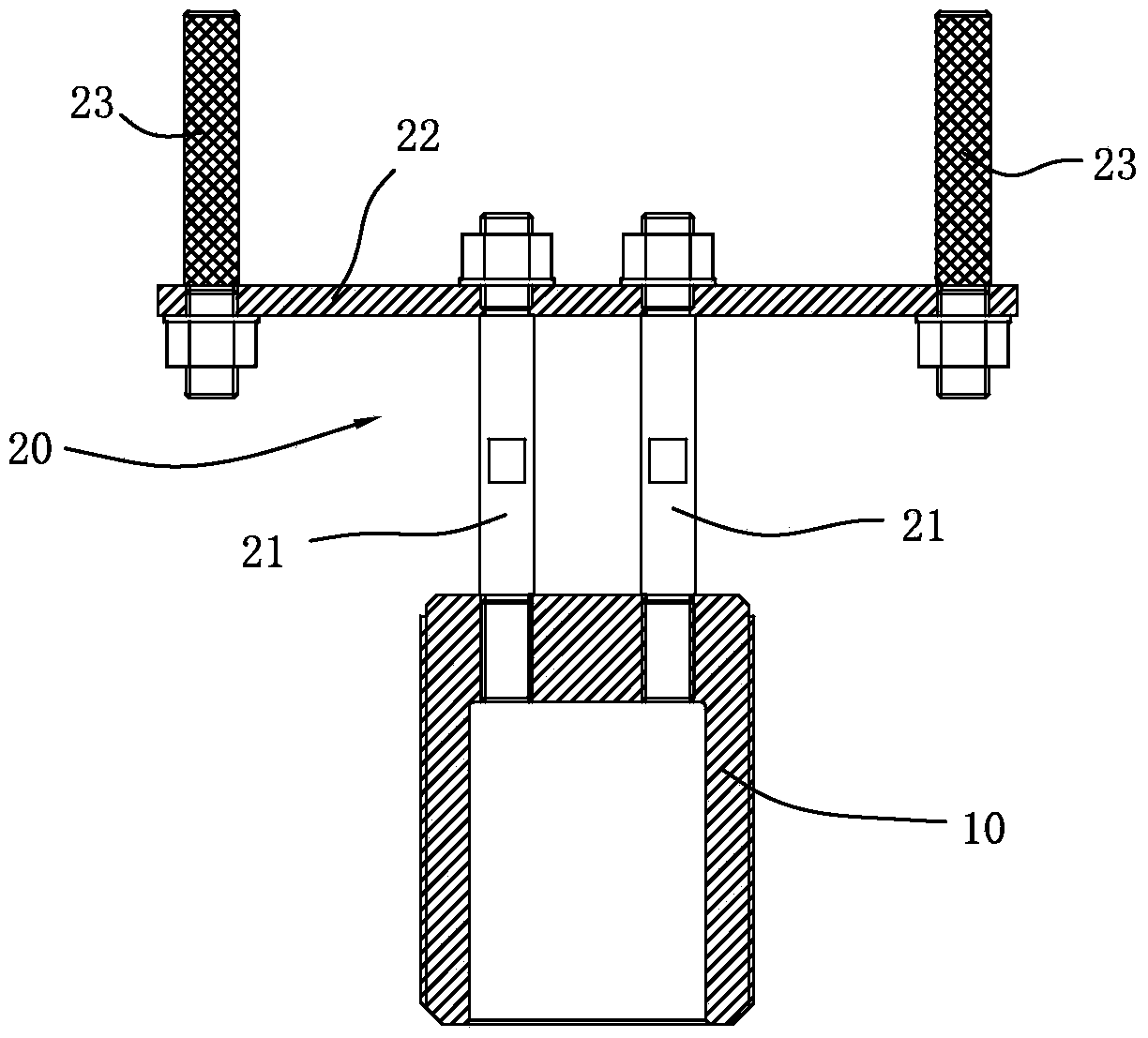

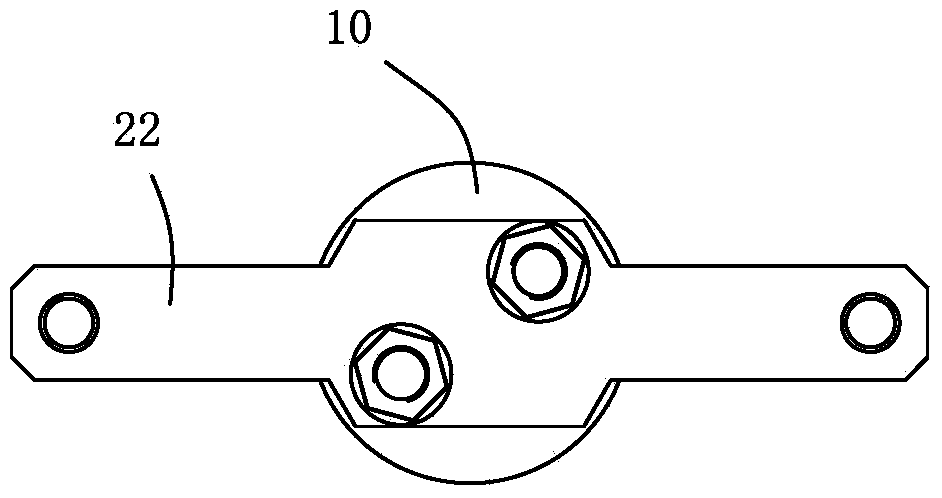

[0026] The method for finishing and grinding large precision threaded holes of the present invention is mainly aimed at large threaded holes such as M155 threaded holes, especially when the surface quality of the threads in the threaded holes is required to be very high.

[0027] A method for finishing and grinding large precision threaded holes of the present invention comprises the following steps:

[0028] (1) Check and clean the threaded holes, determine the amount of grinding and select the appropriate size of grinding paste;

[0029] (2) Apply grinding paste to the threaded surface and / or threaded hole of the grinding rod;

[0030] (3) Slowly screw the grinding rod body into the threaded hole, and repeatedly rotate the grinding rod body back and forth for grinding;

[0031] (4) According to the amount of grinding in step (1), after the grinding time or the number of rotations of the grinding rod reaches a predetermined value, stop grinding and exit the grinding rod;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com