Rolling assembly mechanism and method

An assembly mechanism and rolling wheel technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve assembly technical requirements (extrusion bonding force cannot meet drawing requirements, component straightness, flatness, etc. It is not easy to guarantee the position tolerance, there is no suitable fixture and unique process plan, etc., to achieve the effect of excellent rolling effect, simple structure and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

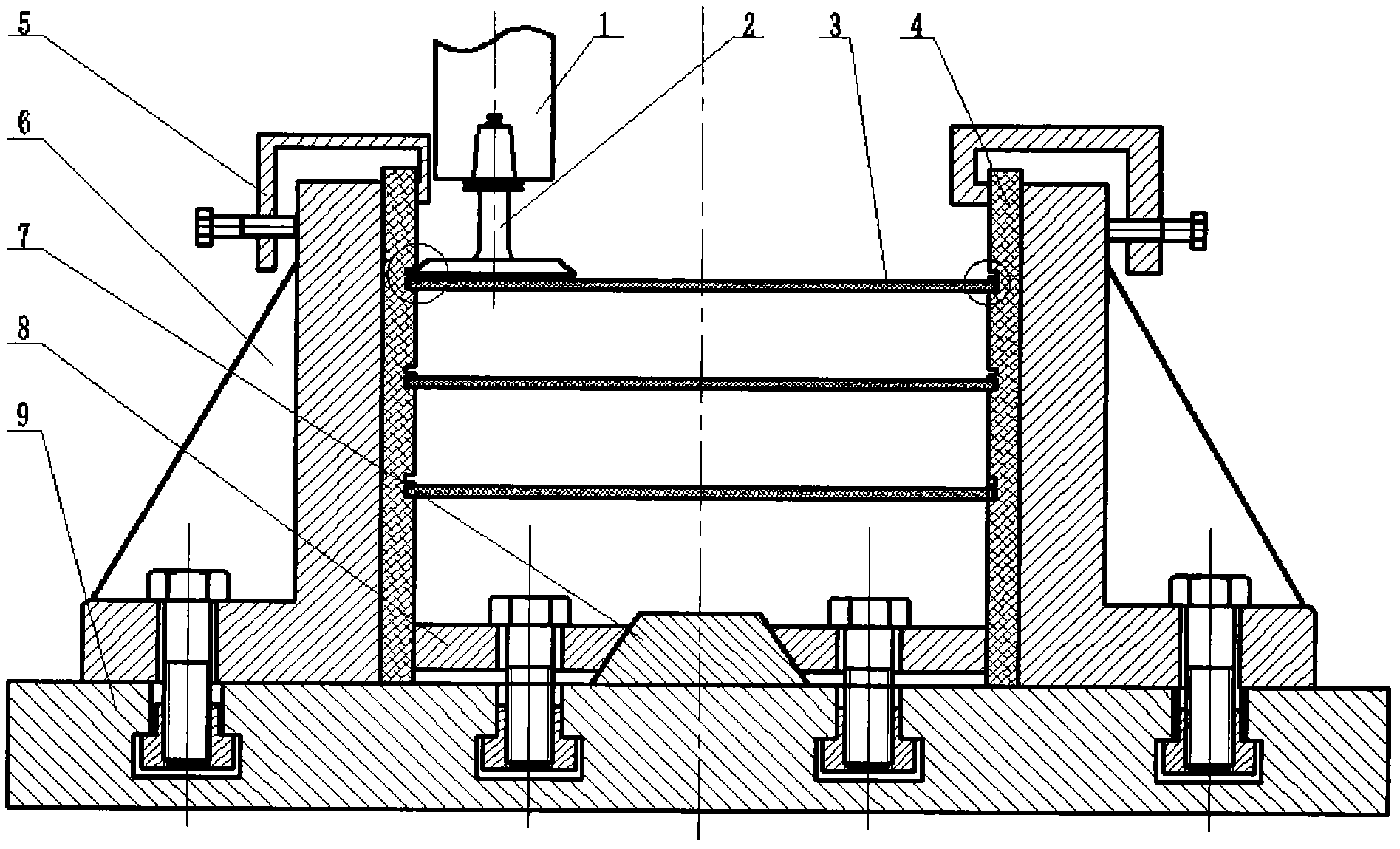

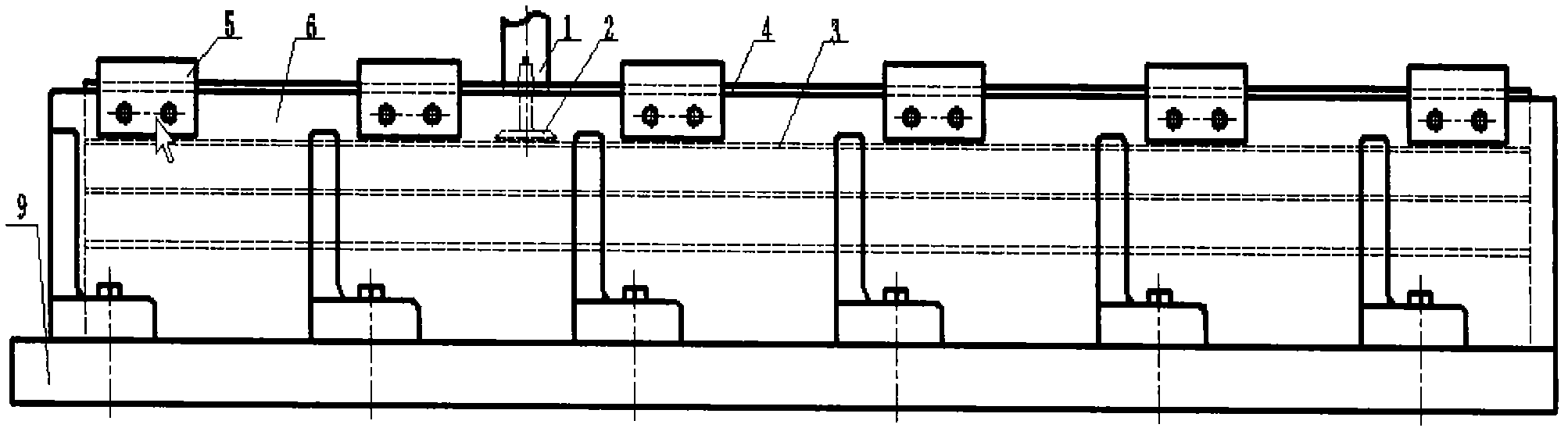

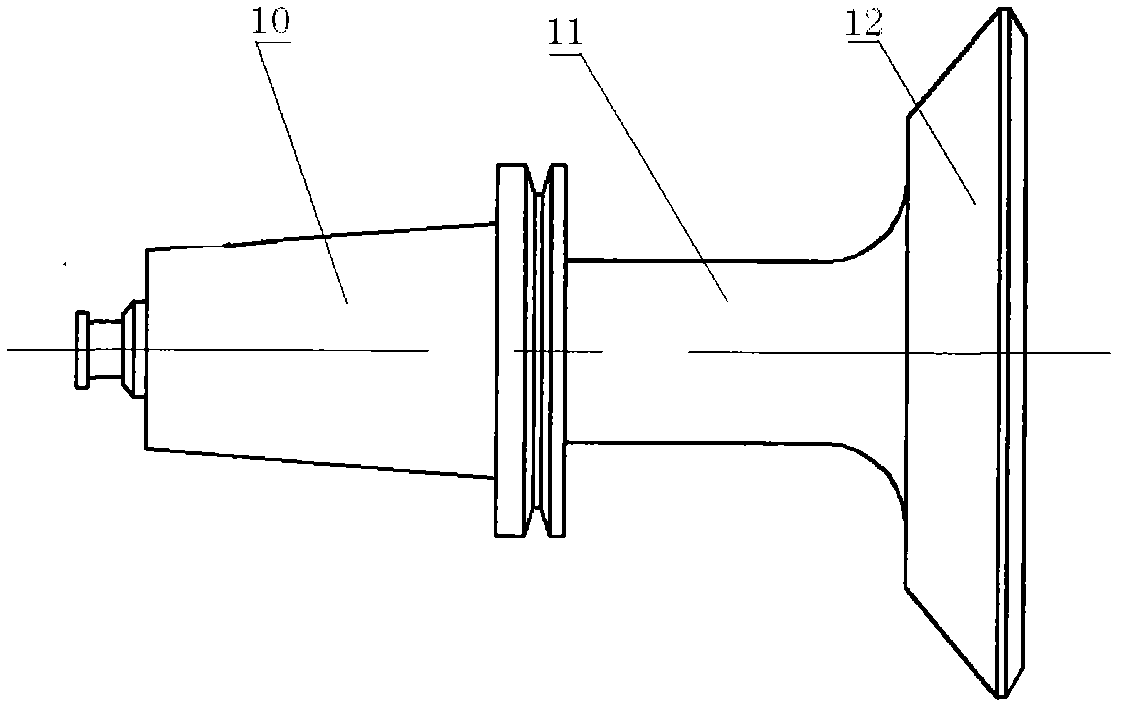

[0034] A rolling assembly mechanism, comprising: a CNC machine tool workbench 1, a symmetrically arranged clamping support body 6 is fixedly installed on the CNC machine tool workbench, the clamping support body 6 is provided with reinforcing ribs, and the inner wall of the clamping support body 6 There are workpieces 4 on the top respectively, the clamping support body 6 and the upper part of the workpiece 4 are fastened by the clamp 5, the opposite surface of the workpiece 4 is symmetrically opened with a rolling groove, and the second workpiece 3 is installed in the rolling groove, and the inner bottom of the workpiece 4 is opposite A first clamping wedge 8 and a second clamping wedge 7 are provided respectively, and the second clamping wedge 7 is placed in the middle of the first clamping wedge 8 .

[0035] The rolling assembly steps are as follows:

[0036] 1) A symmetrically arranged clamping support body 6 is fixedly installed on the workbench 1 of the CNC machine tool,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com