Sonochemistry preparation method allowing surface of copper powder to be coated with nickel and phosphorus alloy layer

A technology of surface coating and sonochemistry, applied in the direction of coating, etc., can solve the problems of complex process, low nickel deposition rate, harsh experimental conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

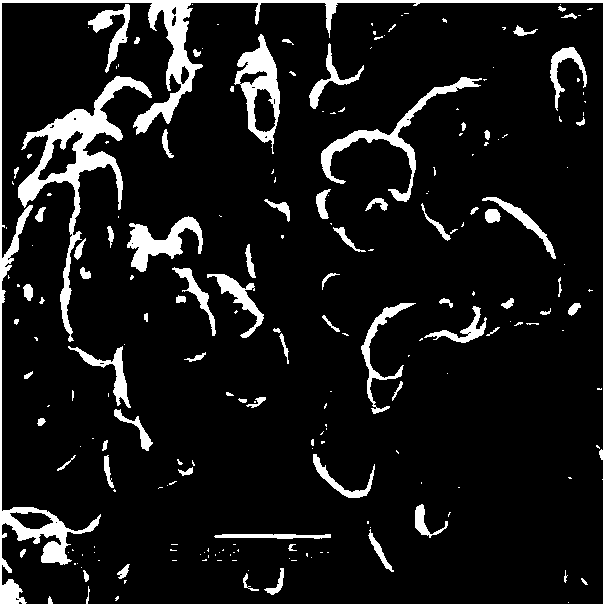

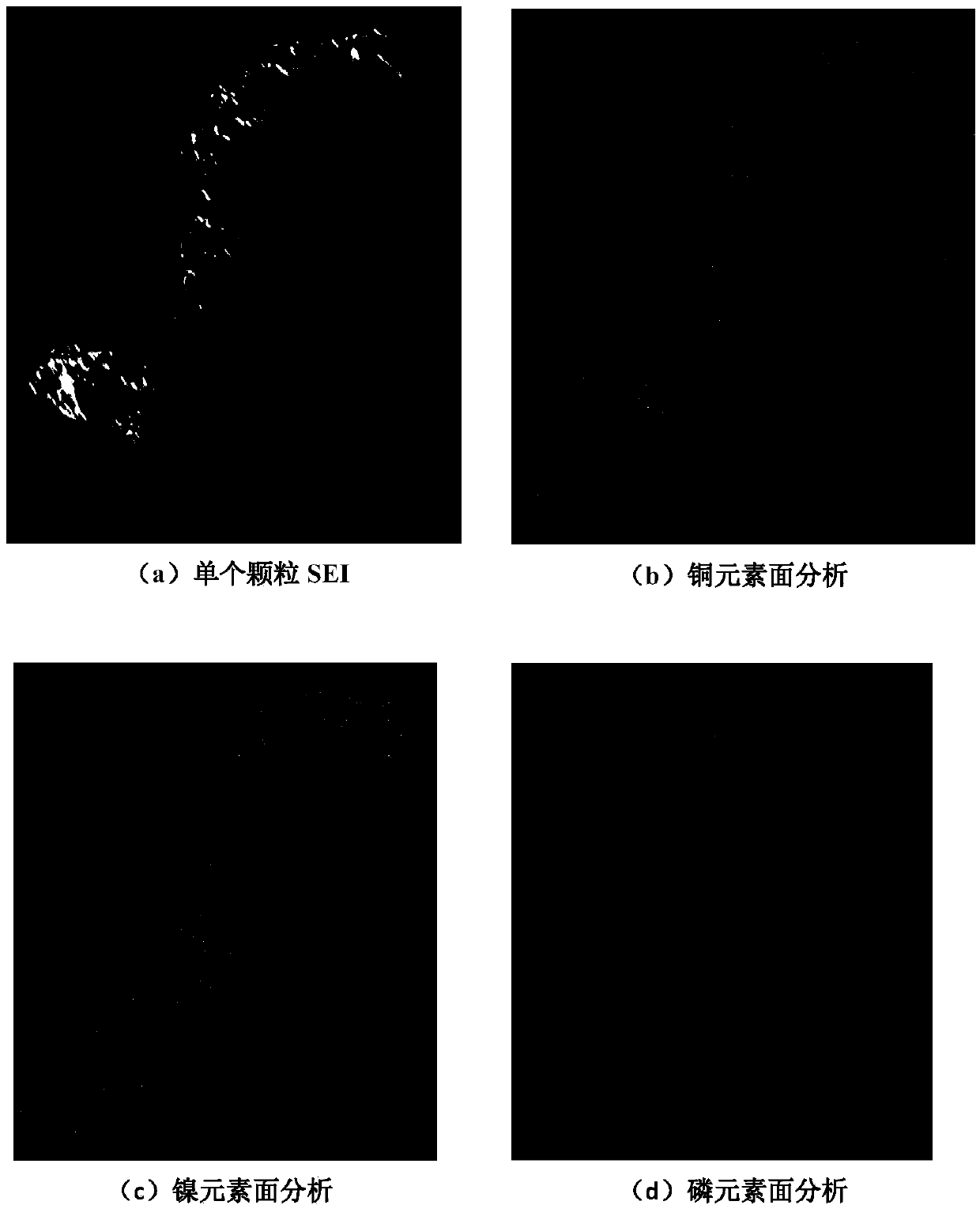

Image

Examples

example 1

[0022] 1) The electronic balance accurately weighs the required chemical reagents: nickel sulfate 60g, sodium hypophosphite 80g, sodium acetate 60g, lactic acid 10g, propionic acid 6g, additive hydrochloric acid (1.18g / cm3), surfactant 0.2g, lead acetate 0.2 mg, the above reagents are all analytically pure; the temperature is 85°C, and the holding time is 5min.

[0023] 2) To prepare a 2L plating solution, first measure half the volume of the required plating solution, dissolve nickel sulfate, sodium acetate, lactic acid and propionic acid in different beakers, and stir the evenly dissolved complexing agent solution Slowly add nickel salt solution, stir evenly, add sodium hypophosphite, stir for 10 minutes, finally add surfactant and lead acetate, constant volume to obtain plating solution.

[0024] 3) Quantitatively weigh 50g of copper powder, after acidification and activation pretreatment, add to the plating solution, stir until the solution is in a suspended state, and adj...

example 2

[0029] 1) The electronic balance accurately weighs the required chemical reagents: nickel sulfate 120g, sodium hypophosphite 160g, sodium acetate 120g, lactic acid 20g, propionic acid 12g, additive hydrochloric acid (1.18g / cm3), surfactant 0.8g, lead acetate 0.4 mg, the above reagents are all analytically pure; the temperature is 85°C, and the holding time is 10min.

[0030] 2) To prepare 4L of plating solution, first measure half the volume of the required plating solution, dissolve nickel sulfate, sodium acetate, lactic acid and propionic acid in different beakers, and stir the evenly dissolved complexing agent solution Slowly add nickel salt solution, stir evenly, then add sodium hypophosphite, stir for 20 minutes, finally add surfactant and lead acetate, constant volume to obtain plating solution.

[0031] 3) Quantitatively weigh 120g of copper powder, after acidification and activation pretreatment, add it to the plating solution, stir until the solution is in a suspended s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com