Manufacturing method of flexible printed circuit board

A flexible printed circuit, flexible printing technology, applied in the direction of printed circuit manufacturing, printed circuit, multilayer circuit manufacturing, etc., can solve the problems of increasing workload, affecting production efficiency, and inconvenient multilayer boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

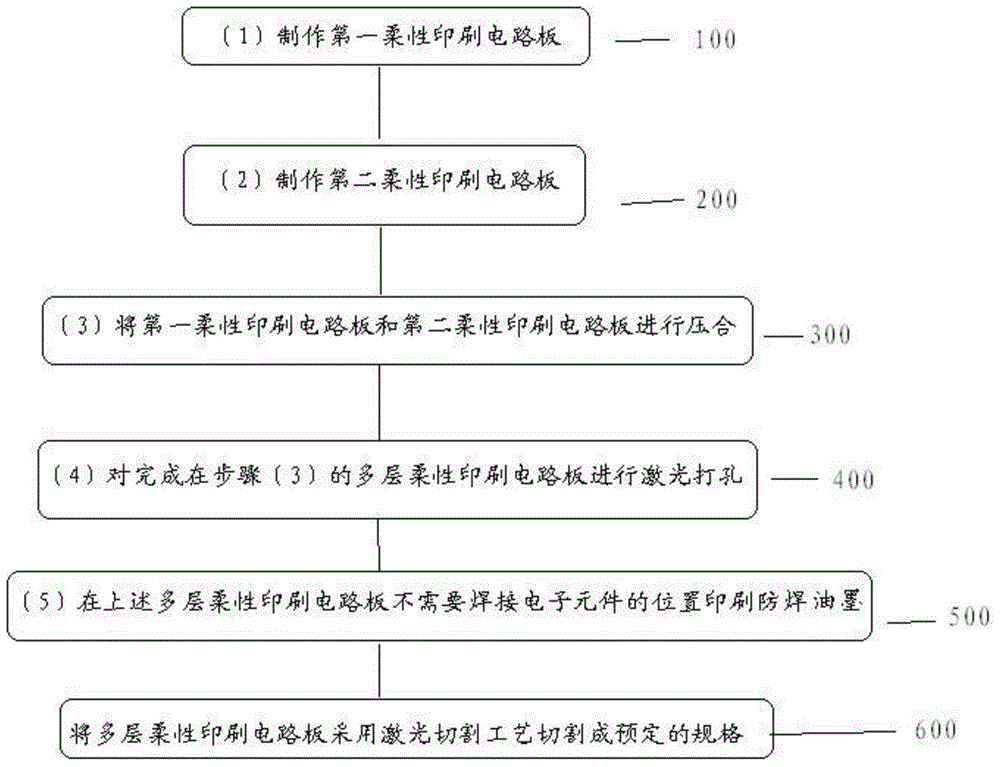

[0032] see figure 1 , the manufacturing method of the flexible printed circuit board that the present invention proposes comprises the following steps successively:

[0033] (1) Making the first flexible printed circuit board ( figure 1 100 in);

[0034] (2) Make the second flexible printed circuit board ( figure 1 200 in);

[0035] (3) Pressing the first flexible printed circuit board and the second flexible printed circuit board ( figure 1 300 in);

[0036] (4) Laser drilling the multilayer flexible printed circuit board completed in step (3) ( figure 1 400 in);

[0037] (5) Print solder resist ink on the above-mentioned multi-layer flexible printed circuit board where the electronic components do not need to be soldered ( figure 1 500 in);

[0038] (6) Cut the multi-layer flexible printed circuit board into predetermined specifications by laser cutting process ( figure 1 600 in).

[0039] Among them, step (1) specifically includes the following steps:

[0040] (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com