Method for isolating carbazole from anthracene oil

A technology for carbazole and anthracene oil is applied in the field of separation of carbazole to achieve the effects of simplified separation process, simplified separation process and reduced toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

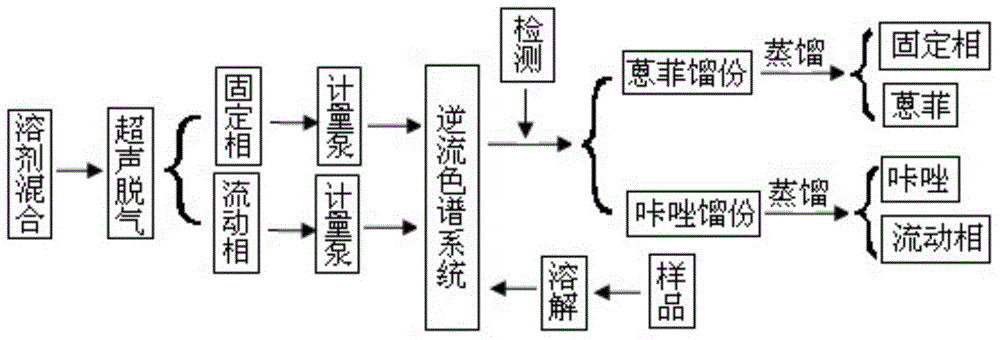

Method used

Image

Examples

Embodiment 1

[0035] The method for separating carbazole from anthracene oil in this embodiment includes the following steps:

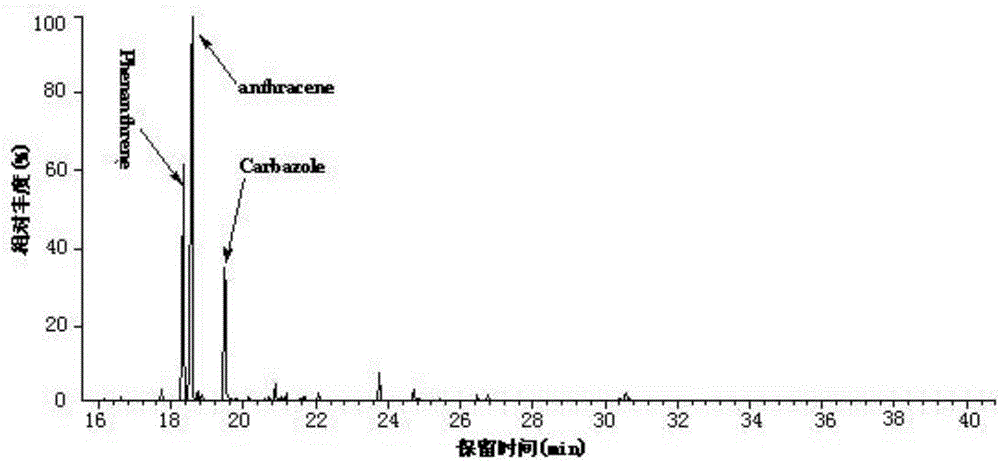

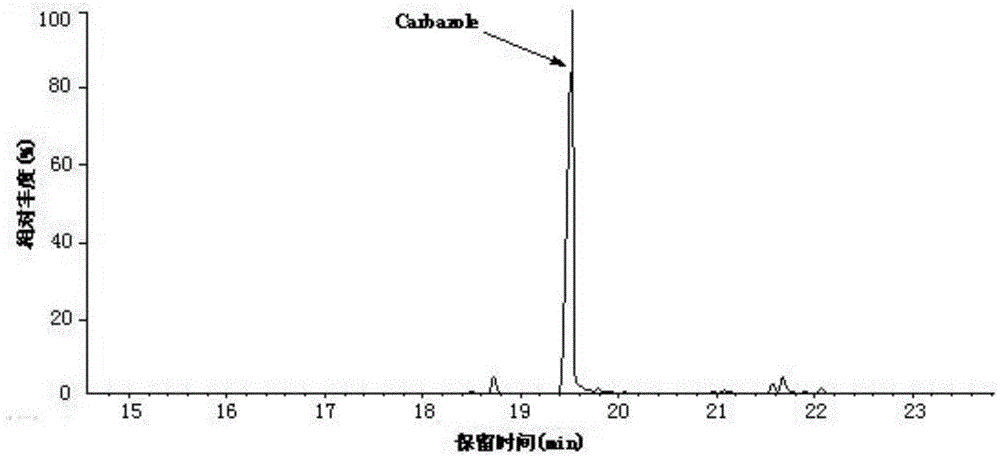

[0036] (1) Take 0.2655g of crude anthracene. The quality analysis results of the main components in crude anthracene are shown in Table 1 below and figure 2 ;

[0037] (2) Prepare solvent system

[0038] The volume ratio is n-heptane: benzene: acetone: acetonitrile = 4.5:1:1:4.5. Take each solvent, mix it with ultrasonic and degas for 20min, let it stand overnight to make the two-phase solvent reach a full equilibrium, and separate the solvent system Store the upper and lower phases in a closed container;

[0039] (3) Check each line interface of the complete set of TBE-300B high-speed countercurrent chromatograph to ensure that the connection is correct. Use the upper phase of the solvent system as the stationary phase and use a constant flow pump to input the spiral tube column of the countercurrent chromatograph until the column is full; The counter-current chromatogr...

Embodiment 2

[0044] The method for separating carbazole from anthracene oil in this embodiment includes the following steps:

[0045] (1) Take 0.5331g of decrystallized anthracene oil, and the quality analysis results of the main components are shown in Table 2 below and Figure 4 ;

[0046] (2) According to the volume ratio as cyclohexane:benzene:acetone:ethanol=3:2:2:3, take each solvent, mix it with ultrasonic and degas for 20min, let it stand overnight to make the two-phase solvent reach full equilibrium, and separate Store the upper and lower phases of the solvent system in a closed container;

[0047] (3) The countercurrent chromatography device is the same as in Example 1. The decrystallized anthracene oil is dissolved in the lower phase, the preparation volume is 30mL, the circulating water bath temperature is controlled to 45℃, the mobile phase flow rate is 3mL / min, and the stationary phase flow rate is 20mL / min. In forward mode, the speed of the main engine is 500 rpm, and other operat...

Embodiment 3

[0053] The method for separating carbazole from anthracene oil in this embodiment includes the following steps:

[0054] (1) Take 0.5508g of anthracene oil, and the quality analysis results of its main components are detailed in Table 3 and Image 6 ;

[0055] (2) Prepare solvent system

[0056] The volume ratio is n-hexane: benzene: acetone: methanol=7:2:2:7. Take each solvent, mix it with ultrasonic and degas for 20 minutes, and let it stand overnight to make the two-phase solvent reach a full equilibrium. Store the upper and lower phases in a closed container;

[0057] (3) The countercurrent chromatography device is the same as in Example 1. The anthracene oil is dissolved in the lower phase, the preparation volume is 30mL, the circulating water bath temperature is controlled to 40℃, the mobile phase flow rate is 3mL / min, and the stationary phase flow rate is 20mL / min. Mode, the host speed is 700rpm, other operations are the same as in Example 1;

[0058] (4) Observe the detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com