Pyroelectric material and preparation method thereof

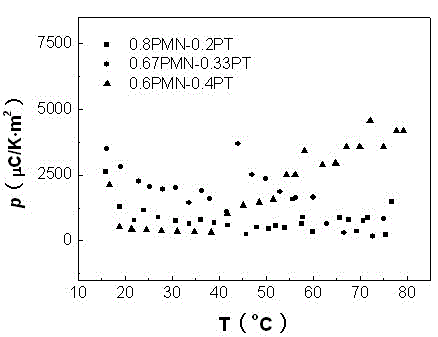

A pyroelectric and current response technology, applied in the field of pyroelectric materials, can solve the problems of difficulty in improving the lateral thermal time constant of pyroelectric detectors, large dielectric loss, and low permittivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

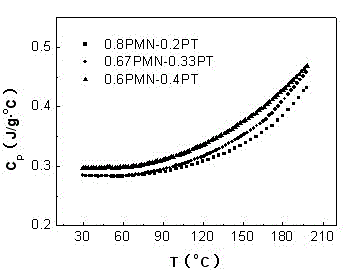

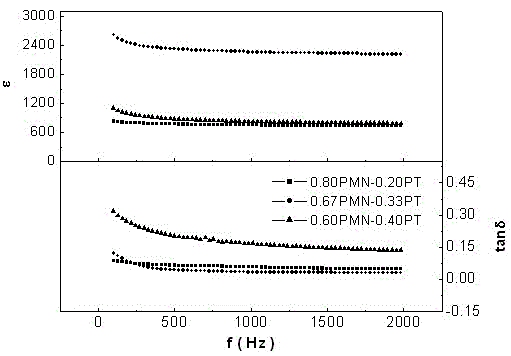

[0016] (1-x)Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -xPbTiO 3 (PMNT, x=0.2-0.8) ceramics. Weigh MgO, Nb according to stoichiometric ratio 2 o 5 、TiO 2 , wet grinding and mixing evenly, and calcined at 1000°C for 3h to prepare the B-site precursor. The B-site precursor was crushed and ground and dispersed in an oxalic acid aqueous solution to prepare a suspension. The concentration of the oxalic acid aqueous solution was 2mol / L; weighed stoichiometric Pb(CH 3 COO) 2 ·3H 2 O is prepared into an aqueous solution of 1.5mol / L, and in the above two solutions, Pb(CH 3 COO) 2 :H 2 C 2 o 4 =1:1.5; Pb(CH 3 COO) 2 The solution is slowly dropped into the above suspension to form PbC 2 o 4 Evenly coat the precipitation of the B-site precursor; precipitate washing, filtering, and calcining at 750°C for 2 hours to obtain PMNT powder with perovskite structure; after the calcined product is crushed and ground, add 3wt of PMNT powder with perovskite structure % polyvinyl alcohol (PVA) granulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com