Method for preparation of chemical raw materials by using of potassium-containing shale

A chemical raw material, potassium shale technology, applied in chemical instruments and methods, inorganic chemistry, iron compounds, etc., can solve problems such as impurities, achieve the effect of increasing economic benefits, improving decomposition rate, and solving demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

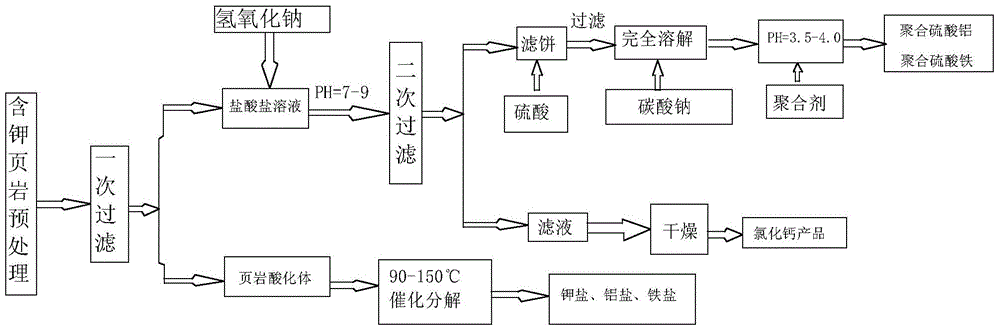

Image

Examples

Embodiment 1

[0026] Take potassium-containing shale (sandstone) powder crushed to 100 mesh and add hydrochloric acid with a mass percentage concentration of 6% to mix evenly according to the mass ratio of 1:0.2, then transfer it to the reactor for pretreatment, keep stirring, and wait for the pretreatment After 2.5 hours of treatment, filter once to obtain hydrochloride solution and shale acidification body. Then, the shale acidification body is catalytically decomposed at a temperature of 100° C. to obtain aluminum salts, iron salts, potassium salts, and calcium salts. And the filtrate is added calcium hydroxide emulsion under constant stirring, the amount of calcium hydroxide in the emulsion accounts for 10% of the filtrate weight, adjust the pH value to 7.5, carry out secondary filtration, and dry the filtrate of secondary filtration Calcium chloride dihydrate. Then the filter cake and sulfuric acid are mixed according to the volume ratio of 1:1, and stirred to dissolve the filter cake...

Embodiment 2

[0028] Take potassium-containing shale (sandstone) powder crushed to 110 mesh, add 3600ml of hydrochloric acid with a concentration of 18% by mass, mix evenly, transfer it to the reaction kettle for pretreatment, stir continuously, and do it once after 2 hours of pretreatment Filtration to obtain hydrochloride solution and shale acidification body. Then, the shale acidification body is decomposed catalytically at a temperature of 90°C to obtain aluminum salts, iron salts, potassium salts, and calcium salts; and the filtrate is added to calcium hydroxide emulsion under continuous stirring, and the hydroxide in the emulsion is The amount of calcium accounts for 5% of the weight of the filtrate, adjust the pH value to 7, perform secondary filtration, and dry the filtrate of the secondary filtration to obtain calcium chloride dihydrate. Then the filter cake and sulfuric acid are mixed according to the volume ratio of 1:1, and stirred to dissolve the filter cake in sulfuric acid. A...

Embodiment 3

[0030] Take potassium-containing shale (sandstone) powder crushed to 120 mesh, add hydrochloric acid with a mass percentage concentration of 36%, mix evenly according to the mass ratio of 1:4, and then transfer it to the reactor for pretreatment, stirring continuously, and wait for the pretreatment After 3.5 hours of treatment, filter once to obtain hydrochloride solution and shale acidification body. Then, the shale acidification body is catalytically decomposed at a temperature of 120°C to obtain aluminum salts, iron salts, potassium salts, and calcium salts; and the filtrate is added with calcium hydroxide solids under constant stirring, and the weight of calcium hydroxide solids accounts for 1% of the filtrate. 10% by weight, adjust the pH value to 8, perform secondary filtration, and dry the filtrate of the secondary filtration to obtain calcium chloride dihydrate. Then mix the filter cake and sulfuric acid with a mass percentage of 30% according to the volume ratio of 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com