Radiation-resistant halogen-free flame-retardant cable material and preparation method thereof

A flame-retardant cable material and radiation-resistant technology, applied in rubber insulators, organic insulators, etc., can solve the problems of poor radiation resistance and poor durability, achieve excellent flame retardancy, good radiation resistance, and meet long-term radiation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

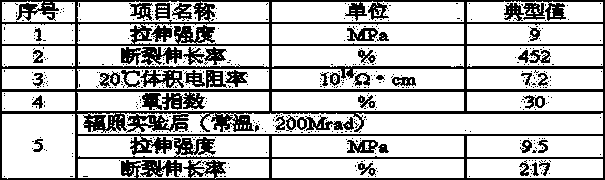

Image

Examples

Embodiment 1

[0034] A radiation-resistant halogen-free flame-retardant cable material according to the present invention is mainly made of the following components and materials by weight:

[0035] EPDM rubber: 100 parts

[0036] Magnesium hydroxide: 60 parts

[0037] Aluminum hydroxide: 40 parts

[0038] Nano hydrotalcite: 10 parts

[0039] Red phosphorus: 8 parts

[0040] Rare earth stearate: 2 parts

[0043] Phenyl silicone rubber: 8 parts

[0044] Phenyl silicone oil: 8 parts

[0045] Polyimide: 5 parts

[0046] Stearic acid: 0.5 parts

[0047] Paraffin: 1.5 parts

[0048] 2-Mercaptobenzimidazole: 0.5 parts

[0049] 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane: 5 parts

[0050] 2,2,4-Trimethyl-1,2-dihydroquinoline: 0.3 parts.

[0051]The preparation method of the cable material of the present invention is: masticating EPDM rubber in an internal mixer for 1-2 minutes, and then adding 1,1-di-tert-butyl perox...

Embodiment 2

[0053] A radiation-resistant halogen-free flame-retardant cable material according to the present invention is mainly made of the following components and materials by weight:

[0054] EPDM rubber: 100 parts

[0055] Magnesium hydroxide: 50 parts

[0056] Aluminum hydroxide: 70 parts

[0057] Nano hydrotalcite: 15 parts

[0058] Red phosphorus: 8 parts

[0059] Rare earth stearate: 3 parts

[0062] Phenyl silicone rubber: 10 parts

[0063] Phenyl silicone oil: 8 parts

[0064] Paraffin: 1.5 parts

[0065] Stearic acid: 0.5 parts

[0066] 2-Mercaptobenzimidazole: 0.5 parts

[0067] 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane: 5 parts

[0068] 2,2,4-Trimethyl-1,2-dihydroquinoline: 0.3 parts.

[0069] The preparation method of the cable material is the same as in Example 1.

Embodiment 3

[0071] A radiation-resistant halogen-free flame-retardant cable material according to the present invention is mainly made of the following components and materials by weight:

[0072] EPDM rubber: 100 parts

[0073] Magnesium hydroxide: 60 parts

[0074] Aluminum hydroxide: 60 parts

[0075] Nano hydrotalcite: 5 parts

[0076] Red phosphorus: 10 parts

[0077] Rare earth stearate: 3 parts

[0078] Zinc oxide: 4 parts

[0079] Boron nitride: 5 parts

[0080] Phenyl silicone rubber: 8 parts

[0081] Phenyl silicone oil: 8 parts

[0082] Polyimide: 10 parts

[0083] Stearic acid: 1 part

[0084] Paraffin: 2 parts

[0085] 2-Mercaptobenzimidazole: 0.5 parts

[0086] 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane: 5 parts

[0087] 2,2,4-Trimethyl-1,2-dihydroquinoline: 0.5 parts.

[0088] The preparation method of the cable material is the same as in Example 1.

[0089] The present invention provides an idea and method for making a radiation-resistant halogen-free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com