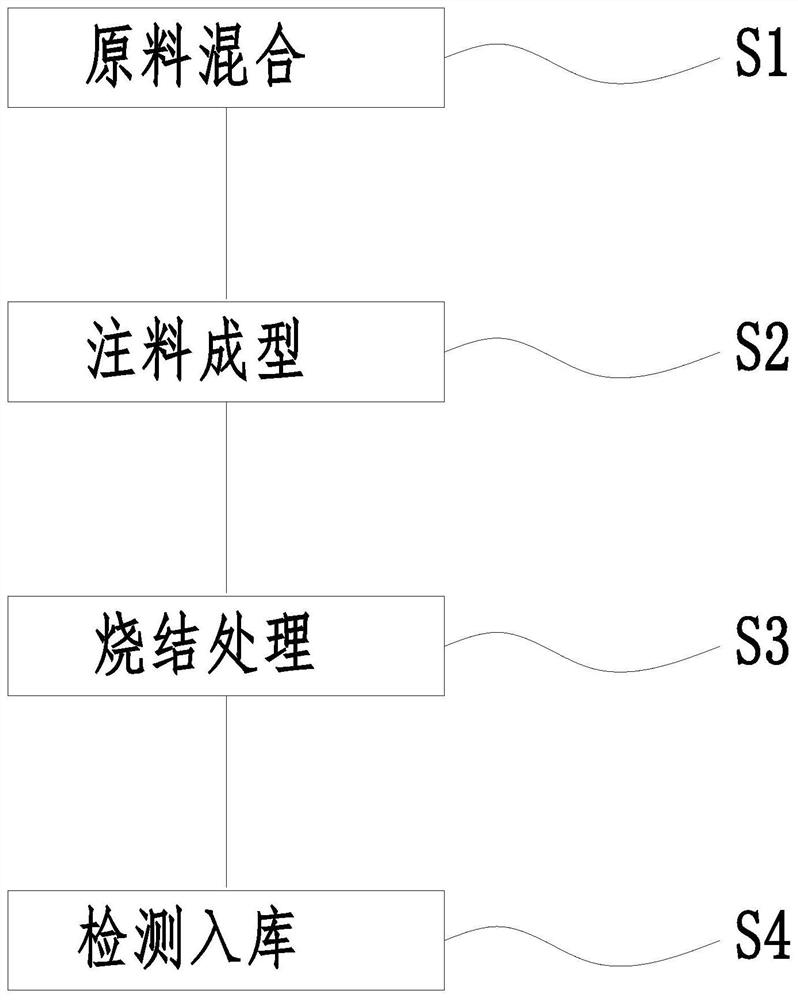

Grinding wheel manufacturing and forming process

A forming process and grinding wheel technology, which is applied in the direction of manufacturing tools, metal processing equipment, mixers, etc., can solve the problems of inability to eject the grinding wheel, poor material injection effect, and low precision of the grinding wheel, so as to facilitate subsequent forming processing and improve service life. , good adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

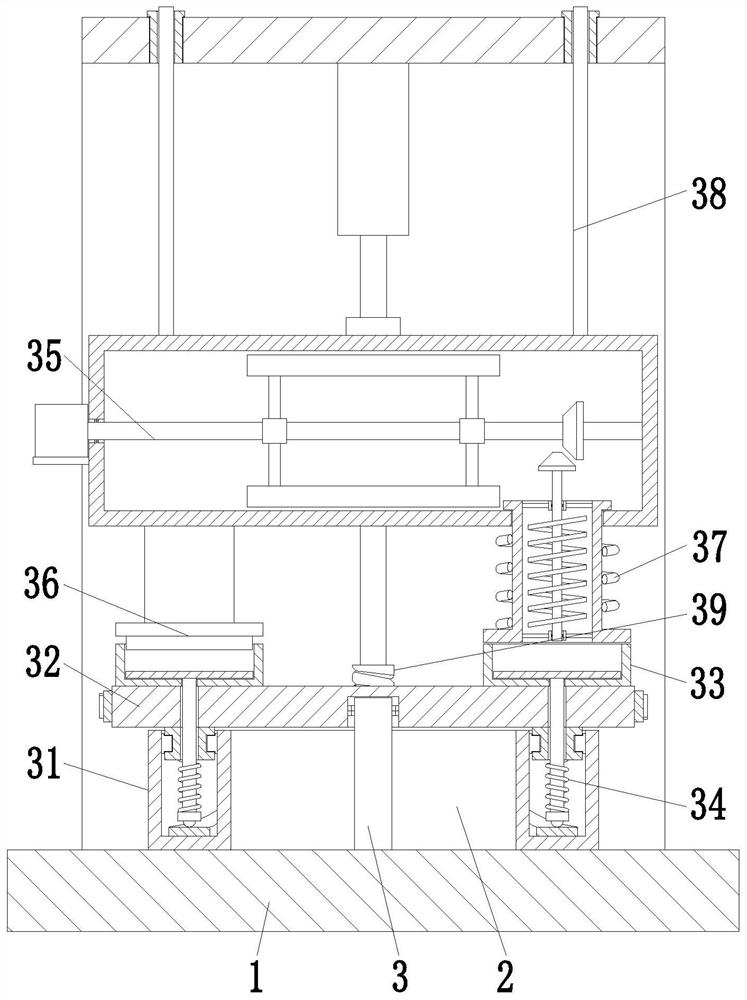

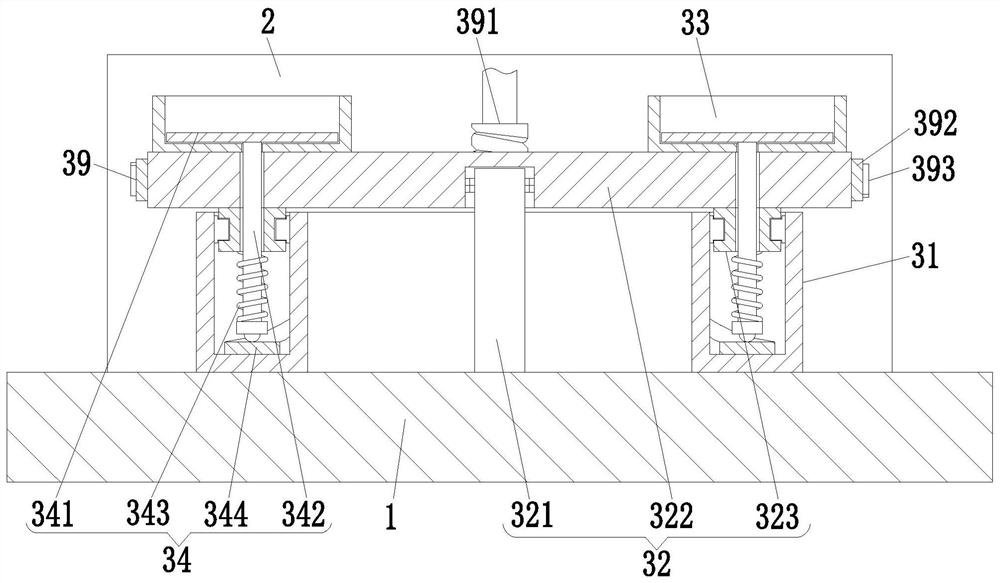

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0033] Such as Figure 1 to Figure 6 As shown, a grinding wheel forming process, the grinding wheel forming process adopts the following processing equipment, the processing equipment includes a base plate 1, a fixed frame 2 and a molding device 3, the upper end of the base plate 1 is equipped with a fixed frame 2, a fixed frame 2 The cross-section is U-shaped structure, and a forming device 3 is installed inside the fixing frame 2 , and the lower end of the forming device 3 is installed on the bottom plate 1 .

[0034]The molding device 3 includes a support frame 31, a supporting unit 32, a molding seat 33, a jacking unit 34, a mixing box 35, an extrusion die 36, a material injection unit 37, a lifting unit 38 and a rotating unit 39. The support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com