Polymer purifying method and facility, solution film forming method and facility, and flocculent and granular deposited polymer

A technology of polymer solution and purification method, which is applied in the field of flocculent and granular precipitated polymers to achieve the effects of efficient production, continuous polymer purification, and fewer foreign matter failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

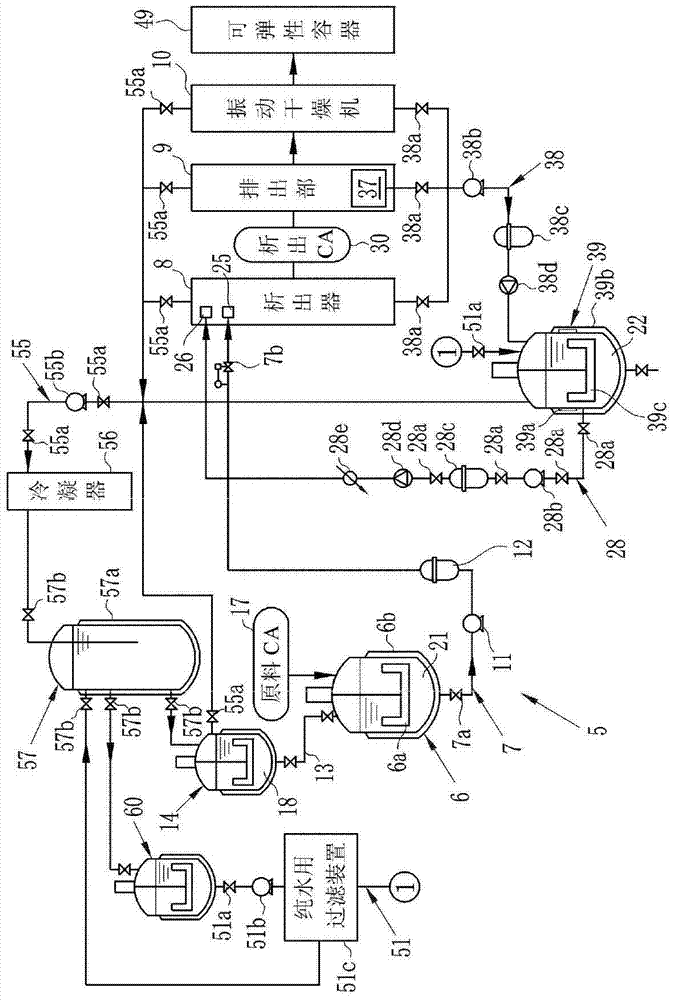

Image

Examples

Embodiment 1

[0244] Table 1 below shows the results of comparing precipitated CA (Example 1) purified by the method of the present invention with conventionally used raw material CA (Comparative Example 1). In Example 1, the solubility limit (solid content concentration) when cellulose acylate was dissolved in a mixed solvent of dichloromethane and methanol (methanol) was investigated, and about 17% was the limit in Comparative Example 1, and it was about 17% in Example 1. 24%, thus judging that the solubility limit was increased. In addition, as an essential process, the step of heating and concentrating was necessary in Comparative Example 1, but this step was not required in Example 1, and it could be achieved only by dissolution using a dissolution tank. In the subsequent casting step, both Example 1 and Comparative Example 1 were cast at a solid content concentration of about 20%.

[0245] [Table 1]

[0246]

Embodiment 2

[0248] by image 3 The equipment shown above casts the casting stock solution of Example 1 and the casting stock solution of Comparative Example 1 (both with a solid content concentration of about 20%) to obtain a film. Regarding the film obtained from the casting stock solution of Example 1 (Example 2), the film obtained from the casting stock solution of Comparative Example 1 without filtrate (Comparative Example 2), and the film of Comparative Example 1 For each size of the foreign matter, 1 square millimeter (mm) (mm 2 ) in the number of foreign objects.

[0249] When investigating the respective numbers per unit area of small-sized foreign matter of less than 10 μm, medium-sized foreign matter of 10 μm or more and less than 30 μm, and large-sized foreign matter of 30 μm or more, in the unfiltered stock solution of Comparative Example 2, the raw material The foreign matter contained in CA appeared directly in the product, about 5 small-sized foreign matter, about 30 me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com